Water-based water-scrubbing-resistant acrylic emulsion and preparation method thereof

An acrylic emulsion and acrylic technology, applied in the coating and other directions, can solve the problems of the coating being easily scratched, the production is unsafe, the environmental protection and hygiene are poor, etc., and the effect of improving the water scrub resistance, low cost and low VOC of the emulsion can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

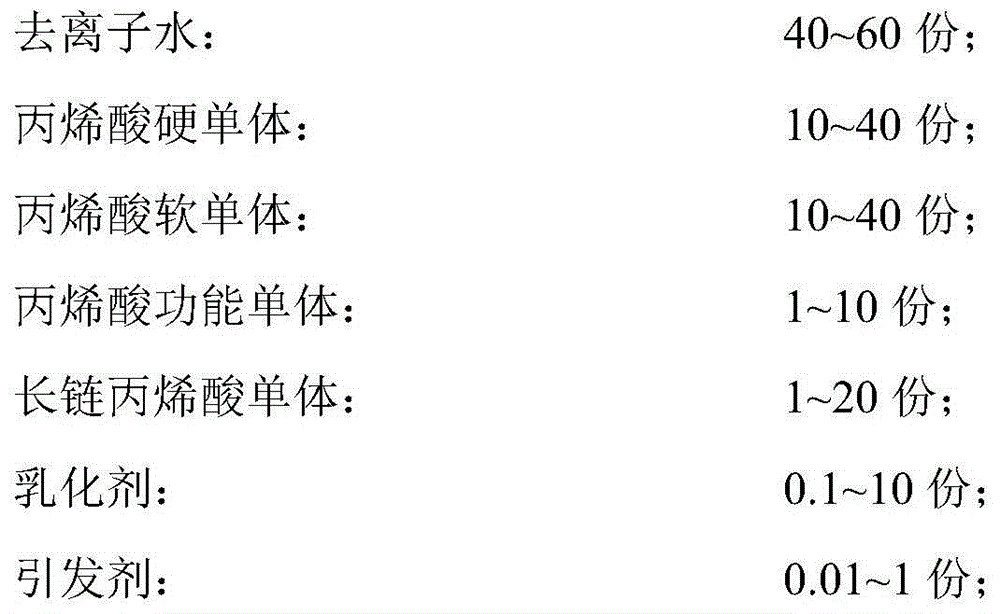

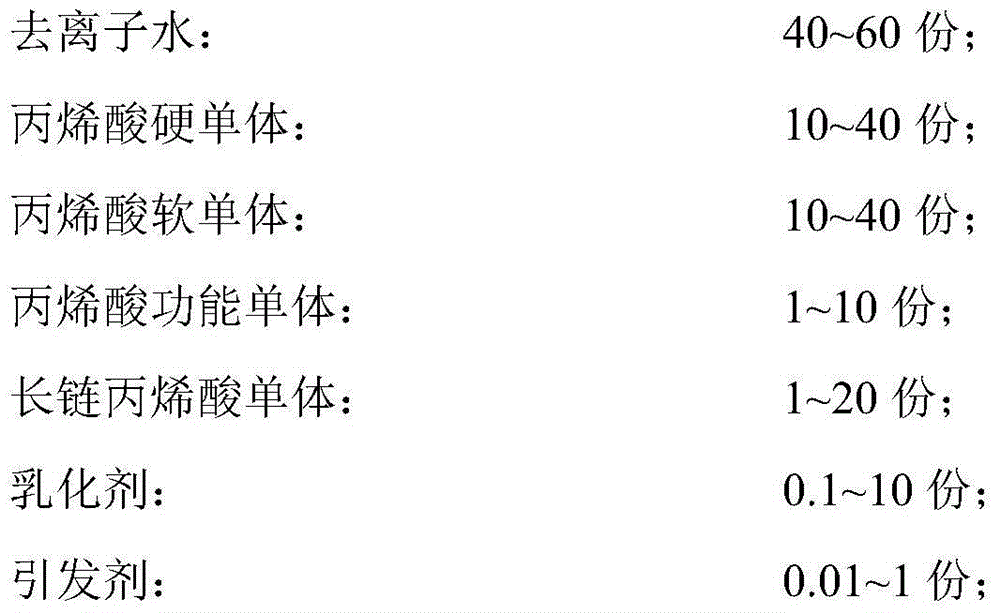

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation method of water-based anti-water scrubbing acrylic emulsion that the present embodiment relates to, comprises the steps:

[0024] 1. Add 15 parts of deionized water, 2 parts of emulsifier, 1 part of methacrylic acid, 17 parts of butyl acrylate, 15 parts of methyl methacrylate, 10 parts of octadecyl acrylate, and 2 parts of hydroxyethyl acrylate into In the mixing tank, stir for more than 30 minutes to obtain the pre-emulsion, and set aside;

[0025] 2. Add 31 parts of deionized water into the reaction kettle, raise the temperature, and control the temperature at 78-82 ° C; add 0.1 parts of potassium persulfate and 5 parts of the prepared pre-emulsion, and keep it warm for 30 minutes after the emulsion turns blue. Add the remaining pre-emulsion and the initiator solution prepared by 0.9 parts of potassium persulfate and 5 parts of deionized water dropwise, and control the addition of the pre-emulsion and the initiator solution within 2 to 5 hours. A...

Embodiment 2

[0028] A kind of preparation method of water-based anti-water scrubbing acrylic emulsion that the present embodiment relates to, comprises the steps:

[0029] 1. Mix 15 parts of deionized water, 0.1 part of emulsifier, 9 parts of methacrylic acid, 10 parts of ethyl acrylate, 10 parts of methyl methacrylate, 20 parts of octadecyl methacrylate, 1 part of hydroxyethyl acrylate, Add to the mixing tank and stir for more than 30 minutes to prepare the pre-emulsion, set aside;

[0030] 2. Add 24 parts of deionized water into the reaction kettle, raise the temperature, and control the temperature at 78-82°C. Add 0.001 part of ammonium persulfate and 6 parts of the prepared pre-emulsion. After the emulsion turns blue, keep warm for 30 minutes. At the same time, drop the remaining pre-emulsion and the initiator solution prepared by 0.009 part of potassium persulfate and 5 parts of deionized water. , control the dropwise addition of the pre-emulsion and the initiator solution within 2 t...

Embodiment 3

[0033] A kind of preparation method of water-based anti-water scrubbing acrylic emulsion that the present embodiment relates to, comprises the steps:

[0034] 1. Mix 30 parts of deionized water, 10 parts of emulsifier, 0.5 parts of methacrylic acid, 40 parts of isooctyl acrylate, 10 parts of methyl methacrylate, 1 part of lauryl methacrylate, and 0.5 parts of hydroxypropyl acrylate , added to the mixing tank and stirred for more than 30 minutes to prepare the pre-emulsion, set aside;

[0035] 2. Add 20 parts of deionized water into the reaction kettle, raise the temperature, and control the temperature at 78-82°C; add 0.02 parts of potassium persulfate and 5 parts of the prepared pre-emulsion, and keep it warm for 30 minutes after the emulsion turns blue. Add the remaining pre-emulsion and the initiator solution prepared by 0.08 parts of potassium persulfate and 10 parts of deionized water dropwise, and control the addition of the pre-emulsion and the initiator solution within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com