ZnO@ZIF-8 core-shell structure microsphere and preparation method thereof

A technology of ZIF-8 and core-shell structure, which is applied in the field of core-shell structure microspheres and its preparation, can solve the problems of easy agglomeration of rod-shaped products, lower specific surface area, long reaction time, etc., and achieve excellent photoelectric and piezoelectric properties, specific surface area Large, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The concrete steps of preparation are:

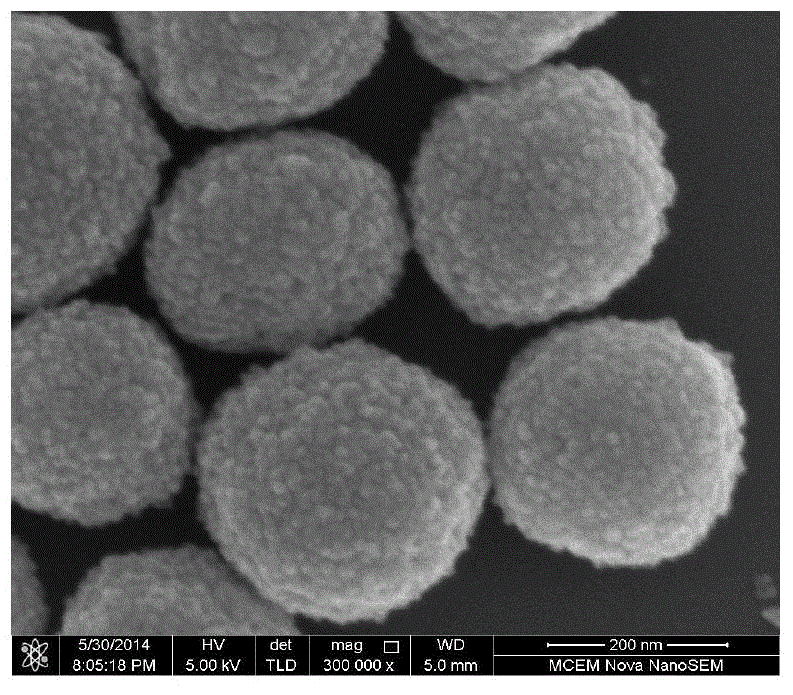

[0036] Step 1: First, according to the weight ratio of 3.5:250, zinc acetate dihydrate was added to diethylene glycol, and refluxed at 140° C. for 2 hours to obtain a reaction solution. After the reaction solution is cooled to room temperature, it is sequentially subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation process is centrifugation with a rotating speed of 2000r / min and a time of 6min, and the washing process is to use ethanol to The separated solid matter is cleaned once, and the separation of the solid matter during cleaning is centrifugation, and the drying process is to dry the cleaned solid matter at 60 ° C to obtain an approximate figure 1 Spherical ZnO shown.

