Precise positioning table capable of switching stations

A positioning table and station technology, which is applied in the direction of photolithography exposure equipment, microlithography exposure equipment, etc., can solve the problems of large vertical space, complex structure, and multiple vertical layers of mask tables, and achieve vertical layers Less, simple structure, saving vertical space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

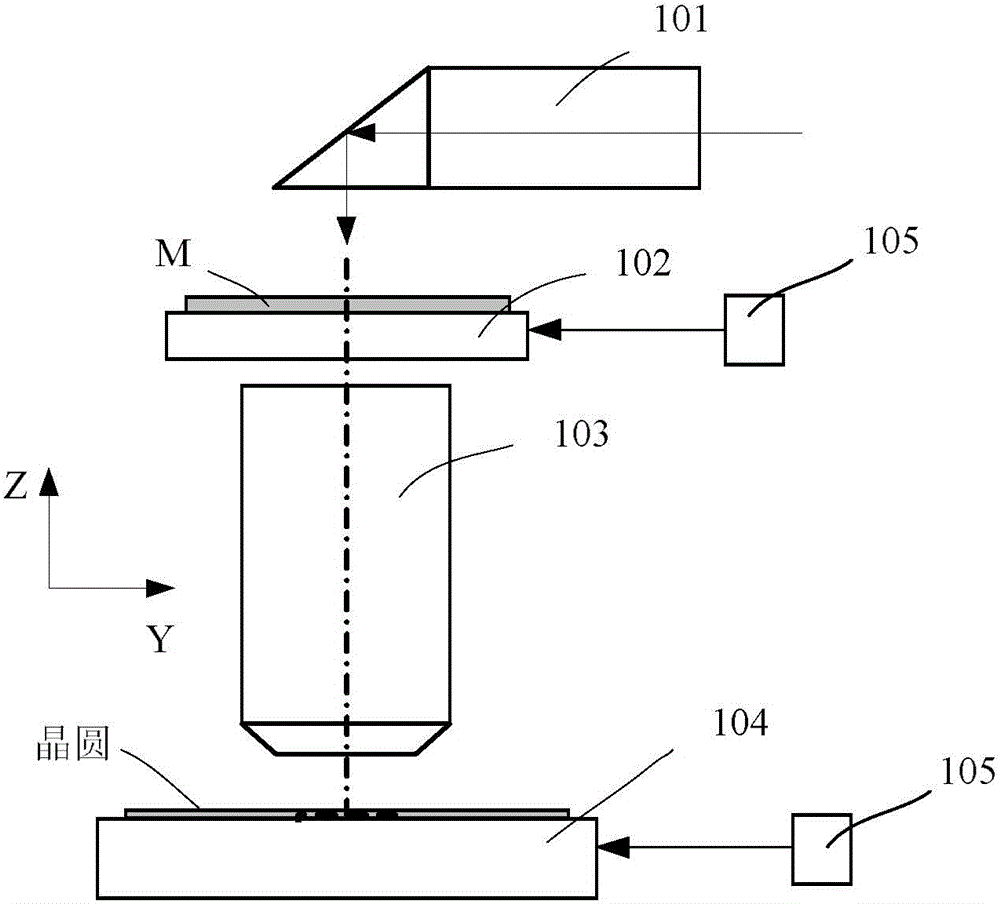

[0039] Please refer to figure 2, the lithography machine mainly includes an illumination system 101 , a mask table 102 , a projection objective lens 103 , a workpiece table 104 , and a laser interferometer 105 . The illumination system 101 provides the exposure light source for the exposure device, the mask table 102 supports and positions the carrying object (M), and the projection objective lens provides the exposure field of view to expose the pattern on the carrying object (M) on the silicon wafer. The workpiece table 104 carries silicon wafers and provides support and positioning functions for silicon wafers / glass substrates. Laser interferometer 105 provides position signals for precise motion control of workpiece stage 104 and mask stage 102 . The carrying object 205 may be a reticle, a silicon wafer or a wafer substrate.

