Anti-nuclear radiation composite flexible material and preparing method thereof

A technology of anti-nuclear radiation and flexible materials, applied in the field of anti-nuclear radiation, can solve the problems of difficult construction and heavy weight, and achieve the effects of good shielding and radiation effects, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention also provides a preparation method of a nuclear radiation-proof composite flexible material, comprising:

[0062] The non-woven fabric is subjected to thermal cross-linking treatment after being immersed in an emulsion including acrylic resin, PE resin, cross-linking agent and water; the non-woven fabric is made of polymer fibers and stainless steel fibers;

[0063] Drying and cold-rolling the non-woven fabric obtained by thermal cross-linking treatment to obtain a nuclear radiation-proof composite flexible material.

[0064] The present invention uses non-woven fabric as the main body material of anti-nuclear radiation composite flexible material, and described non-woven fabric is preferably prepared according to the following method:

[0065] After mixing stainless steel fibers and polymer fibers, they are opened and carded to obtain nascent fiber webs;

[0066] The nascent fiber web is tiled by a cross-lapper to obtain a fluffy fiber web;

[0...

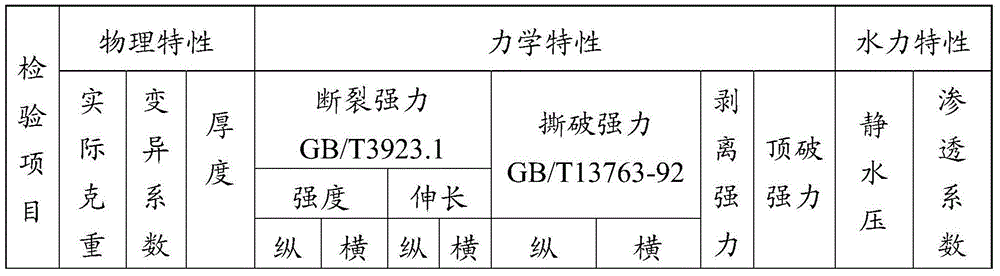

Embodiment 1

[0101] Mix stainless steel fibers with a fineness of 3.0-6.0dtex and a length of 56-65mm and polypropylene fibers with a fineness of 3.0-6.0dtex, a length of 56-65mm and a strength of 70CN / dtex at a ratio of 0.1:1. The fiber after mixing forms nascent fiber web after opening and carding; Said nascent fiber web is flat-laid into 200g / m through poor web-laying machine 2 The fluffy fiber web; the fluffy fiber web is consolidated and compounded by needle punching up and down, and the needle punching density is 300 punches / cm 2 , to obtain a nonwoven fabric with a thickness of 2mm;

[0102] The non-woven fabric is immersed in the emulsion comprising 5.0wt% acrylic resin, 5.0wt% PE resin, 1.0wt% SAden163 crosslinking agent and 89wt% water, so that the amount of sizing is 5.0wt%; The non-woven fabric impregnated with the emulsion is cross-linked and compounded at a temperature of 110±2°C, then dried at a temperature of 130±2°C, and then entered into a cold rolling mill at a temperat...

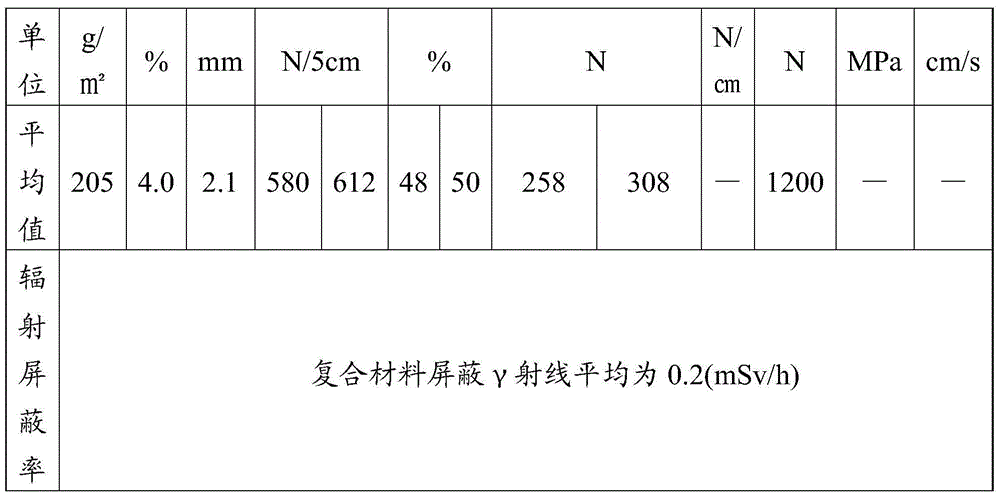

Embodiment 2

[0108] Mix stainless steel fibers with a fineness of 3.0-6.0dtex and a length of 56-65mm and polypropylene fibers with a fineness of 3.0-6.0dtex, a length of 56-65mm and a strength of 70CN / dtex at a ratio of 0.1:1. The fiber after mixing forms nascent fiber web after opening and carding; Said nascent fiber web is flattened into 500g / m 2 The fluffy fiber web; the fluffy fiber web is consolidated and compounded by needle punching up and down, and the needle punching density is 300 punches / cm 2 , to obtain a nonwoven fabric with a thickness of 4mm;

[0109] The non-woven fabric is immersed in the emulsion comprising 5.0wt% acrylic resin, 5.0wt% PE resin, 1.0wt% SAden163 crosslinking agent and 89wt% water, so that the amount of sizing is 5.0wt%; The non-woven fabric impregnated with the emulsion is cross-linked and compounded at a temperature of 110±2°C, then dried at a temperature of 130±2°C, and then entered into a cold rolling mill at a temperature of 10±0.5°C to be rapidly co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com