Low-temperature-brittleness-resistant PVC pipe material and preparation method thereof

A PVC pipe, low temperature resistance technology, applied in the field of plastic products, can solve the problems of control, high production cost, difficult production process, etc., and achieve the effects of easy processing, improved low temperature brittleness, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

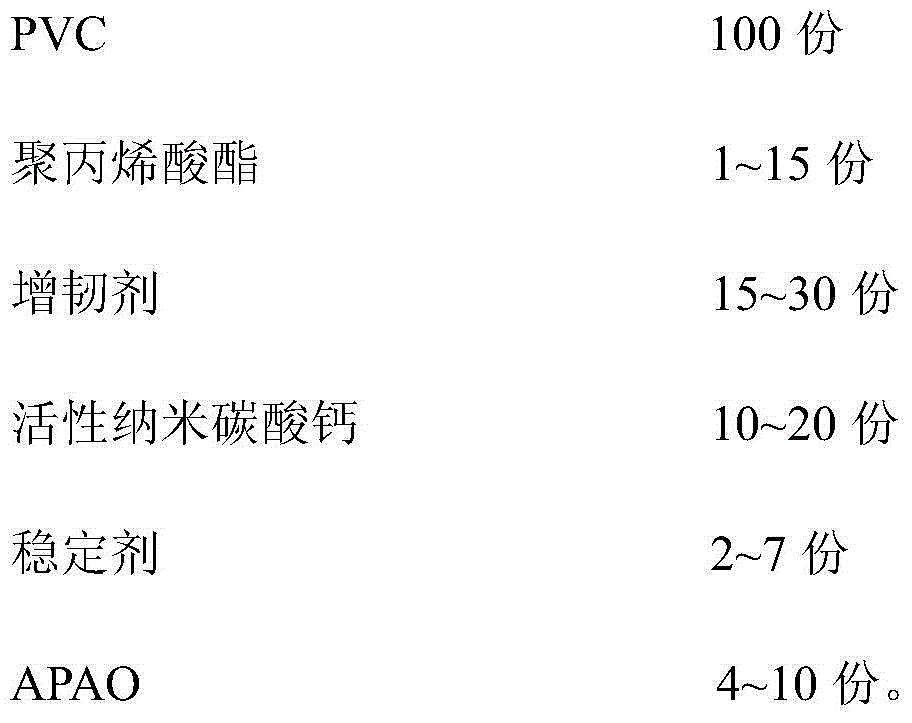

Method used

Image

Examples

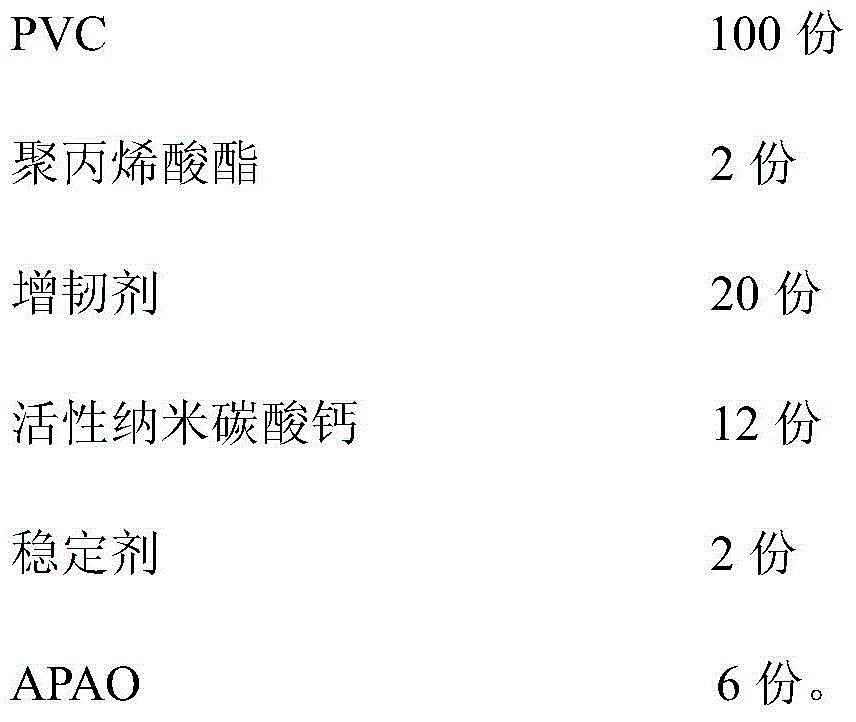

Embodiment 1

[0027]

