Gas replacement method and device used for rigid container and based on quantitative gas extracting-inflating technology

A rigid container, gas replacement technology, applied in container filling method, container discharge method, fixed capacity gas storage tank, etc., can solve the problem of low pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

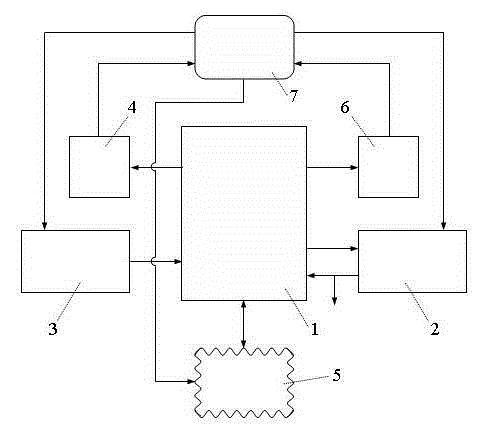

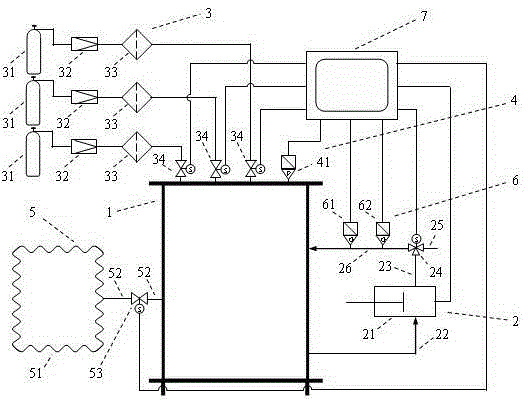

[0134] figure 2 Shows the gas replacement device of Example 1 of the present invention, the gas replacement device includes a rigid container 1, air extraction and gas mixing assembly 2, raw material gas filling assembly 3, pressure sensing assembly 4, pressure balance assembly 5, gas Concentration sensing component 6 and programmable logic controller 7.

[0135] The rigid container 1 is made of hard materials such as metal, plastic or glass. The thickness of the container wall is generally 1mm-3mm, and the volume of the gas phase space in the container is generally 10-1000L.

[0136] The air extraction and gas mixing assembly 2 includes an air pump 21 , an air extraction pipe 22 , an air delivery pipe 23 , a three-way electromagnetic valve 24 , an exhaust pipe 25 and a gas return pipe 26 . One end of the suction pipe 22 communicates with the rigid container 1 , and the other end communicates with the input end of the air pump 21 . The output end of the air pump 21 is conne...

Embodiment 2

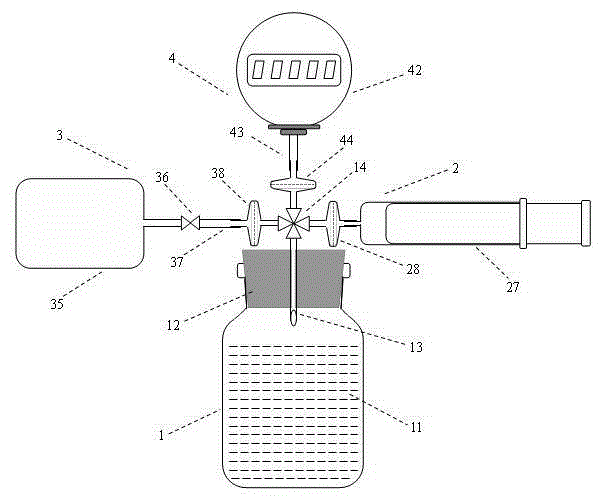

[0184] image 3 Shown is the gas replacement device of Example 2 of the present invention, which includes a rigid container 1 , an air extraction and gas mixing component 2 , a raw material gas filling component 3 , and a pressure detection component 4 .

[0185]The rigid container 1 is a glass bottle or a hard plastic bottle, the thickness of the container wall is generally 2-3mm, and the volume of the gas phase space in the container is generally 1mL-100mL. There is a circular opening on the rigid container 1, and the silicone sealing plug 12 is tightly plugged in the circular opening. The injection needle 13 penetrates the silicone sealing plug 12 and is inserted into the gas phase space of the container. The outer end of the injection needle 13 is connected to one of the four-way valves 14. port.

[0186] The gas extraction and gas mixing assembly 2 includes a gas injector 27 and a gas filter 28 . The gas injector 27 is connected to a gas filter 28 which is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com