Up-flow sequencing batch bioreactor technology

A sequencing batch biological and reactor technology, applied in the field of removing organic pollutants, nitrogen and phosphorus, to achieve the effect of improving container utilization, increasing sludge concentration and volume load, and reducing inefficient space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

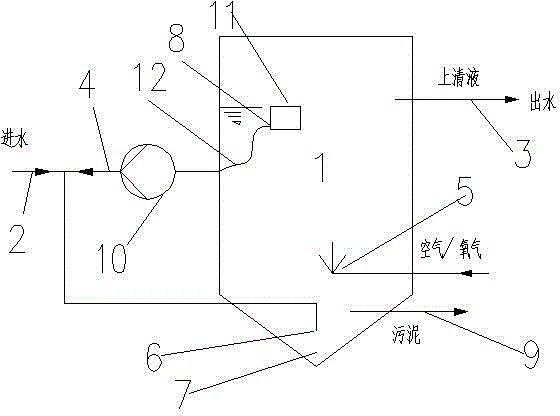

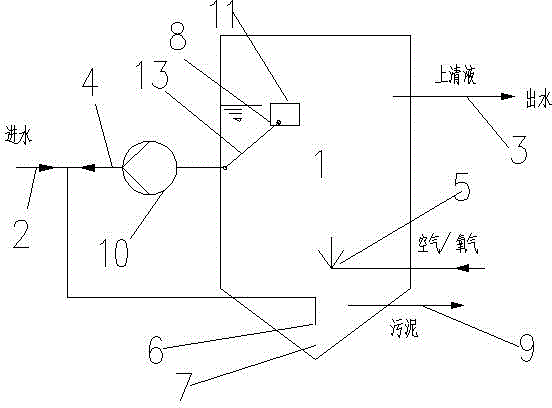

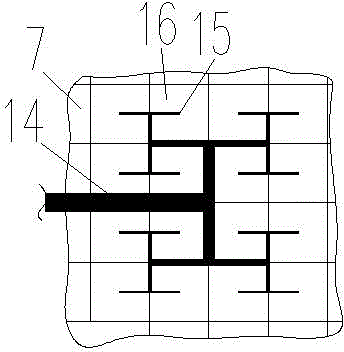

[0016] exist figure 1 Among them, the upper reflux device (8), circulation pump (10) and circulation pipeline (4) of the upward flow sequence batch bioreactor (1) are connected to the upward A bottom water distribution device (6) at the bottom of the reactor (7) of the sequential batch bioreactor (1). One or more of the three agitation forms of the rising liquid flow formed by the water inlet in different reaction stages, the rising liquid flow formed by the reflux of the upper liquid, and the upward channeling bubbles formed by the gas supply of the sequencing batch bioreactor oxygenation device (5) It can play the role of hydraulic stirring and important classification for the sludge particles in the reaction zone, and then affect the process of sludge granulation. The supernatant after fully reacting in the upward flow sequencing batch bioreactor (1) is discharged through the outlet pipe (3), and the sludge is discharged through the sludge discharge pipe (9) of the sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com