Silage processing method of switchgrass

A processing method and technology of willow branches, applied in the field of agriculture, can solve problems such as unsatisfactory results, and achieve the effects of improving fermentation level, low cost, and low pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1 composite bacterial agent

[0024] Inoculate Lactobacillus plantarum, Bacillus subtilis, and Lactococcus lactis into MRS-S medium respectively, and culture them statically at 30°C for 72 hours. The ratio of the number of forming units is 94:4.5:1.5, and the total number of colony forming units is 1×10 12 CFU / ml, the silage inoculant is obtained.

Embodiment 2

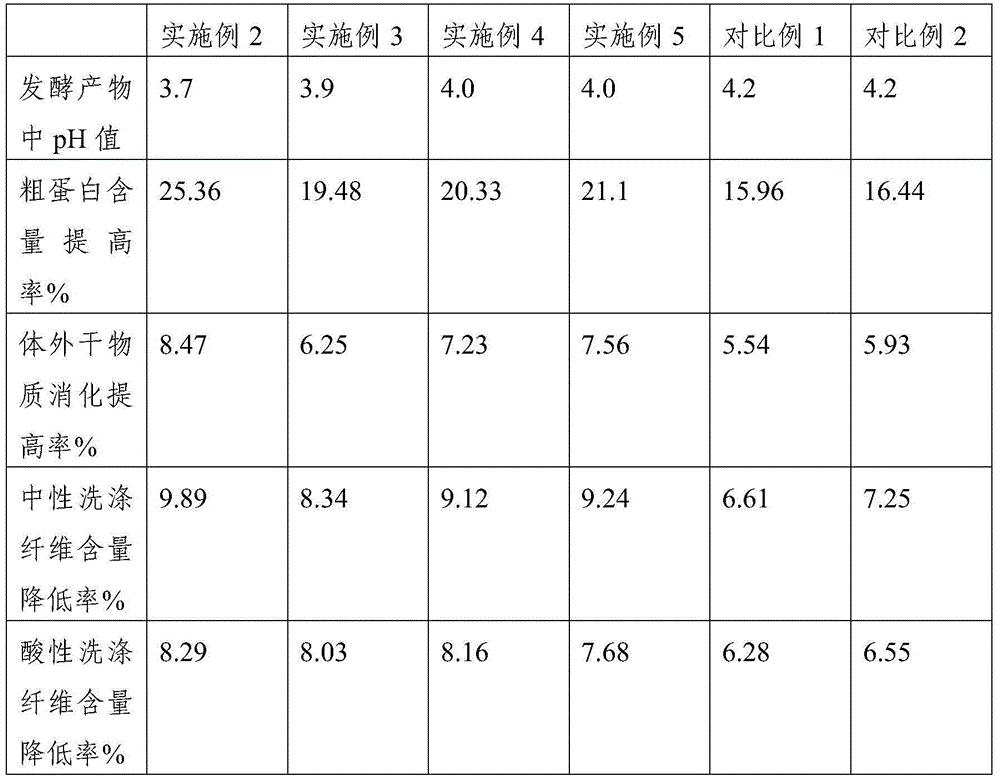

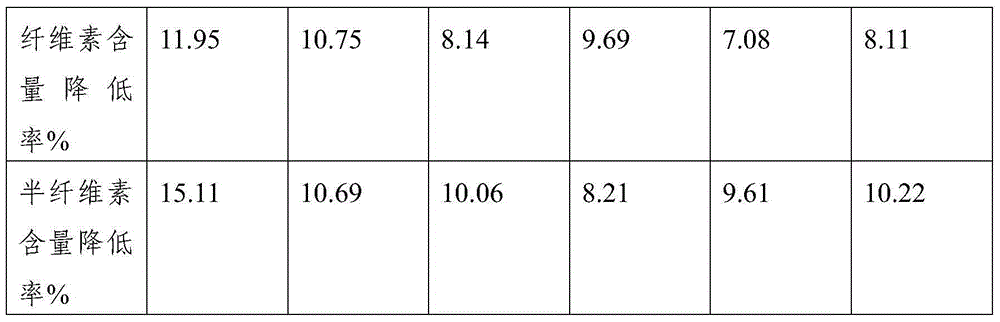

[0025] Embodiment 2 switchgrass silage processing method

[0026] Proceed as follows:

[0027] Mix the composite bacterial agent obtained in Example 1 with cellulose complex enzyme C9748, add a small amount of water to evenly sandblast the surface of the switchgrass, and wherein the composite bacterial agent is added in an amount of 5.2×10 7 CFU / gFM, the amount of cellulose compound enzyme added is 8mg / Kg DM; put the switchgrass into a 2L screw bottle, compact and seal it, and carry out anaerobic fermentation for 30 days.

Embodiment 3

[0028] Embodiment 3 switchgrass silage processing method

[0029] Ferment according to the silage processing method described in embodiment 2, difference is:

[0030] 1) The cellulose complex enzyme is disintegrating enzyme D9515, CAS No. 85186-71-6, derived from Basidiomycetes sp., purchased from Sigma-Aldrich;

[0031] 2) The amount of compound bacterial agent added is 4.5×10 7 CFU / g FM, the added amount of cellulose compound enzyme is 10mg / Kg DM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com