Composite corrosion-inhibiting and antisludging agent composition and preparation method thereof

A technology of corrosion and scale inhibitors and compositions, which is applied in the field of preparation of composite corrosion and scale inhibitors, can solve the problems of low corrosion and scale inhibition performance, and achieve the effect of improving corrosion and scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example is used to illustrate the composite corrosion and scale inhibitor composition of the present invention and its preparation method.

[0051] (1) Preparation of the first mixture (heteropoly acid)

[0052] Mix 10 g of water and 0.2 g of sodium phosphate, stir at room temperature until fully dissolved, then add 1 g of phosphoric acid and continue stirring until dissolved, then add 1 g of sulfuric acid, and stir at room temperature for 30 minutes to obtain the first mixture.

[0053] (2) Prepare the second mixture

[0054] 0.2 g of HPAA and 1 g of perchloric acid were mixed and stirred at room temperature for 30 minutes to obtain a second mixture.

[0055] (3) Prepare the third mixture

[0056] 51.6g of water, 20g of polyepoxysuccinic acid, 5g of acrylic acid and 2-acrylamido-2-methyl-propanesulfonic acid copolymer and 10g of zinc chloride were mixed and stirred at room temperature until fully dissolved to obtain the third mixture.

[0057] (4) Preparation ...

Embodiment 2-6

[0060] This example is used to illustrate the composite corrosion and scale inhibitor composition of the present invention and its preparation method.

