Preparation method of regenerated cellulose fiber subjected to cation grafting modification and salt-free dyeing

A technology of regenerated cellulose and cationic modifier, applied in the chemical post-processing of cellulose/protein man-made filaments, etc., can solve the problems of dye waste, uneven dyeing, increase process flow, etc., and achieve the effect of avoiding dye waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

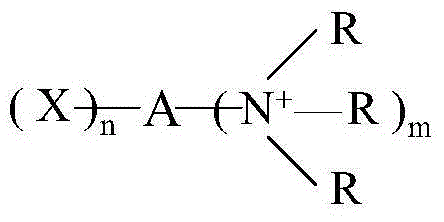

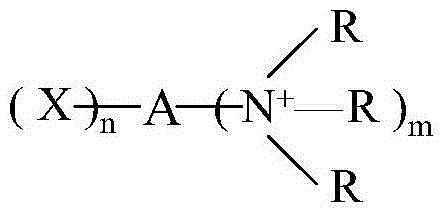

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Cotton pulp with a degree of polymerization of 550 and a cellulose content of 95% was used to prepare a spinning viscose solution through successive processes of dipping, pressing, crushing, aging, yellowing, dissolving, filtering, and defoaming. During the dissolving process of cellulose, add a polypropylene oxide amine compound (condensed by epichlorohydrin and diethylenetriamine dicyandiamide) equivalent to 0.1% of methyl cellulose to obtain 8.0% of methyl cellulose, NaOH 6%, viscosity (falling ball method) 60s, maturity (10% NH 4 Cl) 17ml, viscose esterification degree is the cellulose xanthate spinning dope of 35; Adopt wet spinning procedure to spin. The spinneret specification is 20000 holes × 0.05mm, the spinning speed is 50m / min, and the coagulation bath is composed of: sulfuric acid 120g / L, sodium sulfate 300g / L, zinc sulfate 10g / L. The main indexes of the fiber prepared through the above steps are as follows: fineness 1.60dtex; dry strength 2.23CN / dtex; wet ...

Embodiment 2

[0027] Using wood pulp with a polymerization degree of 500 and a cellulose content of 92%, the spinning viscose solution is prepared through processes such as dipping, pressing, crushing, aging, yellowing, dissolving, filtering, and defoaming. In the pre-spinning injection process (relative to the spinning process), a polyepoxy cationic modifier equivalent to 6% of the methyl fiber is added to obtain a 8.0% methyl fiber, NaOH 6%, a viscosity (falling ball method) of 55s, and a maturity (10%NH 4 Cl) 18ml, viscose degree of esterification is the cellulose xanthate spinning stock solution of 40; Adopt wet spinning procedure to spin. The size of the spinneret is 20000 holes × 0.05mm, the spinning speed is 55m / min, and the coagulation bath composition is: sulfuric acid 100g / L, sodium sulfate 300g / L, zinc sulfate 12g / L. The main indexes of the fiber prepared through the above steps are as follows: fineness 1.52dtex; dry strength 2.3CN / dtex; wet strength 1.48CN / dtex; dry elongation ...

Embodiment 3

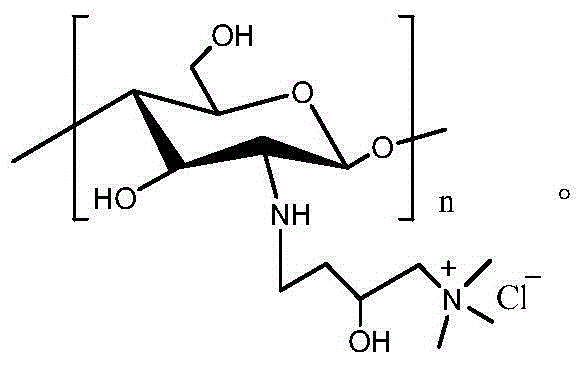

[0031] The bamboo pulp with a degree of polymerization of 570 and a cellulose content of 94% is used to prepare a spinning viscose solution through successive processes of dipping, pressing, crushing, aging, yellowing, dissolving, filtering, and degassing. In the post-dissolving process of cellulose, add the modified chitosan equivalent to 12% of methyl cellulose to obtain 8.9% of methyl cellulose, 5.8% of NaOH, viscosity (falling ball method) 50s, maturity (10% NH 4 Cl) 16ml, viscose esterification degree is the cellulose xanthate spinning dope of 38; Adopt wet spinning procedure to spin. The size of the spinneret is 20000 holes × 0.05mm, the spinning speed is 50m / min, and the coagulation bath composition is: sulfuric acid 110g / L, sodium sulfate 280g / L, zinc sulfate 10g / L. The main indexes of the fiber prepared through the above steps are as follows: fineness 1.64dtex; dry strength 2.14CN / dtex; wet strength 1.38CN / dtex; dry elongation 16.8%.

[0032] The modified chitosan st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com