Polypropylene composition for ampoule bottle

A polypropylene composition and polypropylene technology, which are applied to special packaging items, packaging item types, medical containers, etc., can solve the problems such as the material properties and preparation methods of ampoules that are not mentioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

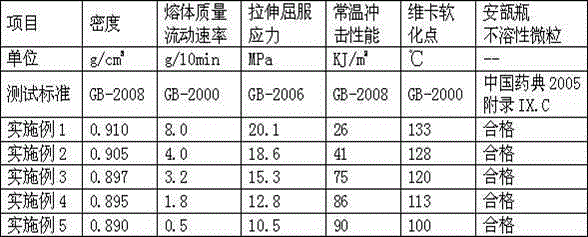

Examples

Embodiment 1

[0020] Random copolymerized polypropylene: 95 parts

[0021] It contains 3% ethylene by mass, and has a melt mass flow rate (MFR) of 2.5g / 10min at 230°C and 2.16kg.

[0022] SEBS: 5 servings

[0023] Containing 13% styrene by mass, the melt mass flow rate (MFR) is 3.0g / 10min under the conditions of 230°C and 2.16kg, G1645, KRATON Polymer Company of the United States.

[0024] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester: 0.025 parts

[0025] Tris(2,4-di-tert-butyl)phenyl phosphite: 0.025 parts

[0026] Mix the random copolymerized polypropylene, elastomer SEBS, and antioxidant in a high-speed mixer in proportion to the above composition, then add them to a twin-screw extruder for melting and mixing, and extrude to granulate. Extrusion temperature: 180°C-230°C, screw speed: 200rpm.

Embodiment 2

[0028] Random copolymerized polypropylene: 85 parts

[0029] SEBS: 10 servings

[0030] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester: 0.05 parts

[0031] Bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite: 0.1 parts

[0032] Mix the random copolymerized polypropylene, elastomer SEBS, and antioxidant in a high-speed mixer in proportion to the above composition, then add them to a twin-screw extruder for melting and mixing, and extrude to granulate. Extrusion temperature: 180°C-230°C, screw speed: 150rpm.

Embodiment 3

[0034] Random copolymerized polypropylene: 80 parts

[0035] SEBS: 20 servings

[0036] n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate: 0.05 parts

[0037] Tris(2,4-di-tert-butyl)phenyl phosphite: 0.1 parts

[0038] Mix the random copolymerized polypropylene, elastomer SEBS, and antioxidant in a high-speed mixer in proportion to the above composition, then add them to a twin-screw extruder for melting and mixing, and extrude to granulate. Extrusion temperature: 180°C-230°C, screw speed: 300rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt mass flow rate | aaaaa | aaaaa |

| Melt mass flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com