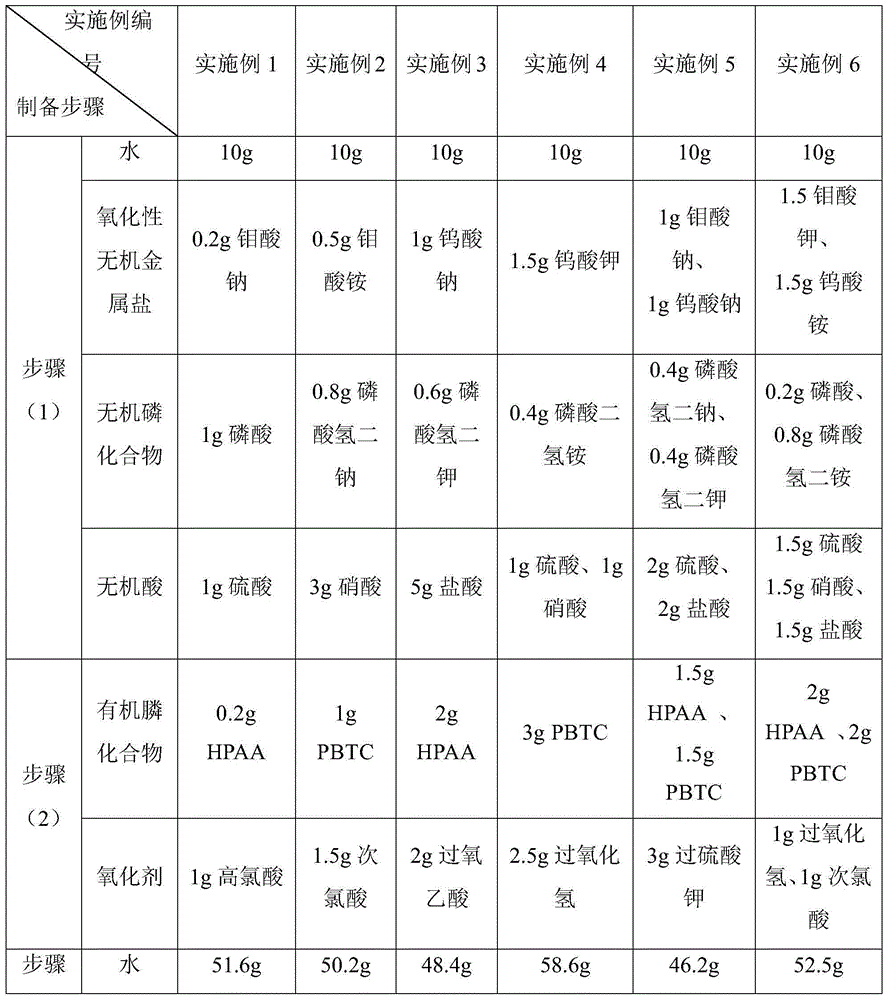

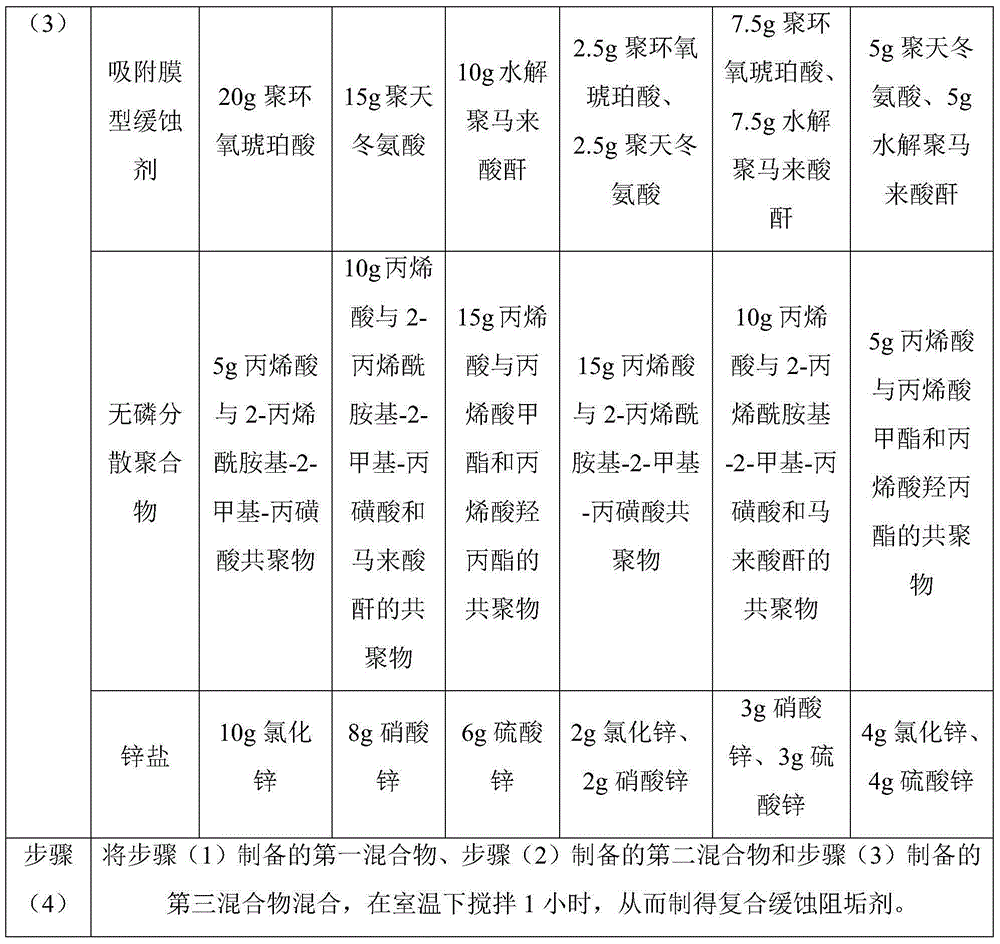

[0061] Composite corrosion and scale inhibitors were prepared according to the method of Example 1, except that the types and amounts of materials in each step were as shown in Table 1, so that composite corrosion and scale inhibitors A2-A6 were prepared respectively.

[0062] Table 1

[0063]

[0064]

Embodiment 7

[0078] This example is used to illustrate the composite corrosion and scale inhibitor composition of the present invention and its preparation method.

[0079] The types of materials used in this embodiment and the amount of feed are the same as those in Example 1. The difference is that the various materials are not mixed step by step, but are mixed directly. The specific preparation process is: directly mix 61.6g of water, 0.2 g sodium phosphate, 1 g phosphoric acid, 1 g sulfuric acid, 0.2 g HPAA, 1 g perchloric acid, 20 g polyepoxysuccinic acid, 5 g acrylic acid and 2-acrylamido-2-methyl-propanesulfonic acid copolymer and 10 g chloride Zinc is mixed and stirred at room temperature until it is fully dissolved, thereby preparing composite corrosion and scale inhibitor A7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com