Fiber polymerized concrete external wall panel

A technology of fiber polymerization and concrete, which is applied in the field of building panels, can solve the problems of high water absorption, cracking of external wall panels, peeling off, etc., and achieve the effect of beautiful appearance, reducing building sinking, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

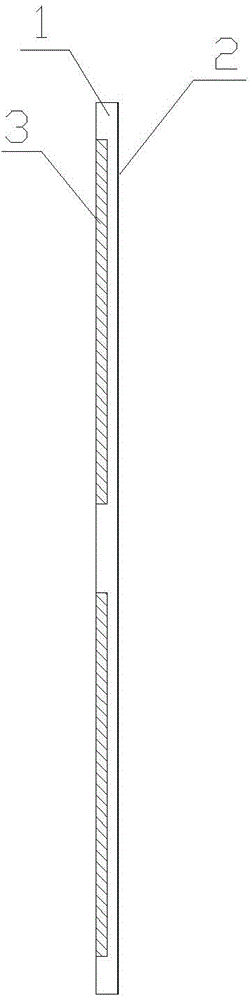

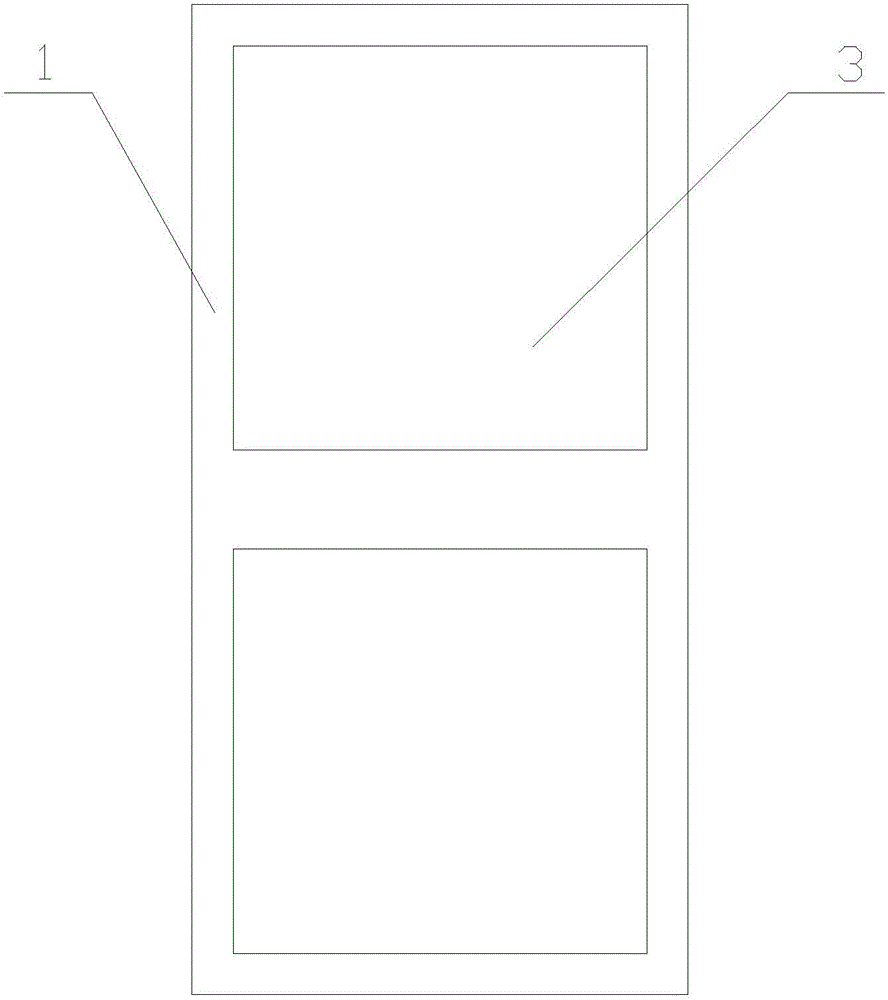

[0019] like Figure 1 to Figure 4 As shown, the fiber-polymerized concrete exterior wall panel includes a surface concrete layer 1 and a bottom insulation material layer 3, and a fiber material layer is also arranged in the concrete layer 1, and the fiber material layer is bonded and solidified with the concrete through an adhesive, and the concrete layer 1 The upper surface of the surface concrete layer 1 is also provided with a colored layer 2 through bonding and curing of the adhesive with the thermal insulation material layer 3 .

[0020] In this embodiment, the binder is resin glue, and the concrete layer 1 includes sandstone, corundum powder or perlite, and also includes fillers. The fillers can be selected from expansive soil or pottery clay, and the fiber material can be glass fiber, carbon fiber or woven cloth. Materials include perlite, PU wool, asbestos or glass fiber wool, resin glue mixed with sand, expansive soil, etc., bonded with glass fiber and thermal insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com