Heat-insulating heat-preserving coating and preparation method thereof

A heat insulation and coating technology, applied in the field of coatings, can solve problems such as poor thermal insulation effect, achieve high cost performance, low raw material cost, and good water and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

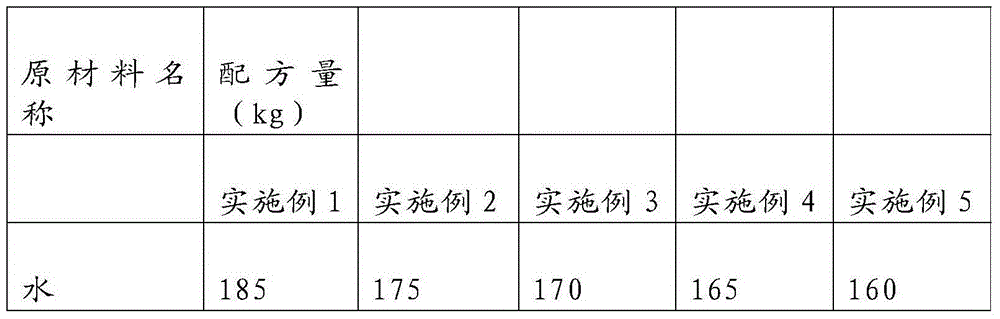

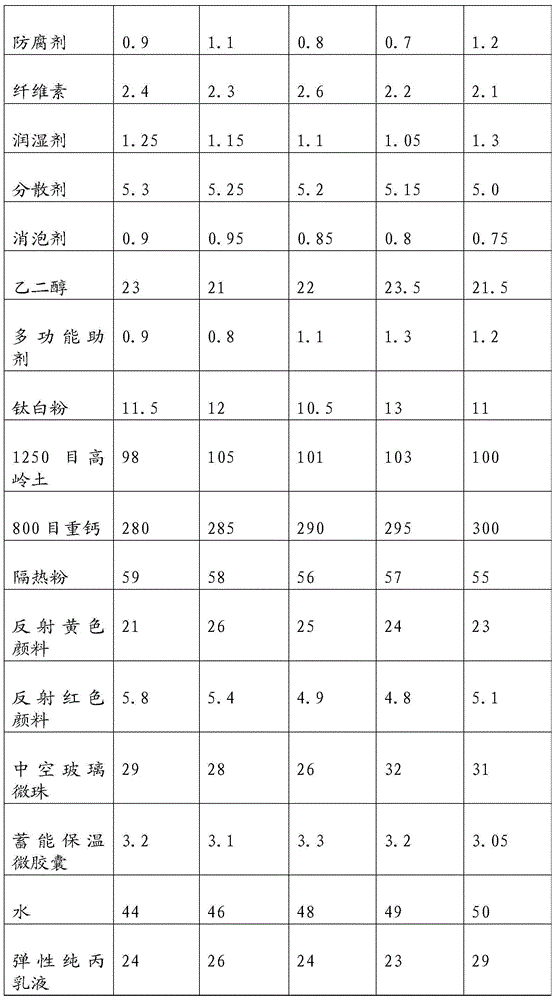

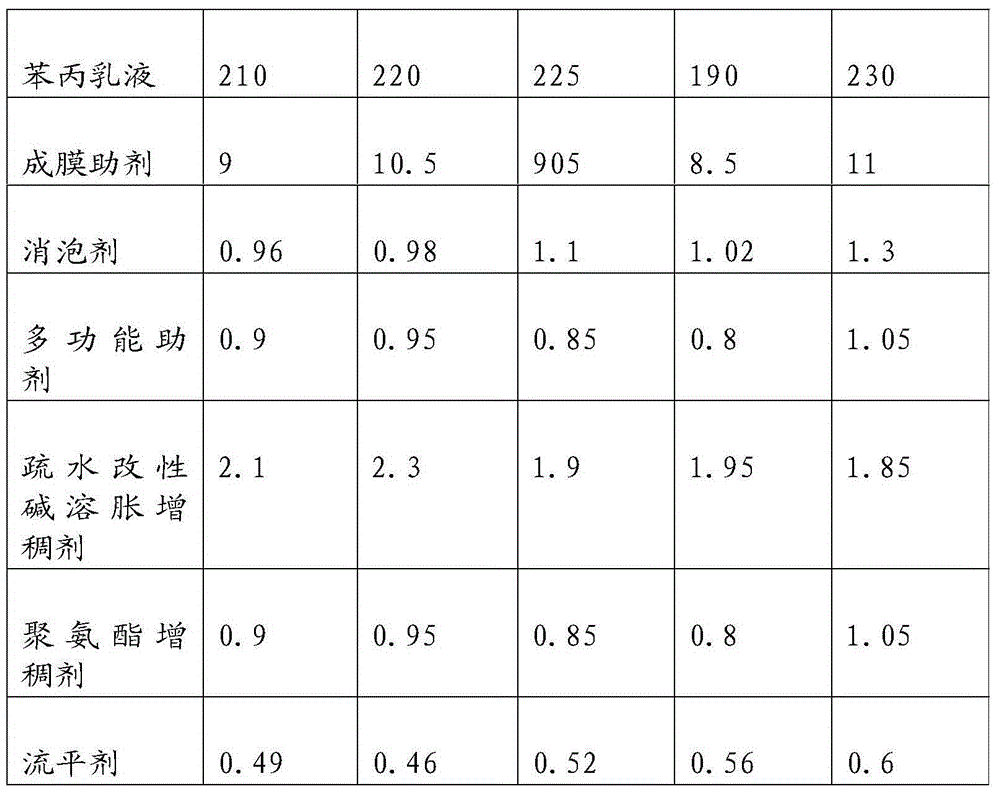

[0061] A formula of thermal insulation coating is shown in Table 2.

[0062] Table 2 The formula of Experimental Example 1

[0063]

[0064]

[0065]

[0066] The preparation method of above-mentioned coating is:

[0067] ① First add water to the production tank, turn on the high-speed disperser equipment, and adjust the dispersion speed to 350r / min. Add raw materials No. 2-8 in sequence, adjust the dispersion speed to 400r / min, and disperse and stir for 5 minutes to enter the next process stage;

[0068] ② Adjust the dispersion speed to 800r / min-1200r / min (adjusted according to the production volume), add raw materials No. 9-14 in turn, disperse and stir for 30 minutes, and test the fineness. After the fineness is ≤ 35μm, enter the next process stage ;

[0069] ③ Adjust the dispersion speed to below 500r / min, add No. 15 raw material, disperse for 5 minutes and enter the next process stage;

[0070] ④ Adjust the dispersion speed to below 300r / min, add raw material...

experiment example 2

[0078] A formula of thermal insulation coating is shown in Table 4.

[0079] Table 4 The formula of Experimental Example 2

[0080]

[0081]

[0082] The preparation method of the above coating is the same as in Experimental Example 1.

[0083] The detection results of this experimental example are shown in Table 5.

[0084] Table 5 Test results of Experimental Example 2

[0085] Fineness

experiment example 3

[0087] A formula of thermal insulation coating is shown in Table 6.

[0088] Table 6 The formula of Experimental Example 3

[0089]

[0090]

[0091] The preparation method of the above coating is the same as in Experimental Example 1.

[0092] The detection results of this experimental example are shown in Table 7.

[0093] Table 7 Test results of Experimental Example 3

[0094] Fineness

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com