Equipment for performing surface treatment on graphene workpieces as well as treatment method of equipment

A surface treatment and graphene technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of large environmental pollution, high production costs, and great harm to human body, and achieve simple equipment operation, improved production efficiency, The effect of short cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

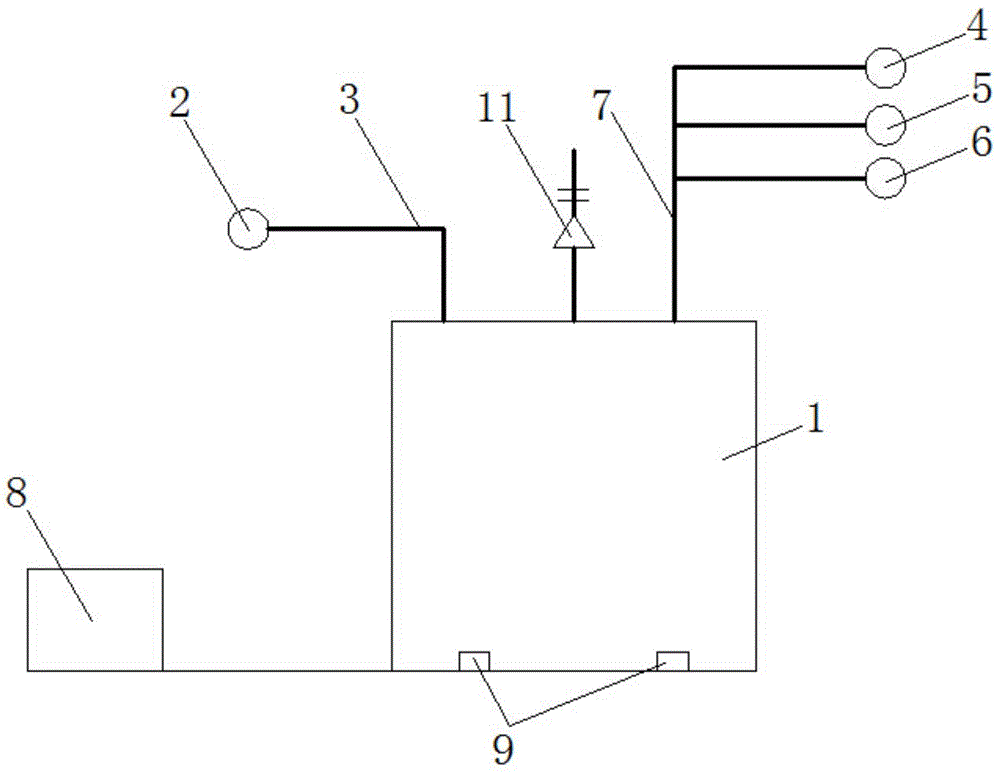

[0031] See figure 1 , the present embodiment carries out the equipment of surface treatment to graphene parts, comprises vacuum chamber 1, vacuum pump 2, pumping pipeline 3, fills N 2 Device 4, charging Ar device 5, charging O 2 A device 6, an inflation pipe 7, an electric control device 8 and at least one pair of electrodes 9.

[0032] A balance valve 11 is provided on the vacuum chamber 1 . The vacuum pump 2 communicates with the vacuum chamber 1 through an exhaust pipe 3 . Charge N 2 Device 4, Ar charging device 5 and O charging 2 The device 6 communicates with the vacuum chamber 1 through the gas-filled pipeline 4 . The electrode 6 is arranged in the vacuum chamber 1 and connected with the electric control device 8 .

[0033] The processing method of the equipment of carrying out surface treatment to graphene parts of the present embodiment, comprises the following steps:

[0034] ①. Put in the graphene parts, close the vacuum chamber 1, then turn on the vacuum pump...

Embodiment 2

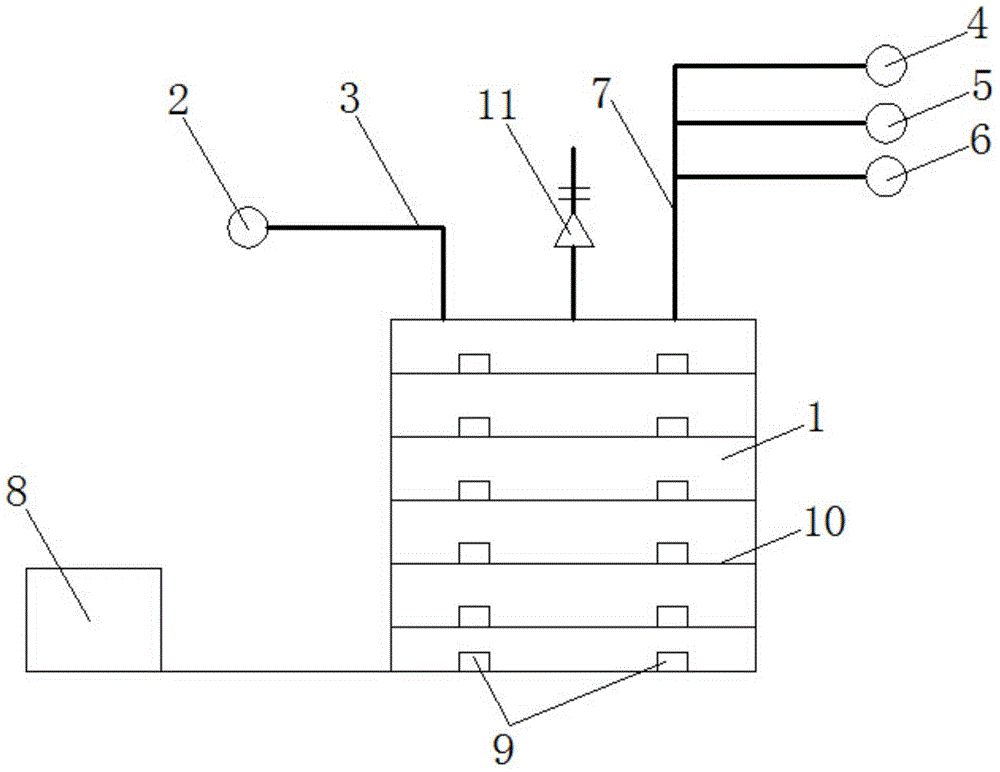

[0047] See figure 2 , This embodiment is basically the same as Embodiment 1, except that it also includes a plurality of partitions 10 arranged in the vacuum chamber 1 , and each partition 10 is provided with a pair of electrodes 6 .

[0048] The equipment for surface treatment of graphene parts in this embodiment has higher production efficiency and is more suitable for large-scale and batch production requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com