A coating for forming a hydrophilic coating on the surface of catheter and its preparation and use method

A technology of hydrophilic coating and primer, applied in the field of medical devices, can solve the problems of toxicity of isocyanate compounds, insufficient coating firmness, insufficient coating wear resistance, etc., and achieve excellent wear resistance, compensation performance and function Insufficient, the effect of low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

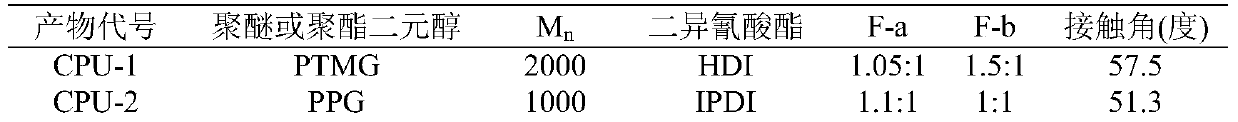

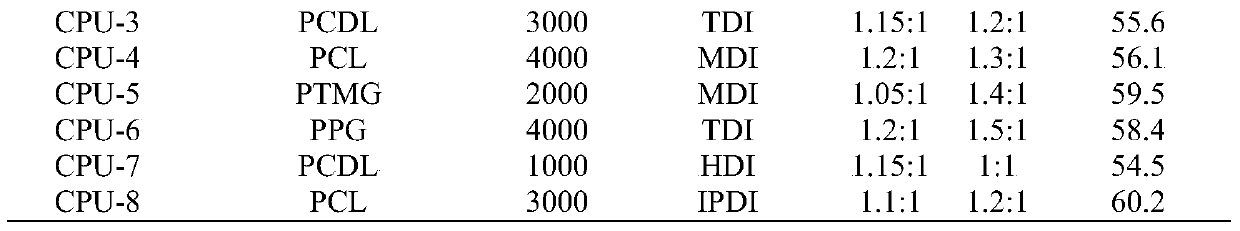

[0041] Preparation of side carboxyl group-containing polyurethane (CPU): use solvent method to synthesize side carboxyl group-containing polyurethane, add polyether or polyester diol and diisocyanate into the reactor, heat up to 80°C, stir for 1 hour to obtain prepolymer, Add 2,2-dimethylol propionic acid and 1,4-butanediol, react for 2 hours, add N,N-dimethylformamide, continue the reaction for 1 hour, add dibutyltin dilaurate, and then Reacted for 8 hours, down to room temperature, the solution in the reactor was poured into a container with deionized water, a white precipitate was precipitated, collected the precipitate and washed 3 times with deionized water, placed in a vacuum drying oven, at 90 After vacuum drying at ℃ for 48 hours, a transparent block product was obtained, which was granulated to obtain a side carboxyl group-containing polyurethane masterbatch.

[0042] Wherein, described polyether or polyester diol is selected from polyoxypropylene diol (PPG), polytetr...

Embodiment 2

[0049] Water-based polyurethane, trimethylolpropane-tris[3-(2-methylaziridinyl)]propionate, and deionized water were added to the container, and stirred at room temperature for 30 minutes to obtain a primer, in which three The quality of methylolpropane-tris[3-(2-methylaziridinyl)]propionate is 1% of the waterborne polyurethane quality, and the quality of deionized water is 80% of the total quality of the primer. Add side carboxyl group-containing polyurethane CPU-1, polymethyl vinyl ether-maleic anhydride, polyethylene glycol monomethyl ether, and N,N-dimethylformamide into the container, and stir at room temperature for 30 minutes to obtain Top coat, wherein the mass ratio of CPU-1 to polymethyl vinyl ether-maleic anhydride is 1:0.1, and the quality of polyethylene glycol monomethyl ether is 1% of the mass of polymethyl vinyl ether-maleic anhydride , The quality of N,N-dimethylformamide is 80% of the total mass of the top coat. Polymethyl vinyl ether-maleic anhydride is a p...

Embodiment 3

[0054] Water-based polyurethane, trimethylolpropane-tris(3-aziridinyl)propionate, and deionized water were added to the container, and stirred at room temperature for 30 minutes to obtain a primer, wherein trimethylolpropane-tris(3-aziridinyl)propionate The quality of (3-aziridinyl) propionate is 2% of the waterborne polyurethane quality, and the quality of deionized water is 83% of the total quality of the primer. Add side carboxyl group-containing polyurethane CPU-2, polymethyl vinyl ether-maleic anhydride, polyethylene glycol monomethyl ether, and N,N-dimethylacetamide into the container, and stir at room temperature for 30 minutes to obtain Top coat, wherein the mass ratio of CPU-2 to polymethyl vinyl ether-maleic anhydride is 1:0.5, and the quality of polyethylene glycol monomethyl ether is 3% of the mass of polymethyl vinyl ether-maleic anhydride , the quality of N,N-dimethylacetamide is 83% of the total mass of the top coat. Polymethyl vinyl ether-maleic anhydride is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com