Crystal seed growth method for preparing gold nano-particles

A seed growth method, a technology of gold nanoparticles, applied in nanotechnology and other directions, can solve the problems of uneven morphology, toxicity, poor monodispersity of gold nanoparticles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

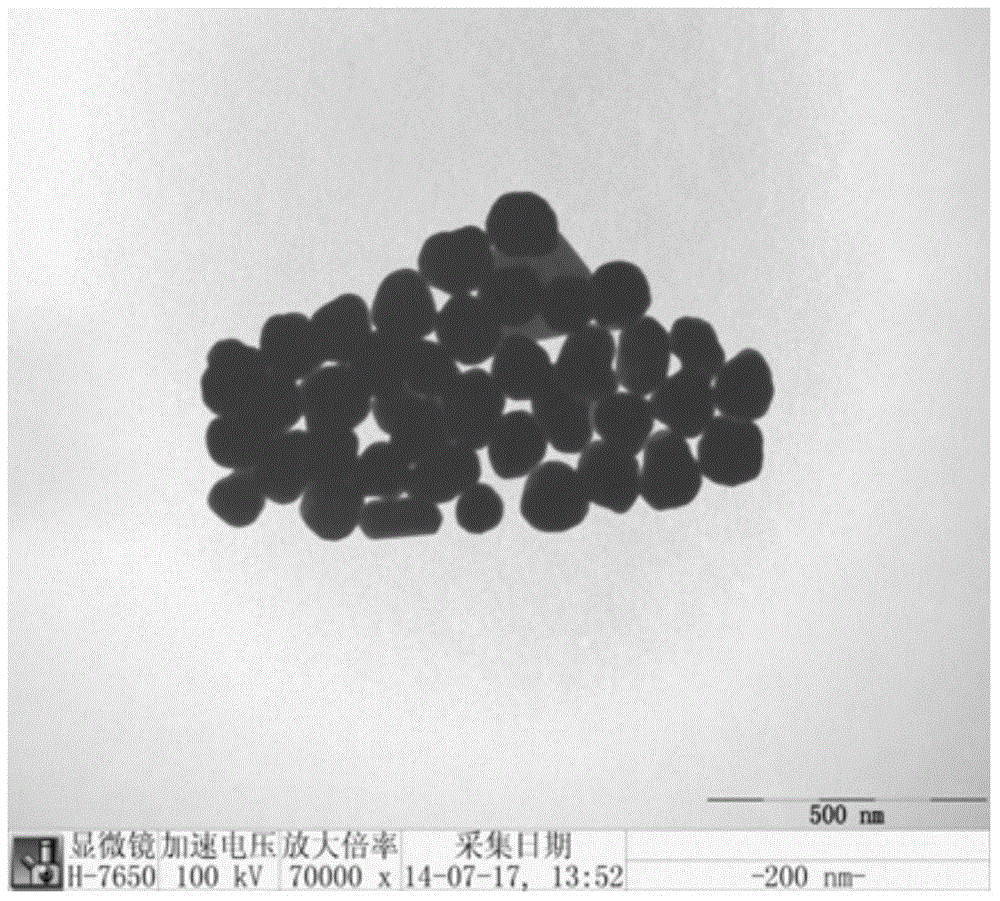

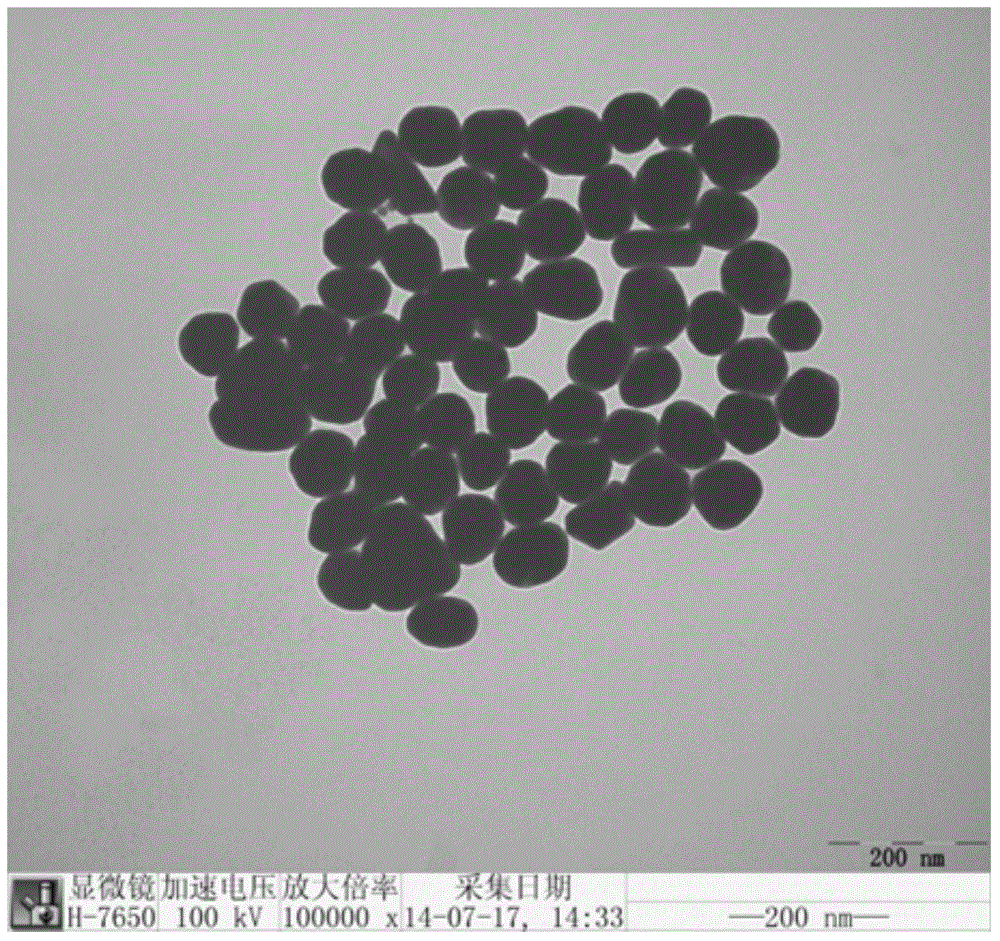

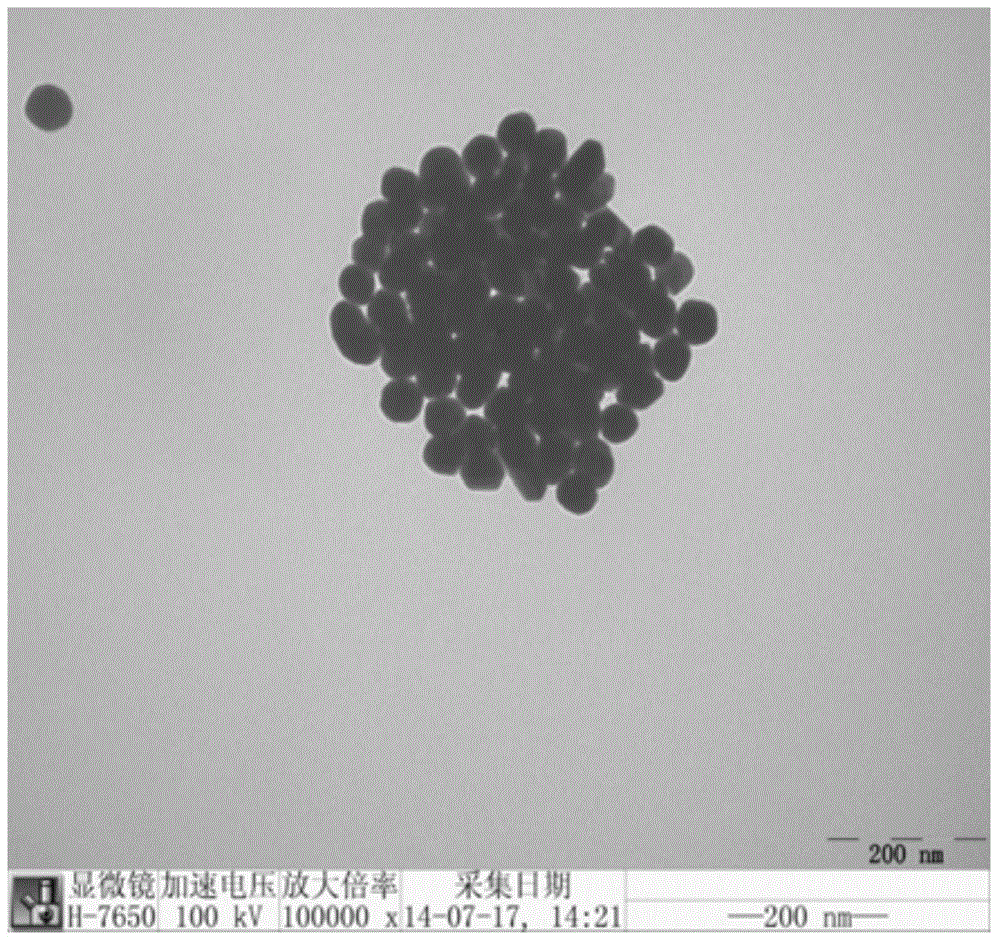

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: This embodiment is a seed crystal growth method for preparing gold nanoparticles, which is specifically carried out in the following steps:

[0016] 1. Preparation of gold species: HAuCl with a mass fraction of 1% 4 The aqueous solution is added to deionized water, and the temperature is raised from room temperature to 99°C under the condition of a rotating speed of 250rpm. 600rpm ~ 1200rpm and a temperature of 99 ° C under the conditions of reaction for 15min ~ 20min, stop stirring and heating, and naturally cool to room temperature to obtain a small particle size spherical gold nanoparticle solution; the mass fraction is 1% HAuCl 4 The volume ratio of aqueous solution to deionized water is 1:(90~100); the mass fraction is 1% HAuCl 4 Aqueous solution and mass fraction are that the volume ratio of the sodium citrate aqueous solution of 1% is 1:(3~5);

[0017] 2. Preparation of gold nanoparticles by seed crystal growth method: HAuCl with a mass fraction o...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the mass fraction is 1% HAuCl 4 The aqueous solution is added to deionized water, and the temperature is raised from room temperature to 99°C under the condition of 250rpm at the rotating speed, and then 1% sodium citrate aqueous solution is added with the mass fraction under the condition of 1000rpm and 99°C at the rotating speed. After reacting for 15 minutes at a temperature of 99° C., stop stirring and heating, and naturally cool to room temperature to obtain a small-diameter spherical gold nanoparticle solution. Others are the same as in Embodiment 1.

specific Embodiment approach 3

[0023] Specific embodiment three: this embodiment is different from one of specific embodiments one to two: the mass fraction described in step one is 1% HAuCl 4 The volume ratio of aqueous solution to deionized water is 1:100. Others are the same as one of the specific embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com