Low-temperature hot melt adhesive

A technology of low-temperature heat and melting adhesives, which is applied in the direction of adhesives, adhesive types, and mineral oil hydrocarbon copolymer adhesives. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

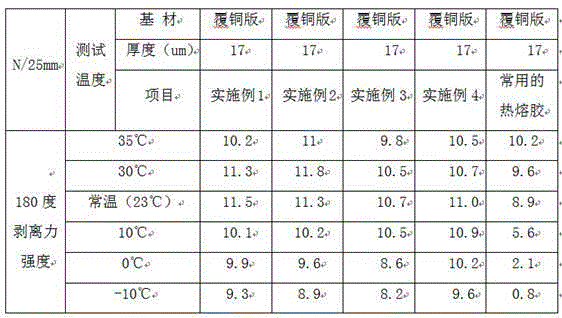

Examples

Embodiment 1

[0023] The mass ratio components of the low temperature hot melt adhesive are as follows:

[0024] Styrene-isoprene-styrene block copolymer (SIS) 10g,

[0025] C5 petroleum resin 12g,

[0026] Powdered nitrile rubber (acrylonitrile content; 32-35%) 9g,

[0027] GA-90 rosin resin 20g,

[0028] KN4010 naphthenic oil 20g,

[0029] Honeywell Polyethylene Wax AC8 10g,

[0030] Antioxidant B225 0.8g.

[0031] According to a low-temperature hot melt of the above formula, the preparation method is as follows:

[0032] 1) Styrene-isoprene-styrene block copolymer (SIS) with fixed components and KN4010 naphthenic oil were oil-extended at 90°C for 20 minutes.

[0033] 2) Add antioxidant B225 and stir at high speed at 180°C.

[0034] 3) Add petroleum resin, powdered nitrile rubber, rosin resin, Honeywell polyethylene wax AC8 in sequence and keep stirring and kneading.

[0035] 4) Extrude the hot melt adhesive that has been stirred and kneaded evenly through the extruder. The follo...

Embodiment 2

[0037] Low-temperature hot-melt adhesive, including the mass ratio of the following ingredients mixed uniformly:

[0038] Styrene-isoprene-styrene block copolymer (SIS) 40g,

[0039] C5 petroleum resin 28g,

[0040] KN4010 naphthenic oil 25g,

[0041] Honeywell Polyethylene Wax AC8 21g,

[0042] GA-90 Rosin Resin 18g,

[0043] Powdered nitrile rubber 16g,

[0044] Antioxidant B225 0.5g.

Embodiment 3

[0046] Low-temperature hot-melt adhesive, including the following mass ratios mixed uniformly:

[0047] Styrene-isoprene-styrene block copolymer (SIS) 26g,

[0048] C5 petroleum resin 15g,

[0049] Antioxidant B225 5g,

[0050] Honeywell Polyethylene Wax AC8 40g,

[0051] GA-90 Rosin Resin 16g,

[0052] Powdered nitrile rubber 16g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com