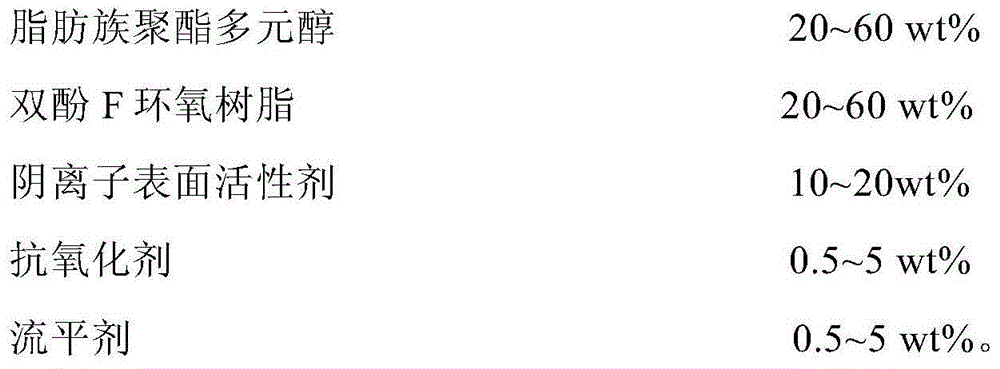

A carbon fiber composite emulsion sizing agent having low viscosity and a preparing method thereof

A composite emulsion and carbon fiber technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of unsuitable reinforced resin-based composite materials and low bonding strength, so as to improve sizing efficiency and uniformity, excellent performance, Reduces the effect of sizing differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

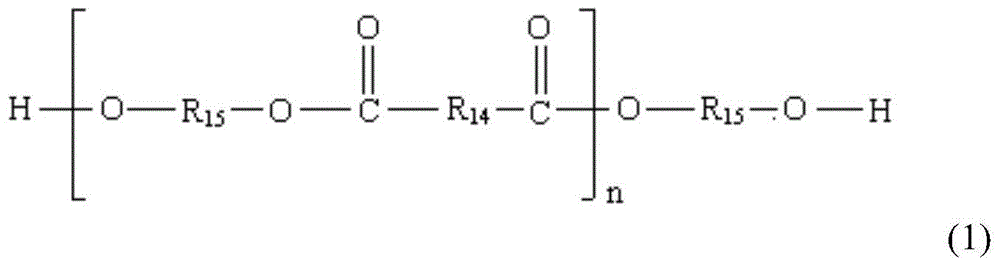

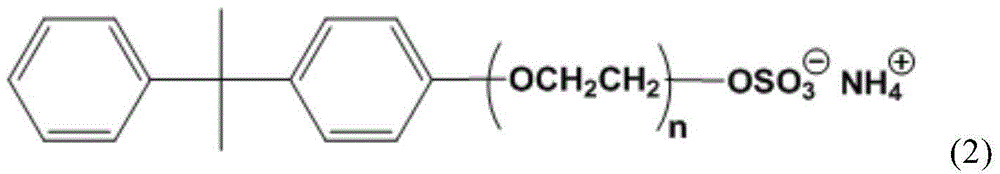

Method used

Image

Examples

Embodiment

[0049] Take quantitative polyester polyol components (synthesized by Shanghai Institute of Organic Chemistry), epoxy resin components (produced by Shell Corporation of the United States), and 2,6-di-tert-butyl-p-cresol (produced by Sinopharm Group) and add them to 500ml In a four-neck flask, stir slowly at 90°C for 20 minutes until the mixture is uniform, and then stir at high speed for 20 minutes. Then add a certain amount of anionic surfactant (synthesized by Shanghai Organic Institute) and polyether-modified polysiloxane BNK-LK380 (produced by BNK Company in the United States), stir at high speed for 20 minutes, and then gradually lower the temperature. When the temperature in the flask dropped to 75°C, deionized water was added dropwise to the flask and the stirring was continued at a high speed. When the total amount of dripping water reaches a certain quality, the reaction is stopped to obtain a carbon fiber composite sizing agent emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com