Velvet fabric blank, velvet fabric and preparing method of velvet fabric

A technology of fabric and velvet feeling, which is applied in the processing of fabrics and textile materials, and the continuous processing of textile materials, etc. It can solve the problems of low strength and weak velvet feeling of velvet fabrics, and achieve good velvet feel, good hand feeling and strong strength. less loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

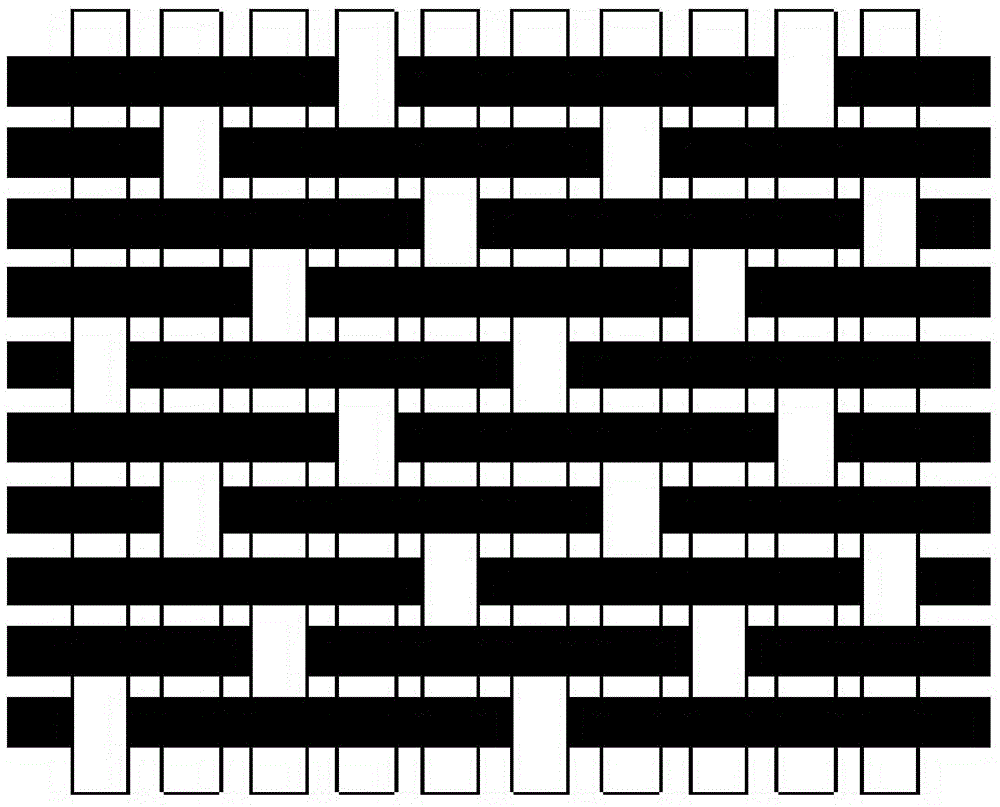

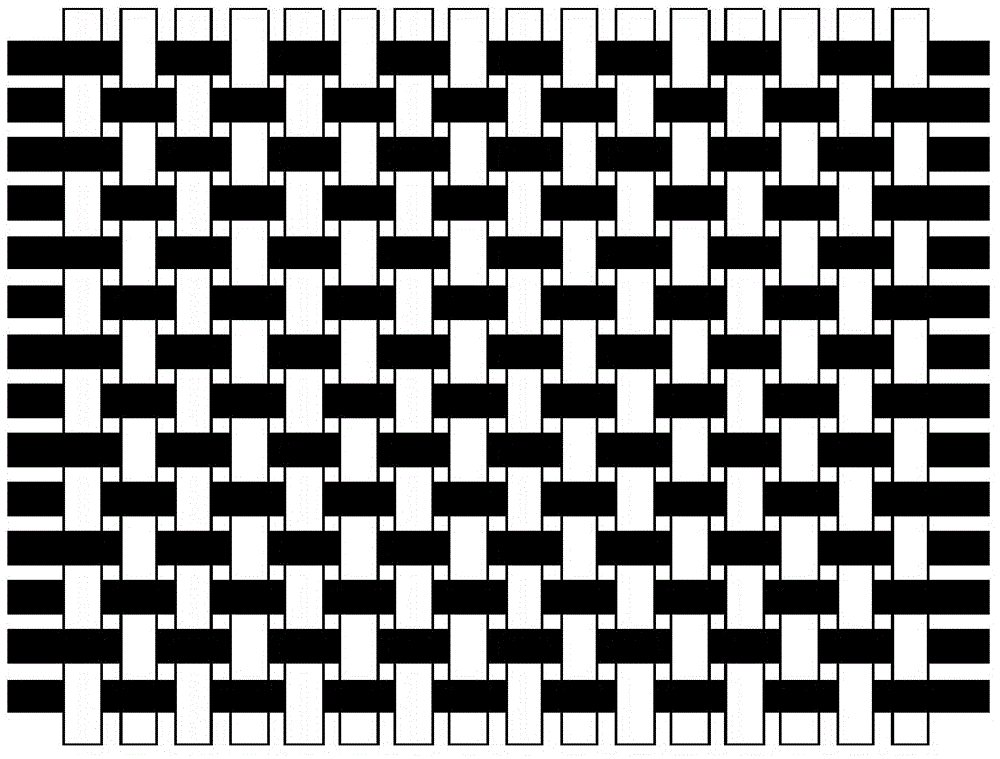

[0028]The warp yarn is 40D / 34F nylon yarn, and the weft yarn is composite yarn of modified high-shrinkage nylon and ordinary polyester. The mass ratio of nylon and polyester is 7:3, and the composite yarn is 50D / 24F. The weave is 3 / 1 twill weave on an air jet loom. The woven fabric blank adopts the following post-processing technology:

[0029] 1. Desizing: Put the aforementioned woven fabric blank into the dyeing vat for desizing treatment. The components of the desizing finishing solution are: 