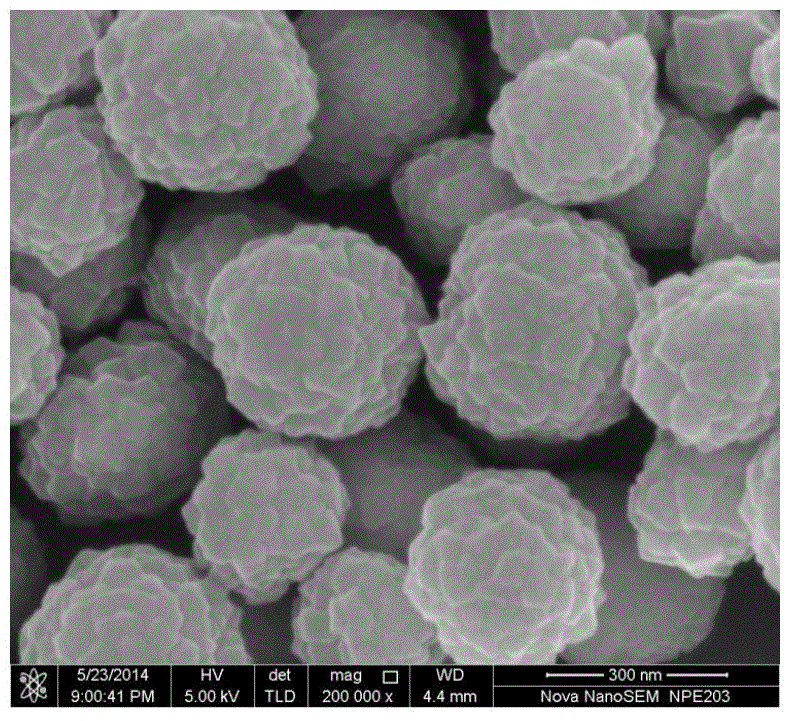

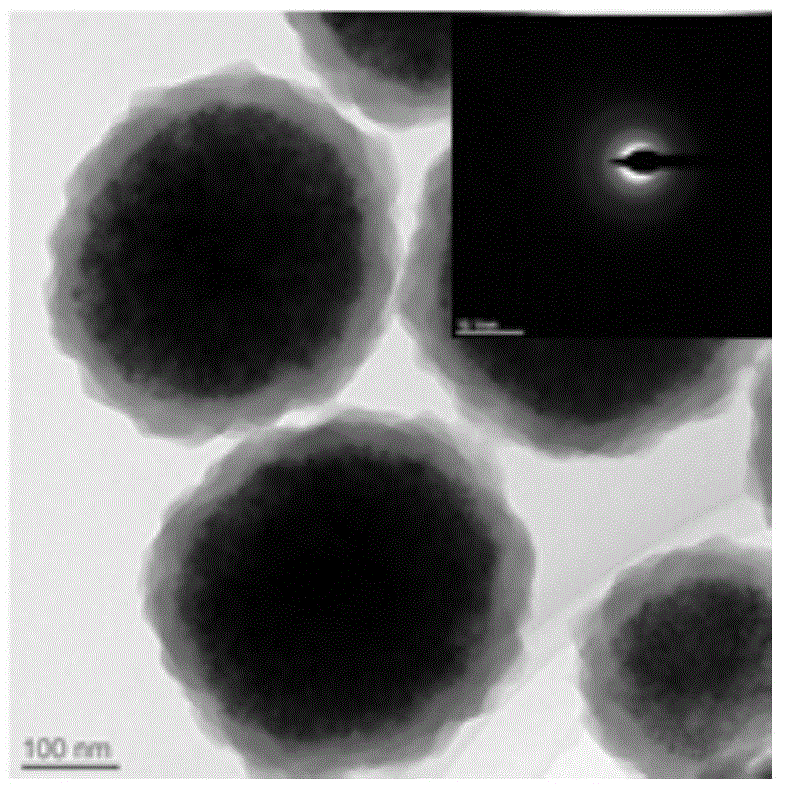

[0037] Step 2, according to the weight ratio of 0.008:2.9, adding spherical ZnO into 3.16mol / L 2-methylimidazole ethanol solution, standing and aging for 8min, followed by solid-liquid separation, washing and dryin...

Embodiment 2

[0039] The concrete steps of preparation are:

[0040] Step 1: First, according to the weight ratio of 4.5:250, zinc acetate dihydrate was added to diethylene glycol, and refluxed at 150° C. for 1.8 hours to obtain a reaction solution. After the reaction solution is cooled to room temperature, it is sequentially subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation process is centrifugation with a rotating speed of 3000r / min and a time of 5min, and the washing process is to use ethanol to The separated solids are cleaned twice, the separation of solids is centrifugation during cleaning, and the drying process is to dry the cleaned solids at 68 ° C to obtain a similar figure 1 Spherical ZnO shown.

[0041] Step 2, according to the weight ratio of 0.009:2.8, adding spherical ZnO into 3.41mol / L 2-methylimidazole ethanol solution, standing and aging for 21min, followed by solid-liquid separation, washing and drying Treatment; wherein, the...

Embodiment 3

[0043] The concrete steps of preparation are:

[0044] Step 1: First, according to the weight ratio of 5.5:250, zinc acetate dihydrate was added to diethylene glycol, and refluxed at 160° C. for 1.5 h to obtain a reaction solution. After the reaction solution is cooled to room temperature, it is sequentially subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation process is centrifugation with a rotating speed of 4000r / min and a time of 4min, and the washing process is to use ethanol to The separated solid matter is washed three times, the separation of the solid matter during cleaning is centrifugation, and the drying process is to dry the cleaned solid matter at 75°C to obtain the following: figure 1 Spherical ZnO shown.

[0045] Step 2, according to the weight ratio of 0.01:2.7, adding spherical ZnO into 3.56mol / L 2-methylimidazole ethanol solution, standing and aging for 34min, followed by solid-liquid separation, washing and drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ball diameter | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com