Concrete protective sol

A technology of concrete and sol, which is applied in the field of concrete protective materials, can solve the problems of affecting the service life of concrete, poor concrete strength development, and affecting service life, so as to improve the low compactness of voids, improve self-leveling performance, and save construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

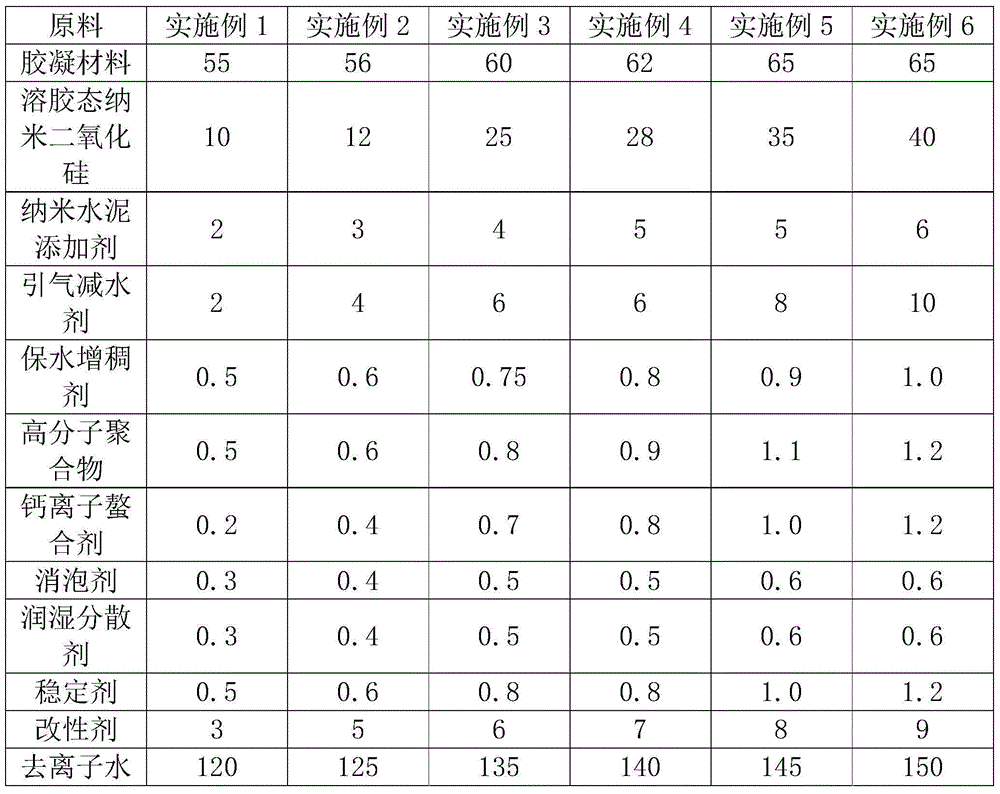

Examples

Embodiment 3

[0027] Embodiment 3 is the best implementation mode.

[0028] See Table 2 for the compositions in parts by mass of the gelling material in Examples 1-6.

[0029] raw material Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 plaster 10 20 40 50 60 80 Inorganic gel 20 25 30 40 50 60 Activated carbon powder 10 12 16 18 18 20 industrial soda ash 8 10 12 15 18 20

[0030] Embodiment 3 is the best implementation mode.

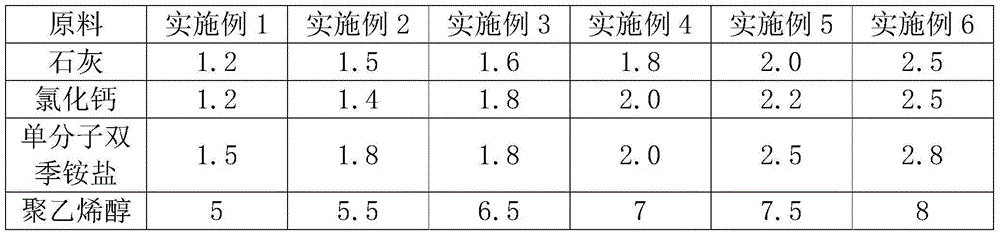

[0031] See Table 3 for the composition by mass of nano-cement additives in Examples 1-6.

[0032]

[0033] Embodiment 3 is the best implementation mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com