A supercritical carbon dioxide jet jet drilling device for hydrate production

A carbon dioxide and jet drilling technology, which is used in liquid/gas jet drilling, production of fluids, and earth-moving drilling, etc., can solve the problems of blocking the gas decomposition pathway, reducing the ultimate recovery factor, and reducing the production of hydrate reservoirs. Reduce the potential risk of formation instability and blowout accidents, maintain integrity and geomechanical stability, and prevent blowout accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

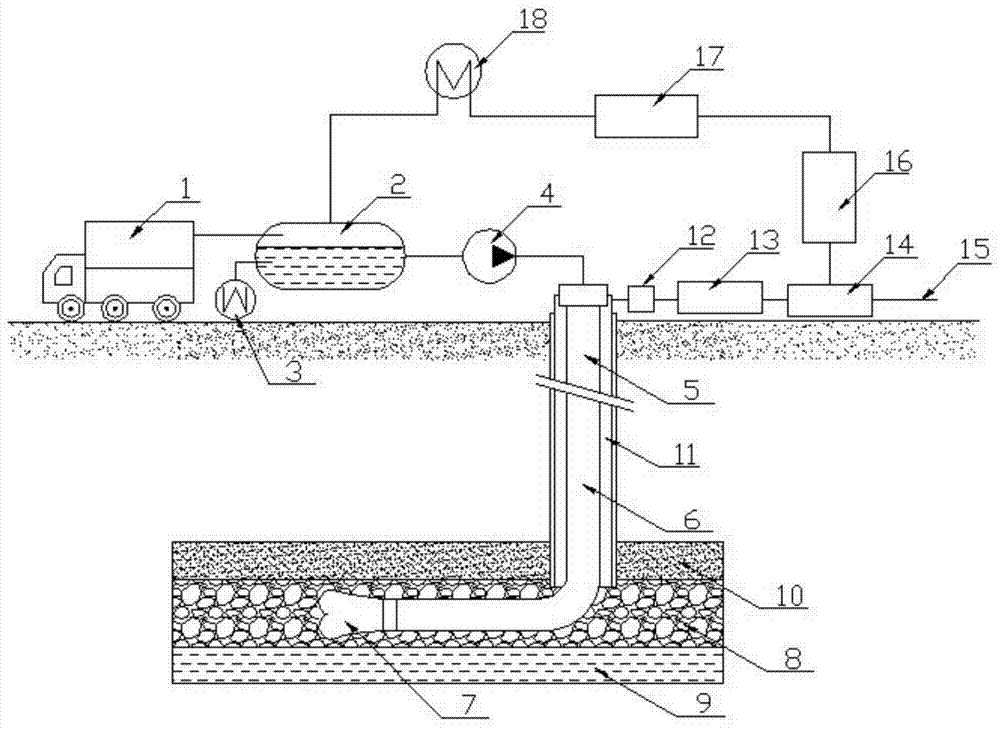

[0015] The main structure of the supercritical carbon dioxide jet jet drilling and mining hydrate device described in this embodiment includes a carbon dioxide tank car 1, a liquid carbon dioxide storage device 2, a storage tank refrigeration device 3, a high-pressure plunger pump 4, an upper drill pipe 5, and a lower drill pipe 6 , drill bit 7, hydrate reservoir 8, underlying formation 9, overlying rock formation 10, wellbore annulus 11, wellhead throttling device 12, three-phase separator 13, gas separator 14, natural gas production pipeline 15, carbon dioxide collection Device 16, gas compressor 17 and refrigeration pipeline 18; the tail of the carbon dioxide tank truck 1 is connected to the liquid carbon dioxide storage device 2, the lower side of the liquid carbon dioxide storage device 2 is connected to the storage tank refrigeration device 3, and the top of the liquid carbon dioxide storage device 2 is connected to the return drilling The liquid refrigeration pipeline 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com