Automatic 350 g bean curd stick forming machine

A bean curd stick forming machine and automatic technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of unfavorable bean curd skin forming, large temperature drop, etc., and achieve the effect of not easy to mold and deteriorate, reduce the number of workers, and clean the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

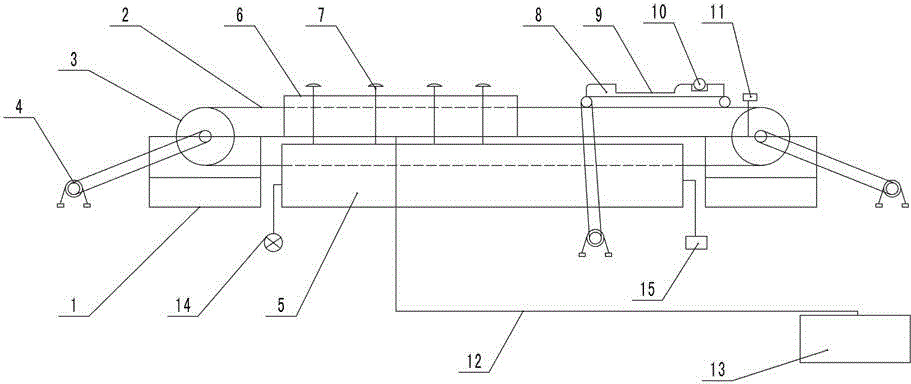

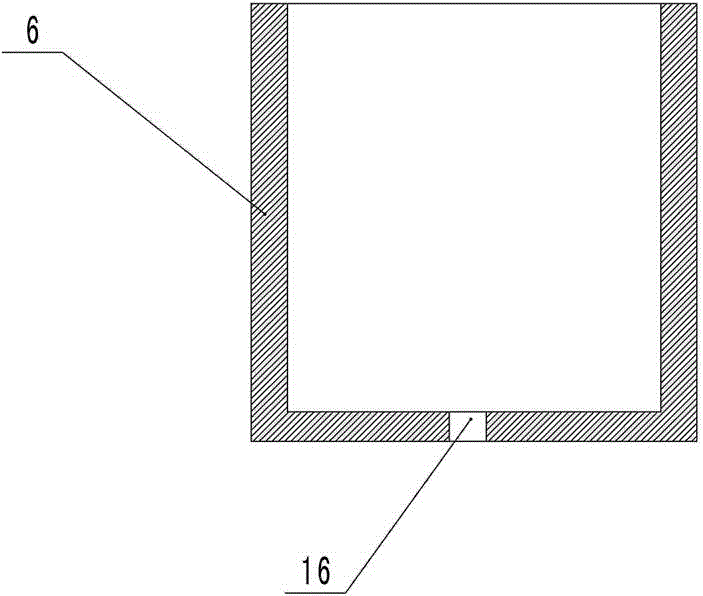

[0013] Such as figure 1 Shown is the schematic diagram of the structure of the Qiliang automatic bean curd stick forming machine. Including a bracket 1, two ends of the bracket 1 are respectively fixed with rollers 3, and the two rollers 3 are connected by a conveyor belt 2, and the roller 3 is powered by a motor 4. The length of the conveyor belt 2 is sufficient for the needs of the production site. The forming machine also includes a raw pulp heating container 5, from which several spraying devices 7 are stretched out from the raw pulp heating container 5, and the nozzles of the spraying devices 7 are arranged against the conveyor belt 2, and the raw pulp heating container 5 is connected with a pressure pump 14 and automatic constant temperature controller 15.

[0014] The conveyor belt 2 is also provided with a forming mobile car 8 powered by a motor. The forming mobile car 8 is provided with a slurry heating container 9 and a forming wheel 10 driven by the motor. The rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com