Electronic cigarette smoke solution prepared through oolong leaf extract

A technology of e-cigarette liquid and tea extract, which is applied in the field of e-cigarettes, can solve problems such as insufficient aroma and poor taste, and achieve the effect of solving insufficient aroma and taste, rich aroma, and harmonious aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

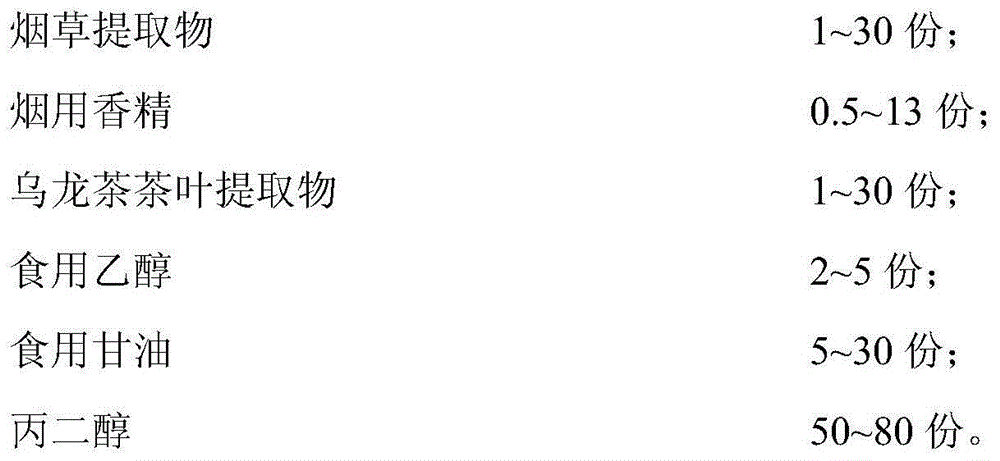

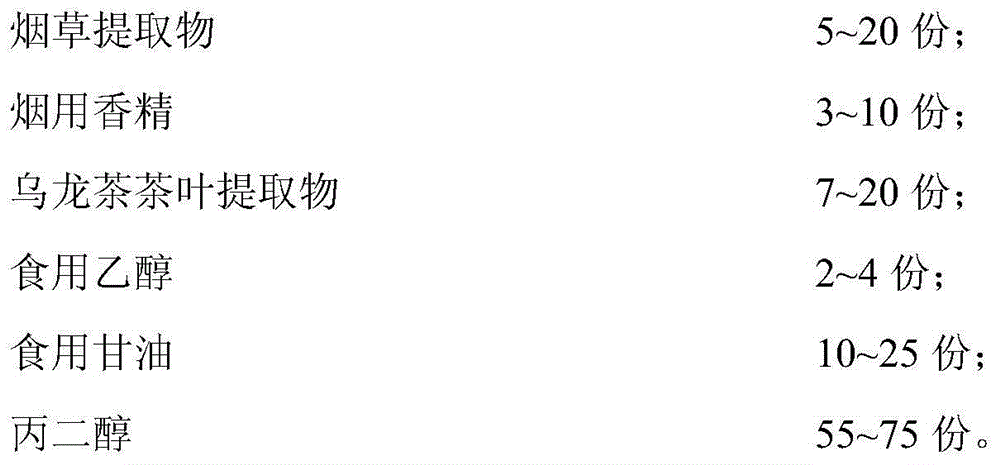

Method used

Image

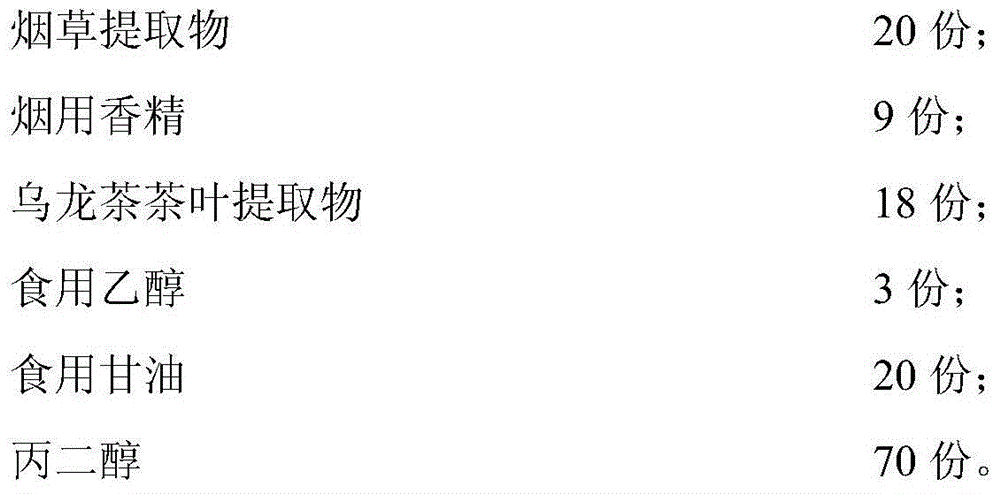

Examples

Embodiment 1

[0063] The preparation of the tobacco extract in this example: take a sample of flue-cured tobacco leaves of Luzhou-flavor type, dry in an oven at 40° C. for 3 hours, cool to room temperature, and crush to 40-60 mesh. Weigh 100g of tobacco powder into a 1L Erlenmeyer flask, add 300mL of deionized water, conduct ultrasonic extraction at 50±5°C for 4 hours, then let it settle for 4 hours, filter it with a sand core funnel to obtain the filtrate, and depressurize at 70±10°C Concentrate to 3mL by rotary evaporation to obtain tobacco extract.

[0064] In this example, the oolong tea leaves are Tieguanyin tea leaves, and the extraction method of Tieguanyin tea extract is as follows: weigh 100 g of Tieguanyin tea leaves, grind them into 20-30 mesh powders with a pulverizer, put them into a 1L extraction kettle, and control the extraction pressure is 25MPa, the extraction temperature is 45°C, and the supercritical CO 2 The flow rate is 25L / h, and the extraction time is 3h. After ext...

Embodiment 2

