Device for rapidly responding to required ammonia amount changes in urea-hydrolysis ammonia preparation and implementation method of device

A urea hydrolysis and rapid response technology, which can be used in the simultaneous control of multiple variables, non-electric variable control, ammonia preparation/separation, etc., can solve the problems of slow response speed of urea hydrolysis to ammonia production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

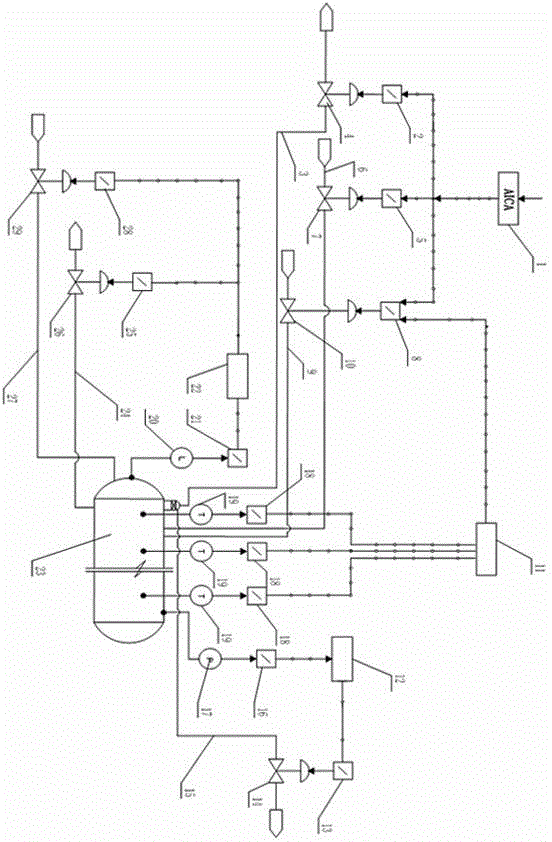

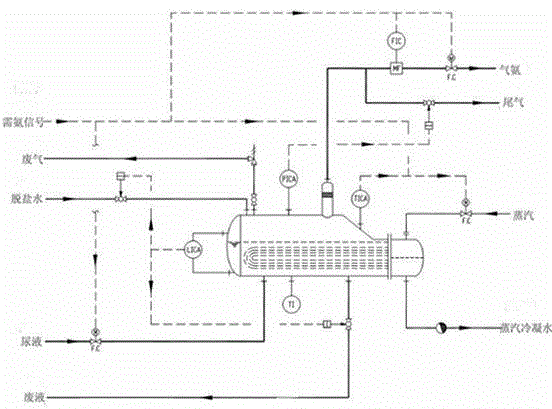

[0073] Such as figure 1 and figure 2 As shown, the urea hydrolysis ammonia production quick response ammonia demand change device includes a hydrolyzer 23, a urine input pipe 6, a gas ammonia output pipe 3, a gas ammonia flow control valve 4 arranged on the gas ammonia output pipe, and a gas ammonia flow control valve 4 arranged on the urine ammonia output pipe. The urine flow control valve 7 on the liquid input pipe, the signal analysis display alarm controller 1 for receiving and processing the ammonia demand signal, the first signal converter 2 and the second signal converter 5, one end of the urine input pipe 6 One end of the gas and ammonia output pipe 3 is all communicated with the hydrolyzer 23, and the signal analysis shows that the signal output end of the alarm controller 1 is respectively connected with the signal input end of the first signal converter 2 and the signal input of the second signal converter 5 through the signal line. The signal output end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com