Method for purifying pomalidomide

A purification method, the technology of polilidomide, which is applied in the direction of organic chemistry, can solve the problem of insufficient purity of polilidomide, and achieve the effects of environmental friendliness, high yield and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

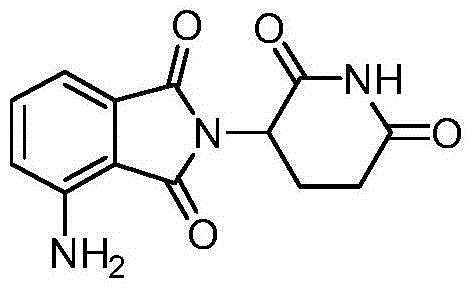

Image

Examples

Embodiment 1

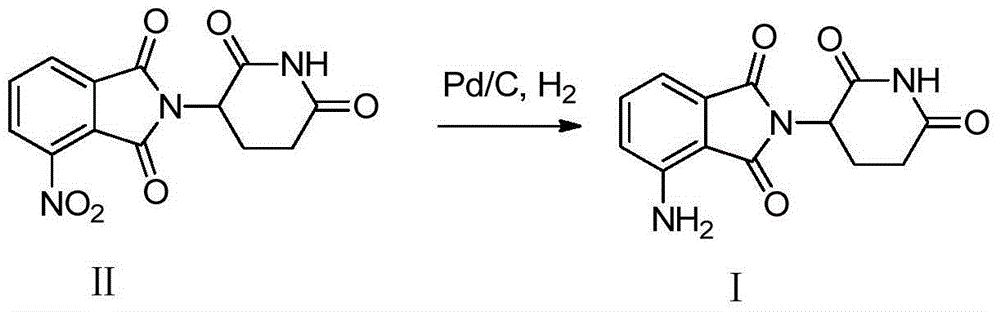

[0032] The preparation of embodiment 1 polilidomide crude product

[0033] Mix 5 g of 1,3-dioxo-2-(2,6-dioxopiperidin-3-yl)-5-nitroisoindoline and 0.4 g of 10% palladium carbon into 70 mL of N,N - in dimethylacetamide, then carry out hydrogenation reaction at 0.4Mpa, the reaction temperature is 30°C, last 6 hours, filter the catalyst, concentrate the filtrate in vacuo, beat the residue with 40mL water at 40°C overnight, and obtain 3.7g Crude polilidomide as a yellow-green solid. The purity measured by HPLC was 99.0%.

Embodiment 2

[0034] The preparation of embodiment 2 polilidomide crude product

[0035] Mix 5 g of 1,3-dioxo-2-(2,6-dioxopiperidin-3-yl)-5-nitroisoindoline and 0.1 g of 5% palladium carbon into 70 mL of N,N - in dimethylacetamide, then carry out hydrogenation reaction at 0.4Mpa, the reaction temperature is 40°C, last 6 hours, filter the catalyst, concentrate the filtrate in vacuo, beat the residue with 40mL water at 40°C overnight, and obtain 3.7g Crude polilidomide as a yellow-green solid. The purity by HPLC was 95.3%.

Embodiment 3

[0036] The purification of embodiment 3 polilidomide crude product

[0037] Add 1 g of the crude polilidomide in Example 1 to 30 mL of a mixed solvent of N,N-dimethylacetamide and water (the volume ratio of N,N-dimethylacetamide and water is 4:1) and 0.08g of activated carbon, heated to 60°C to dissolve for 1h to 2h, filtered while hot, cooled the filtrate to -10°C, crystallized for 12h, filtered with suction, washed the filter cake with 15mL of water, dried overnight at 40°C to obtain 0.7g poly Pure Methamide. The purity by HPLC was 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com