Destructive distillation method and device for organic solid waste harmless treatment

A technology for harmless treatment of organic solids, applied in combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of uneven heating, large energy consumption, affecting dry distillation efficiency, etc., to improve drying and dry distillation efficiency, The effect of saving energy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

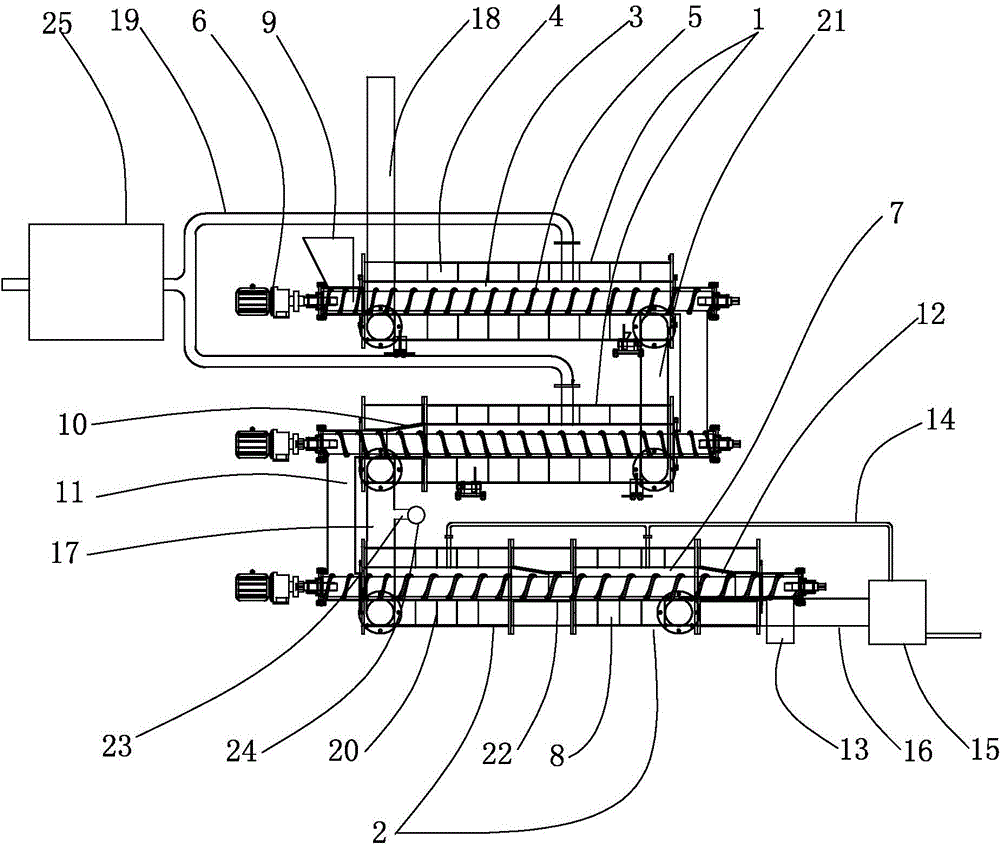

[0032] A dry distillation method for the harmless treatment of organic solid waste provided by the present invention comprises the following steps:

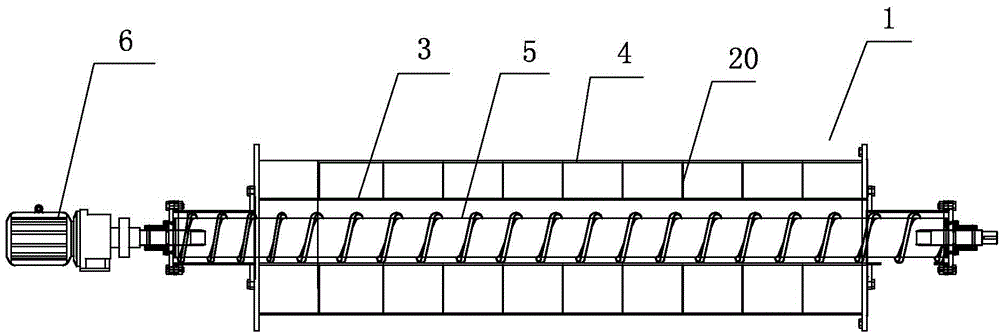

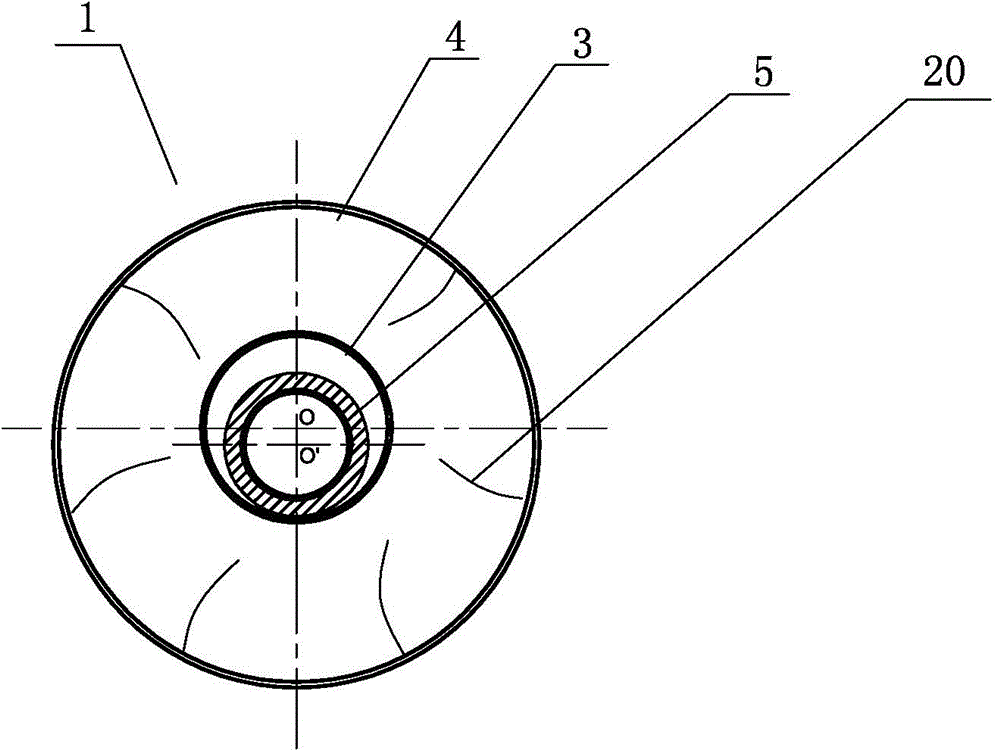

[0033] (1) A drying chamber for drying materials and a retort chamber for carbonizing materials are provided, and a drying chamber heating chamber and a retort chamber heating chamber are respectively arranged around the drying chamber and the retorting chamber;

[0034](2) Send the material to be dry-distilled into the drying chamber, and lead the high-temperature hot air to the heating chamber of the drying chamber through the hot gas pipeline, and heat the drying chamber so that the moisture content of the material in the drying chamber is reduced to below 10%; the water produced in the drying chamber is The steam is discharged to the drying room; the dried material is pushed into the closed retort room;

[0035] (3) Lead the high-temperature hot gas to the heating chamber of the retort chamber through the hot gas pipeline, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com