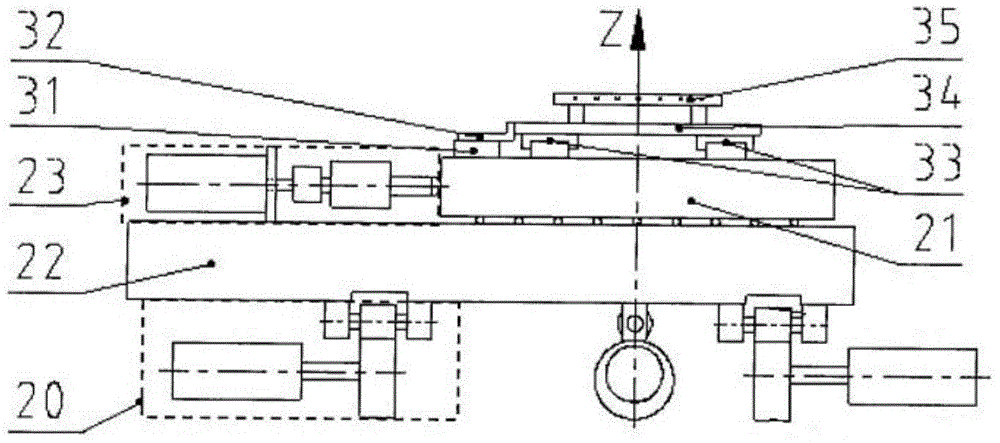

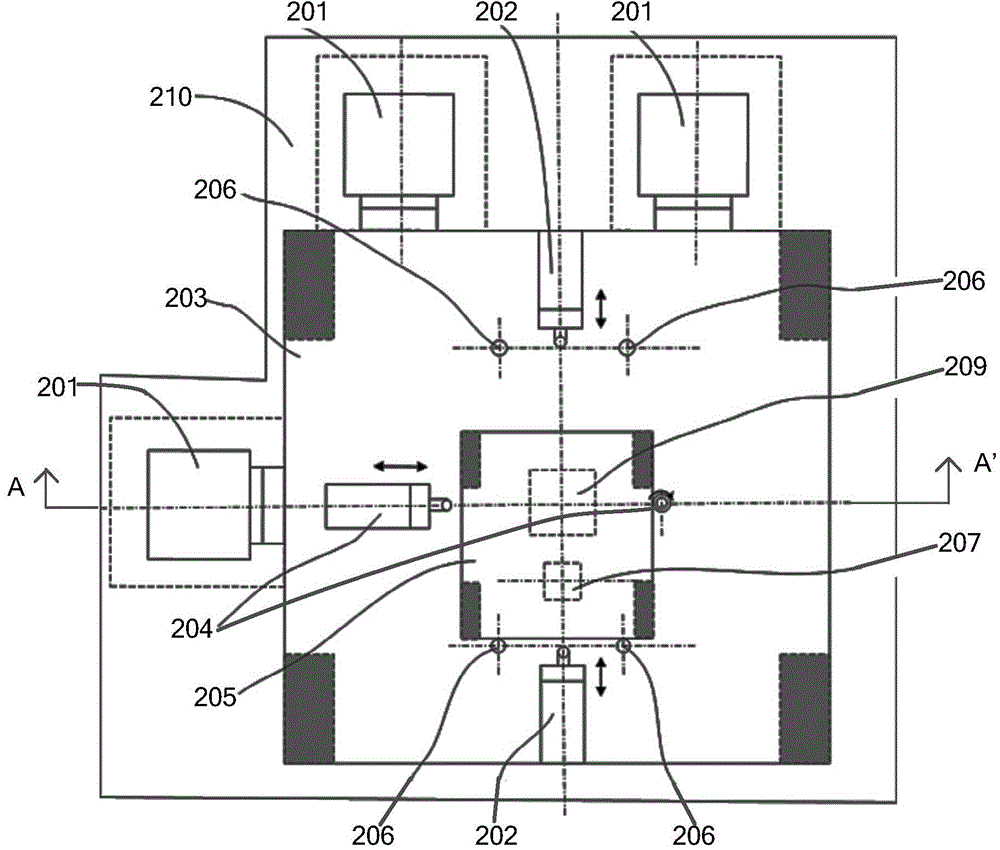

[0040] Please refer to image 3 , and combined with Figure 4 and Figure 5 , this embodiment provides a precision positioning mask table capa...

Embodiment 2

[0054] Please refer to Figure 7 , the difference between this embodiment and Embodiment 1 is that the air bearing 302 includes several air bearing areas, and each of the air bearing areas includes a positive pressure area ring 701 and a vacuum area ring 702, each of the The positive pressure zone ring 701 in the air flotation zone is set outside the vacuum zone ring 702 .

[0055] To sum up, the present invention directly utilizes two clamping mechanisms 202 to push the carrying object, and then realizes the movement of the carrying object. Compared with the movement of the carrying object driven by the movement of the carrying platform in the prior art, the structure is simpler. The vertical space is saved, and at the same time, the present invention realizes the functions of positioning and guiding by using several limit pins and switching guide devices, and can ensure that the movement of the loaded object is carried out between required stations. A mask table with less v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com