A kind of anti-rust paint prepared by using blue carbon wastewater and its preparation method

A technology of semi-carbon wastewater and anti-rust coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of waste of resources, high investment costs, pollution of the environment, etc., and achieve the effects of low cost, long anti-rust life, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Put 100 parts by weight of semi-coke wastewater, 3 parts by weight of formaldehyde and 5 parts by weight of hexamethylenetetramine into the reaction kettle, stir, and use the heat carried by the semi-coke wastewater as the heat source, and keep it warm at 90°C for 2 hours ;

[0028] (2) Under stirring, add 8 parts by weight of polyvinyl alcohol, 30 parts by weight of mica iron oxide, and 0.3 parts by weight of sodium hydroxymethylcellulose, and keep warm for 2 hours;

[0029] (3) After the reaction, put the materials into a high-speed mixer, add 10 parts by weight of mica powder, 90 parts by weight of kaolin, and 0.5 parts by weight of n-amyl alcohol, and stir for 4 hours;

[0030] (4) Grind with a colloid mill for 1 hour, discharge the material once, and pack to obtain the antirust coating.

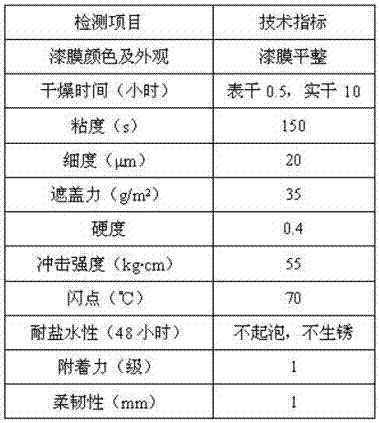

[0031] The antirust paint prepared by the present embodiment is tested for relevant indicators according to national testing standards, and its data are shown in the followin...

Embodiment 2

[0034] (1) Put 100 parts by weight of semi-coke wastewater, 2 parts by weight of formaldehyde and 3 parts by weight of melamine into the reaction kettle, stir, and use the heat carried by the semi-coke wastewater as the heat source, and keep it warm at 92°C for 1 hour;

[0035] (2) Under stirring, add 8 parts by weight of polyvinyl alcohol, 25 parts by weight of iron oxide red, and 0.5 parts by weight of sodium hydroxymethylcellulose, and keep warm for 2 hours;

[0036] (3) After the reaction, put the materials into a high-speed mixer, add 9 parts by weight of mica powder, 85 parts by weight of kaolin, and 0.3 parts by weight of n-butanol, and stir for 3 hours;

[0037] (4) Grind with a colloid mill for 2 hours and discharge once, then pack to obtain the antirust coating.

Embodiment 3

[0039] (1) Put 100 parts by weight of semi-coke wastewater, 3 parts by weight of formaldehyde and 2 parts by weight of polyamide into the reaction kettle, stir, use the heat carried by the semi-coke wastewater as the heat source, and keep warm for 2 hours;

[0040] (2) Under stirring, add 9 parts by weight of polyvinyl alcohol, 20 parts by weight of iron oxide red, and 0.3 parts by weight of sodium hydroxymethylcellulose, and keep warm for 1 hour;

[0041] (3) After the reaction, put the materials into a high-speed mixer, add 10 parts by weight of mica powder, 90 parts by weight of kaolin, and 0.1 parts by weight of polymethylsiloxane emulsion, and stir for 6 hours;

[0042] (4) Grind with a colloid mill for 1 hour, discharge the material once, and pack to obtain the antirust coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com