Metal rubber bearing and sealing-based expandable liner hanger joint

A liner hanger, metal rubber technology, used in sealing/packaging, drill pipe, casing, etc., can solve the problems of rubber not resistant to high temperature, insufficient bearing capacity, easy to age, etc., to increase friction and bearing capacity The effect of improving and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

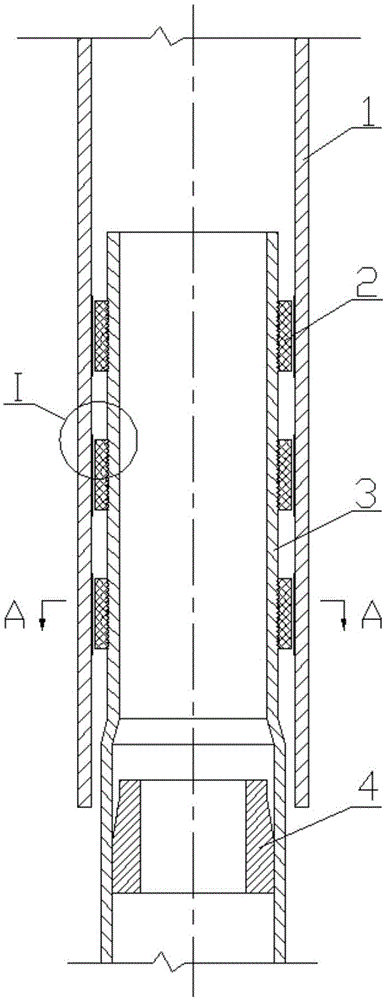

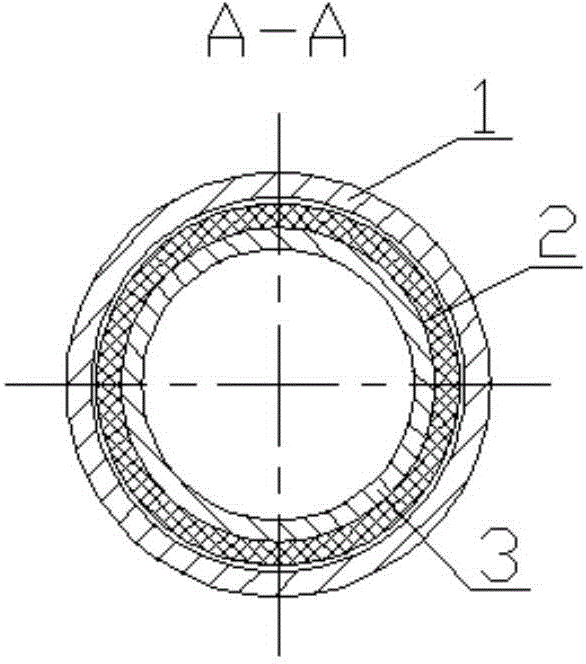

[0025] In conjunction with the accompanying drawings, further describe the specific implementation process of the present invention, as figure 1 , image 3 , Figure 4 , Image 6 shown.

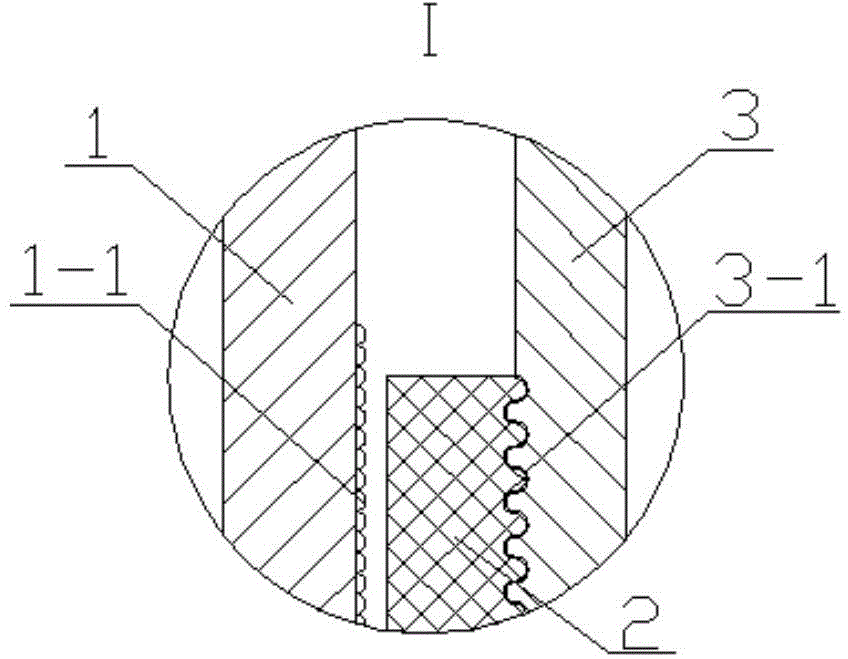

[0026] The present invention includes casing 1, variable diameter tail pipe 3, expansion cone 4, and metal rubber cylinder 2. The outer wall of the upper section of variable diameter tail pipe 3 is equipped with metal rubber cylinder 2 equidistantly. Outside the tail pipe 3, the expansion cone 4 is installed at the lower end of the tail pipe 3; the rubber barrel 2 is made of metal rubber material, and the outer wall of the tail pipe 3 matched with the metal rubber barrel 2 has a rough surface structure with knurling treatment 3- 1; The inner wall of the mating part of the bushing 1 and the metal rubber cylinder 2 has a rough surface structure 1-1 after sandblasting.

[0027] Taking the 140*114 expansion hanger as an example, the specification of the main part of the variable diameter tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com