Preparation method for monofilaments containing hemp meal

A technology of hemp flour and monofilament, which is applied in the directions of melt spinning, manufacturing tools, conjugated synthetic polymer man-made filaments, etc., can solve problems such as poor surface bonding performance, and achieve the effect of shortening the production process and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

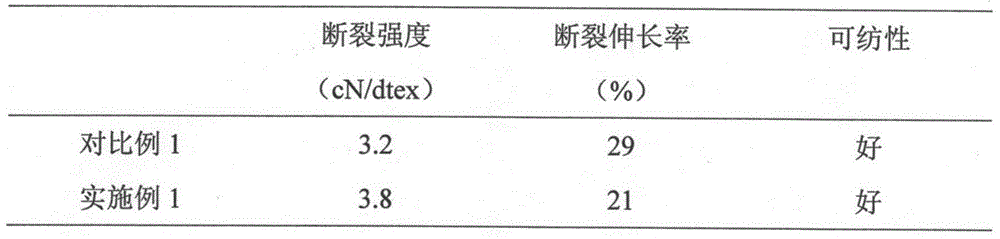

Embodiment 1

[0019] The preparation method of adding hemp powder to PP filaments is as follows:

[0020] After the hemp skin and the hemp stalk are pulverized in an ultrafine pulverizer, the hemp powder with a particle diameter of 10 to 60 microns is ground through a ball mill, and the hemp skin and hemp stalk are mixed evenly with a mass ratio of 1:1 to obtain the hemp powder. The powder will be treated with a silane coupling agent with a mass fraction of 1%. The mass of the silane coupling agent solute accounts for 1% of the mass of the hemp powder, and then it is baked in an oven at 100°C for 8 hours. After the hemp powder is dried, take the processed Afterwards, 0.09 g of hemp powder and 2.91 g of PP were melt-spun, the temperature of the twin-screw extruder was 190° C., the temperature of the spinning die was 230° C., and the spinning speed was 350 m / min. After winding and forming by a winding machine, the stretching speed is 80 m / min, and then the spun filaments are stretched twice b...

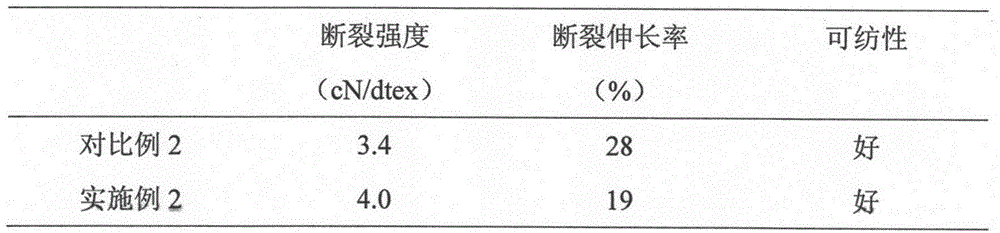

Embodiment 2

[0026] The preparation method of adding hemp powder to PP filaments is as follows:

[0027] After the hemp skin and the hemp stalk are pulverized in an ultrafine pulverizer respectively, the hemp powder with a particle diameter of 10 to 60 microns is ground through a ball mill, and the hemp skin and hemp stalk are mixed evenly with a mass ratio of 1:2 to obtain the hemp powder. The powder will be treated with a silane coupling agent with a mass fraction of 1%. The mass of the silane coupling agent solute accounts for 1% of the mass of the hemp powder, and then it is baked in an oven at 100°C for 8 hours. After the hemp powder is dried, take the processed Afterwards, 0.09 g of hemp powder and 2.91 g of PP were melt-spun, the temperature of the twin-screw extruder was 190° C., the temperature of the spinning die was 230° C., and the spinning speed was 350 m / min. After winding and forming by a winding machine, the stretching speed is 80 m / min, and then the spun filaments are stre...

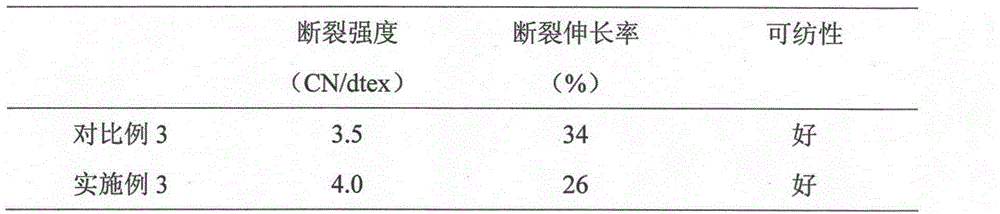

Embodiment 3

[0033] The preparation method of adding hemp powder to PP filaments is as follows:

[0034] After the hemp skin and the hemp stalk are pulverized in an ultrafine pulverizer respectively, the hemp powder with a particle diameter of 10 to 60 microns is ground through a ball mill, and the hemp skin and hemp stalk are mixed evenly with a mass ratio of 2:3 to obtain the hemp powder. The powder will be treated with a silane coupling agent with a mass fraction of 1%. The mass of the silane coupling agent solute accounts for 3% of the mass of the hemp powder, and then baked in an oven at 100°C for 8 hours. After the hemp powder is dried, take the processed Afterwards, 0.18 g of hemp powder and 2.82 g of PP were melt-spun, the temperature of the twin-screw extruder was 220° C., the temperature of the spinning die was 240° C., and the spinning speed was 750 m / min. After winding and forming by a winding machine, the stretching speed is 180 m / min, and then the spun silk is stretched twice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com