Anti-explosion gasoline cleansing agent

A detergent and gasoline technology, which is used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problem of particulate matter emission, and achieve the effect of improving octane number and good environmental compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

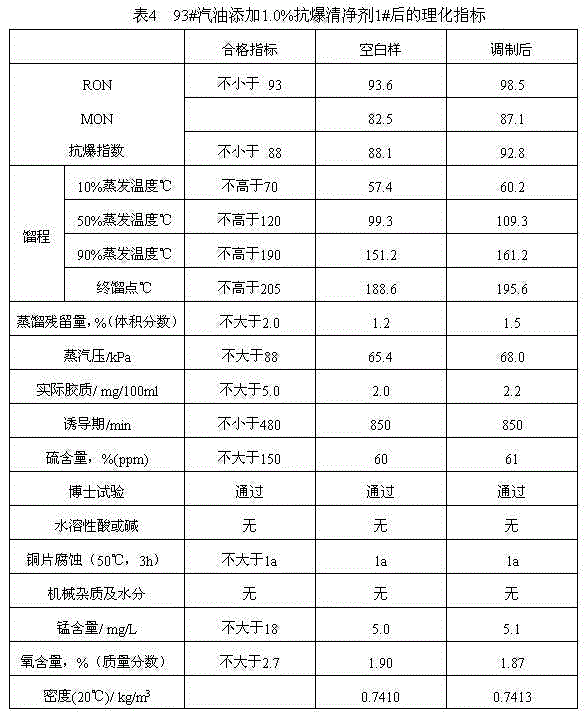

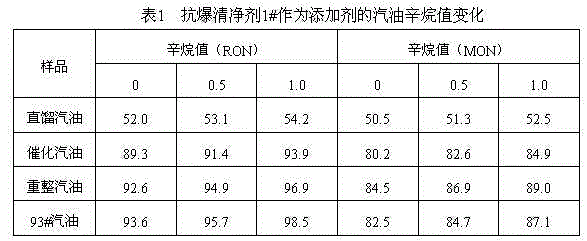

Examples

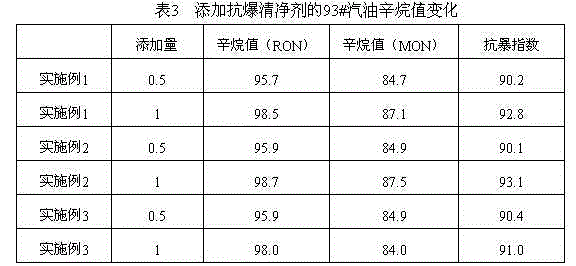

Embodiment 1

[0013] Add 16.2mL of methanol, 30mL of 85% sulfuric acid, 20.3mL of tert-butanol, and 20.3mL of n-pentanol into a three-necked flask equipped with a thermometer and a condenser, raise the temperature to 50°C and stir for 2.2h, then distill at elevated temperature and collect 46-120 The fraction between ℃ was dried with anhydrous magnesium sulfate to obtain 48.3 mL of methyl n-amyl ether / methyl tert-butyl ether mixture.

[0014] Mix the above mixed solution with dimethylaniline at a volume ratio of 1:1 to obtain antiknock detergent 1#.

Embodiment 2

[0016] Add 38.9mL of methanol, 60mL of 85% sulfuric acid, 40.6mL of tert-butanol, and 40.6mL of n-pentanol into a three-necked flask equipped with a thermometer and a condenser, raise the temperature to 52°C and stir for 2.5h, heat up and distill, and collect 48-120 The fraction between ℃ was dried with anhydrous magnesium sulfate to obtain 98.5 mL of methyl n-amyl ether / methyl tert-butyl ether mixed solution.

[0017] Mix the above mixture with dimethylaniline at a volume ratio of 1:1 to obtain antiknock detergent 2#.

Embodiment 3

[0019] Add 97.2mL of methanol, 90mL of 85% sulfuric acid, 81.2mL of tert-butanol, and 81.2mL of n-pentanol into a three-necked flask equipped with a thermometer and a condenser, raise the temperature to 55°C and stir for 3 hours, heat up and distill, and collect 48-122°C The fractions in between were dried with anhydrous magnesium sulfate to obtain 215.1 mL of methyl n-amyl ether / methyl tert-butyl ether mixture.

[0020] Mix the above mixed solution with dimethylaniline at a volume ratio of 1:1 to obtain antiknock detergent 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com