A kind of concrete protective sol

A technology of concrete and sol, which is applied in the field of concrete protective materials, can solve problems such as difficulty in realizing concrete protection function, environmental temperature and humidity, heavy load wear, and poor development of concrete strength, so as to improve self-leveling performance, solve cracking, and improve gap tightness The effect of low solidity

Active Publication Date: 2016-05-18

徐州加贝力建材科技有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Usually concrete is composed of granular coarse aggregate, fine aggregate and cement hydrate. During the pouring process and use, due to various reasons, some quality problems often occur and affect its service life.

In the process of pouring and curing, due to cement hydration and water evaporation, it is easy to cause concrete cracking, resulting in poor concrete strength development

Moreover, in the application of concrete in actual engineering, it is often exposed to various harsh environments, such as the intrusion of corrosive media around the environment, changes in environmental temperature and humidity, freeze-thaw cycle damage, and some concrete projects are often subject to heavy load wear. External conditions will seriously affect the service life of concrete

Therefore, the use of a simple concrete curing agent is difficult to achieve the concrete protection function during pouring.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

[0027] Example 3 is the best implementation.

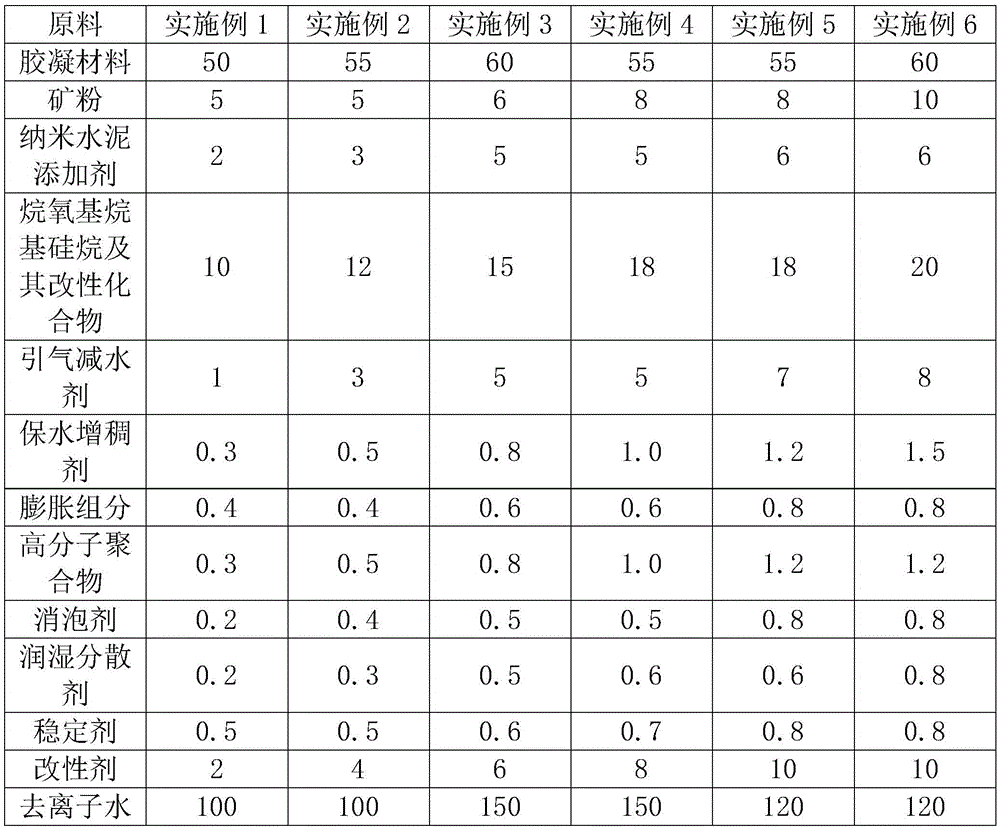

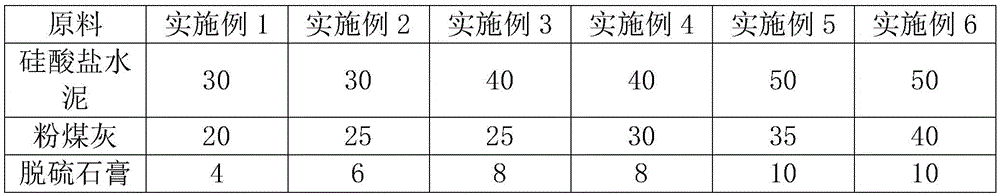

[0028] The mass parts composition of the gelling materials in Examples 1-6 are shown in Table 2.

[0029]

[0030] Example 3 is the best implementation.

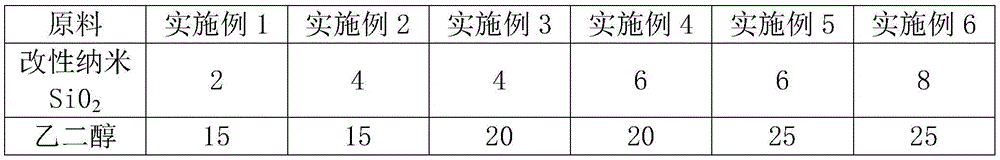

[0031] The mass composition of the nano cement additives in Examples 1-6 are shown in Table 3.

[0032]

[0033] Example 3 is the best implementation.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of concrete protective materials and in particular relates to concrete protecting sol. The concrete protecting sol comprises the following components in parts by mass: 50-60 parts of a cementitious material, 5-10 parts of mineral powder, 2-6 parts of a nano cement additive, 10-20 parts of alkoxyl alkylsilane and a modified compound thereof, 1-8 parts of an air-leading and water-reducing agent, 0.3-1.2 parts of a water-retaining and thickening agent, 0.4-0.8 part of an expansion component, 0.3-1.2 parts of a macromolecular polymer, 0.2-0.8 part of a defoaming agent, 0.2-0.8 part of a wetting-dispersing agent, 0.5-0.8 part of a stabilizing agent, 2-10 parts of a modifying agent and 100-150 parts of deionized water. The concrete protecting sol has the beneficial effects that due to mixed use of the nano cement additive, alkoxyl alkylsilane and the modified compound thereof and the air-leading and water-reducing agent, the defect that gap compacting degree of concrete is low is overcome, and the penetrating agent alkoxyl alkysilane and the modified compound thereof can permeate into the concrete, a concrete structure is improved, and the defects that the concrete is cracked, strength is low and service life is short are fundamentally overcome.

Description

Technical field [0001] The invention relates to the technical field of concrete protective materials, in particular to a concrete protective sol. Background technique [0002] The scale of infrastructure investment in cement concrete construction in my country is huge, the maintenance cost is quite high, and the demand for repair materials is also very large. At present, the protection of concrete structures mostly adopts the method of coating the outer surface of concrete with protective materials. Among the permeable materials, such as materials with sodium silicate as the main component, they are coated or injected with silicon on the waterproof and repair parts. A material with sodium as the main component to protect the concrete structure. However, this material has problems such as rapid reaction speed in concrete caused by the main sodium monosilicate, poor permeability, and easily abraded and damaged surface membranes. [0003] The protection of concrete should be protect...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/14C04B41/50C04B24/42

Inventor 陈吉美

Owner 徐州加贝力建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com