[0028] Wherein, the toughening agent is dioctyl phthalate; the APAO has moderate molecular weight, good elasticity, certain fluidity and wettability, which can improve the processability of the PVC mixed system and improve the cold resistance at low temperature. The number average molecular weight is 09,000 to 13,000;

[0029] 1) According to the parts by weight of each raw material component, PVC, polyacrylate, toughening agent, active nano-calcium carbonate, stabilizer and APAO are mixed at high speed;

[0030] 2) The material is cooled to 40-50°C by a cold mixer;

[0031] 3) Extrude into powder with a twin-screw extruder, and the extrusion temperature of the twin-screw extruder is 110-120°C.

[0032] PVC pipes are obtained after vacuum calibrating box and pipe traction cutting. Test the impact resistance at 0°C according to GB / T 14152, and measure the embrittlement temperature by impact method according to GB / T5470-2008.

Embodiment 2

[0034]

[0035] Wherein, the toughening agent is dioctyl phthalate; the APAO has moderate molecular weight, good elasticity, certain fluidity and wettability, which can improve the processability of the PVC mixed system and improve the cold resistance at low temperature. The number average molecular weight is 14,000 to 20,000;

[0036] 1) According to the parts by weight of each raw material component, PVC, polyacrylate, toughening agent, active nano-calcium carbonate, stabilizer and APAO are mixed at high speed;

[0037] 2) The material is cooled to 40-50°C by a cold mixer;

[0038] 3) Extrude into powder with a twin-screw extruder, and the extrusion temperature of the twin-screw extruder is 110-120°C.

[0039] PVC pipes are obtained after vacuum calibrating box and pipe traction cutting. Test the impact resistance at 0°C according to GB / T 14152, and measure the embrittlement temperature by impact method according to GB / T5470-2008.

Embodiment 3

[0041]

[0042] Wherein, the toughening agent is dioctyl phthalate; the APAO has moderate molecular weight, good elasticity, certain fluidity and wettability, which can improve the processability of the PVC mixed system and improve the cold resistance at low temperature. The number average molecular weight is 15,000 to 18,000;

[0043] 1) According to the parts by weight of each raw material component, PVC, polyacrylate, toughening agent, active nano-calcium carbonate, stabilizer and APAO are mixed at high speed;

[0044] 2) The material is cooled to 40-50°C by a cold mixer;

[0045] 3) Extrude into powder with a twin-screw extruder, and the extrusion temperature of the twin-screw extruder is 110-120°C.

[0046] PVC pipes are obtained after vacuum calibrating box and pipe traction cutting.

[0047] Specifically, in Examples 1 to 3, after cooling and shaping in a vacuum qualitative box of 0.05 MPa, PVC pipes were drawn and cut at a speed of 4 m / min.

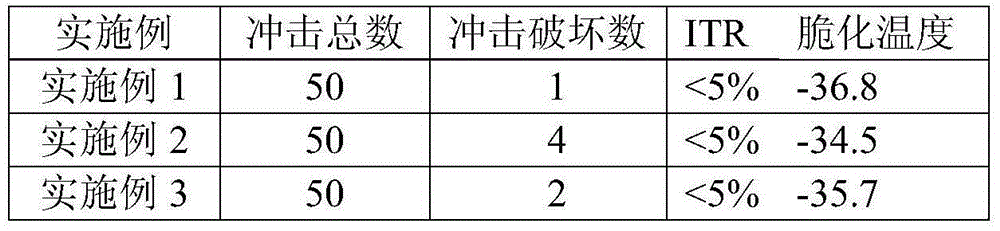

[0048] Test the impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com