Method for measuring bleeding property of cement paste employing hydrogen proton low-field nuclear magnetic resonance technique

A low-field nuclear magnetic resonance and cement slurry technology, applied in the field of building materials, can solve the problems of impermeability, frost resistance and corrosion resistance, the actual water-cement ratio of fresh concrete, the actual volume and the adverse effects of volume stability, weak layer The problem of uneven quality, to achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

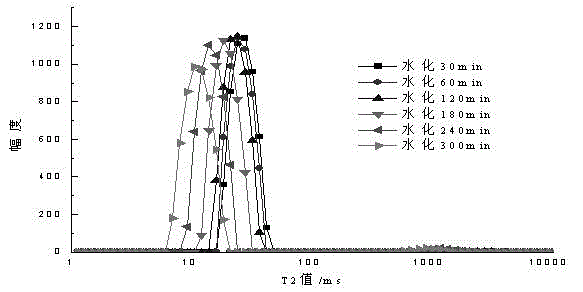

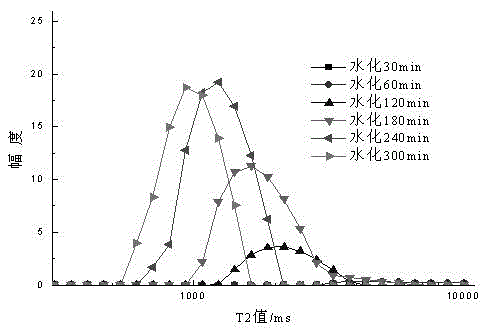

[0040] Test material: cement is P.O 52.5 grade, specific surface area is 396.5 kg / m 3 , the water consumption for the standard consistency is 141g, the initial setting is 1h20min, the final setting is 3h42min, the water-cement ratio used for the example test is 0.5, the expansion loss is 32% in 120min, and 67% in 300min. The test equipment and parameters are: MICRO-MR20 nuclear magnetic resonance analyzer is used for the test, CPMG pulse sequence is used, the number of echoes is n=18000, the echo time is 2τ=100μs, each CPMG signal scans m=8 times on average, and Repeat decay. The resampling waiting time TW is 18000ms. According to the calculation method mentioned above, the bleeding coefficient can be obtained.

[0041] figure 1 and figure 2 T is the cement paste with different hydration time 2 distribution and T representing the bleeding peak 2 curve.

[0042] Substitute the data in the figure into the calculation formula (2) to obtain the bleeding coefficient of the ...

Embodiment 2

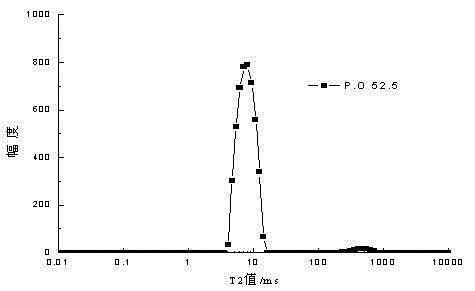

[0046] Test material: cement is P.O 52.5 grade, specific surface area is 396 m 3 / kg, the water consumption of the standard consistency is 141g, the experiment controls the fluidity (200mm±5mm), adjusts the water-cement ratio of the slurry for the bleeding test, and the water-cement ratio of the slurry for the bleeding test is 0.44. The nuclear magnetic resonance test equipment and parameters are: MICRO-MR20 nuclear magnetic resonance analyzer is used for the test, CPMG pulse sequence is used, the number of echoes is n=18000, the echo time is 2τ=100μs, and each CPMG signal scans m=8 times on average , and repeated decay. The resampling waiting time TW is 18000ms. Will image 3 The data in is calculated by formula (2) to get the bleeding coefficient K was 1.65%. Test the bleeding rate according to JC / T 2153-2012 "Test Method for Bleeding of Cement" to get the bleeding rate B w was 1.61%.

Embodiment 3

[0048] Test material: cement is P.O 32.5 grade, specific surface area is 384 m 3 / kg, the water consumption of the standard consistency is 113g, the experiment controls the fluidity (200mm±5mm), adjusts the water-cement ratio of the slurry for the bleeding test, and the water-cement ratio of the slurry for the bleeding test is 0.41. The nuclear magnetic resonance test equipment and parameters are: MICRO-MR20 nuclear magnetic resonance analyzer is used for the test, CPMG pulse sequence is used, the number of echoes is n=18000, the echo time is 2τ=100μs, and each CPMG signal scans m=8 times on average , and repeated decay. The resampling waiting time TW is 18000ms. Will Figure 4 The data in is calculated by formula (2) to get the bleeding coefficient K 2.25%. Test the bleeding rate according to JC / T 2153-2012 "Test Method for Bleeding of Cement" to get the bleeding rate B w was 2.18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bleeding rate | aaaaa | aaaaa |

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com