Coating for intervention catheter, preparation method of coating, and intervention catheter

An interventional catheter and coating technology, applied in the field of interventional catheter coatings and interventional catheters, can solve the problems of insufficient firmness of the hydrophilic coating on the surface of interventional catheters, and achieve outstanding practical application effects, excellent wear resistance, and a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

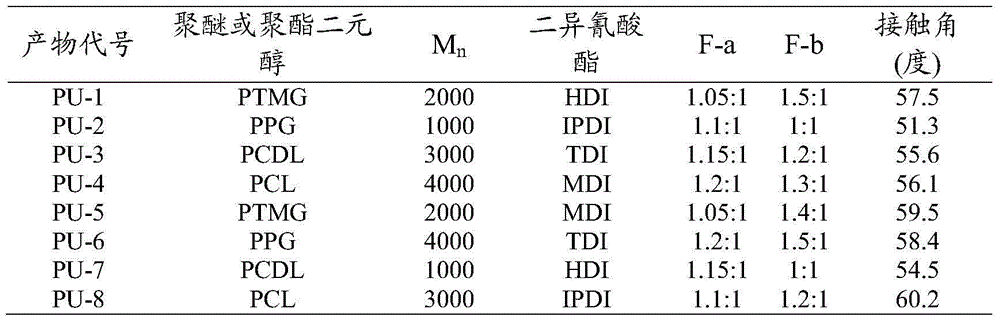

preparation example Construction

[0054] In addition, the present invention also provides a preparation method of a coating for an interventional catheter, comprising the following steps:

[0055] Preparation of primer: Add side carboxyl group-containing polyurethane, polyglycidyl acrylate and organic solvent into a container, stir at room temperature for 20-60 minutes to obtain primer; in the obtained primer, side carboxyl group-containing polyurethane and polyacrylic glycidyl The mass ratio of the ester is 1:(0.1-1), and the mass of the organic solvent is 80wt%-99wt% of the total mass of the primer.

[0056] Preparation of top coat: Add side carboxyl group-containing polyurethane, polymethyl vinyl ether-maleic anhydride and organic solvent into a container, stir at room temperature for 20-60 min to obtain top coat; in the obtained top coat, side carboxyl group-containing polyurethane The mass ratio of polymethyl vinyl ether-maleic anhydride is 1:(0.1-10), and the mass of the organic solvent is 80wt%-99wt% of...

Embodiment 1

[0085] S100: Add side carboxyl group-containing polyurethane PU-1, polyglycidyl acrylate sample 1 and N,N-dimethylacetamide into a container, and stir at room temperature for 30 minutes to obtain a primer. In the primer, the mass ratio of PU-1 to polyglycidyl acrylate is 1:0.1, and the mass of N,N-dimethylacetamide is 95% by weight of the total mass of the primer.

[0086] S200: adding side carboxyl group-containing polyurethane PU-1, polymethyl vinyl ether-maleic anhydride and ethyl acetate into a container, and stirring at room temperature for 30 minutes to obtain a top coat. In the top coat, the mass ratio of PU-1 to polymethyl vinyl ether-maleic anhydride is 1:8, and ethyl acetate is 90wt% of the total mass of the top coat. Among them, polymethyl vinyl ether-maleic anhydride is produced by Sigma Alrich, and its number average molecular weight is 80,000.

[0087] Apply the primer obtained in S100 to the surface of the interventional catheter, and cure at 60°C for 30 minute...

Embodiment 2

[0092] S100: Add side carboxyl group-containing polyurethane PU-2, polyglycidyl acrylate sample 1 and tetrahydrofuran into a container, and stir at room temperature for 20 minutes to obtain a primer. In the primer, the mass ratio of PU-2 to polyglycidyl acrylate is 1:0.2, and the mass of tetrahydrofuran is 80 wt% of the total mass of the primer.

[0093] S200: adding side carboxyl group-containing polyurethane PU-2, polymethyl vinyl ether-maleic anhydride and methylene chloride into a container, and stirring at room temperature for 20 minutes to obtain a top coat. In the top coat, the mass ratio of PU-2 to polymethyl vinyl ether-maleic anhydride is 1:10, and methylene chloride is 99wt% of the total mass of the top coat. Among them, polymethyl vinyl ether-maleic anhydride is produced by Sigma Alrich, and its number average molecular weight is 80,000.

[0094]Apply the primer obtained in S100 to the surface of the interventional catheter, and cure at 40°C for 60 minutes; then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com