30% caustic soda 14.5g / L, degreasing agent 1.5g / L, chelating Dispersant 0.5g / L. The following desizing process is adopted: add water according to the bath ratio of 1:10, raise the temperature of the water to 40°C, add the desizing finishing solution, and circulate the water for 5 to 10 minutes, and raise the temperature to 1.5°C / min. 100°C and then keep warm for 85 minutes, then cool down to 65°C at a rate of 1.5°C / min, then overflow and cool down to 40°C, and drain the water out of ...

Embodiment 2

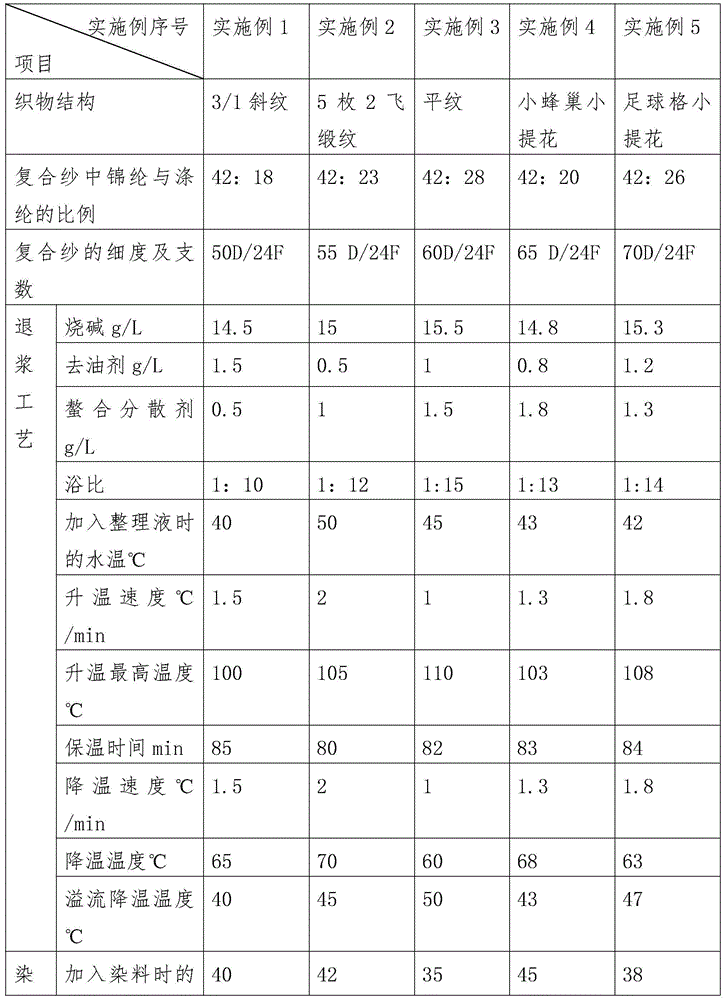

[0033] Each parameter is shown in Table 1, and all the other are with embodiment 1.

Embodiment 3-5

[0035] Each parameter is shown in Table 1, and all the other are with embodiment 1.

[0036] Table 1: Parameters and performance indicators of cashmere fabric examples

[0037]

[0038]

[0039] Table 2: The performance index table of the cashmere fabric prepared by conventional methods such as fiber opening, napping, napping, and cutting pile:

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com