[0069] Preparation of the tobacco extract in this example: Burley tobacco leaf samples were dried in an oven at 40° C. for 3 hours, cooled to room temperature, and crushed to 40-100 meshes. Weigh 100g of tobacco powder into a 1L Erlenmeyer flask, add 300mL of deionized water, ultrasonically extract at 50±5°C for 4 hours, then let it settle for 4 hours, filter with a sand core funnel to obtain the filtrate, and decompress at 70±10°C Concentrate to 3mL by rotary evaporation to obtain tobacco extract.

[0070] In this example, the oolong tea leaves are Dahongpao tea leaves, and the extraction method of Dahongpao tea extract is as follows: weigh 100 g of Dahongpao tea leaves, grind them into 20-30 mesh powders with a pulverizer, put them into a 1L extraction kettle, and control the extraction pressure is 25MPa, the extraction temperature is 45°C, and the supercritical CO 2 The flow rate is 25L / h, and the extraction time is 3h. After extraction, the supercritical fluid in which t...

Embodiment 3

[0075] Tobacco extract preparation in this example: take a sample of sun-cured tobacco leaf and dry it in an oven at 40° C. for 3 hours, cool it down to room temperature, and crush it to 40-100 mesh tobacco powder. Weigh 100g of tobacco powder and place it in a 1L Erlenmeyer flask, add 300mL of deionized water, conduct ultrasonic extraction at 50±5°C for 4 hours, then let it settle for 4 hours, filter through a sand core funnel to obtain the filtrate, and concentrate it by rotary evaporation under reduced pressure to 3mL to obtain the tobacco extract.

[0076] In the present embodiment, the oolong tea leaves are golden osmanthus, and the extraction method of the golden osmanthus tea extract is as follows: take 100 g of golden osmanthus, grind it into 20-30 mesh powder through a pulverizer, put it into a 1L extraction kettle, and control the extraction pressure to 25MPa, the extraction temperature is 45°C, and the supercritical CO 2 The flow rate is 25L / h, and the extraction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com