Carbon nanotube thin-film transistor, AMOLED (active matrix organic light emitting diode) pixel flexible driving circuit and manufacturing method thereof

A carbon nanotube thin film and carbon nanotube technology are applied in AMOLED pixel flexible driving circuit and its production, carbon nanotube thin film transistor and its production field, which can solve the problem that the OLED light-emitting requirements cannot be met, and the transistor mobility is low and cannot be guaranteed. Flexibility and other issues, to avoid layer jump connections, low operating voltage, and low hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

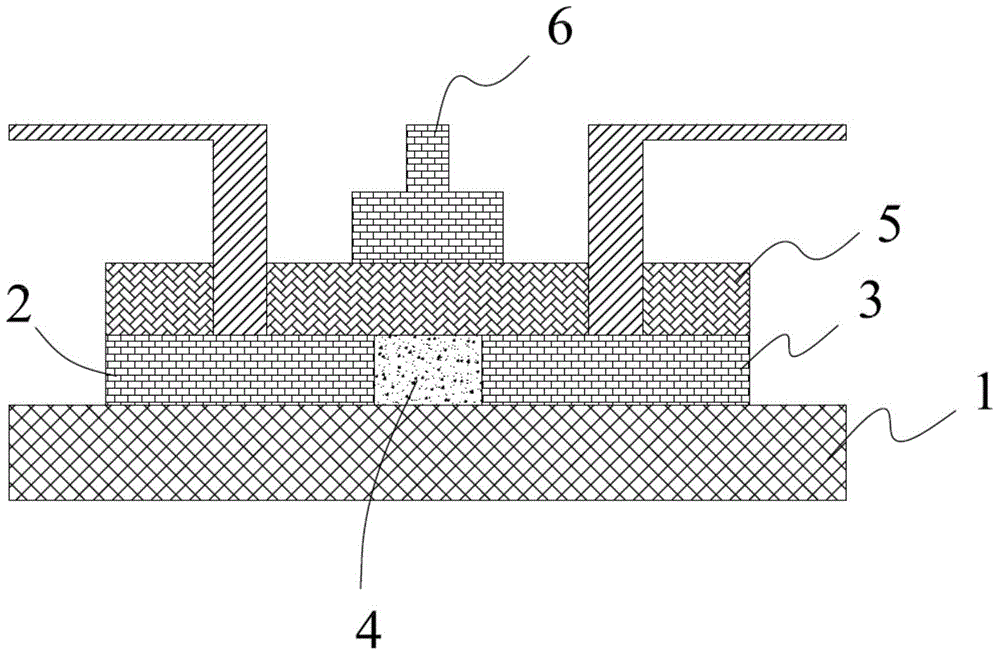

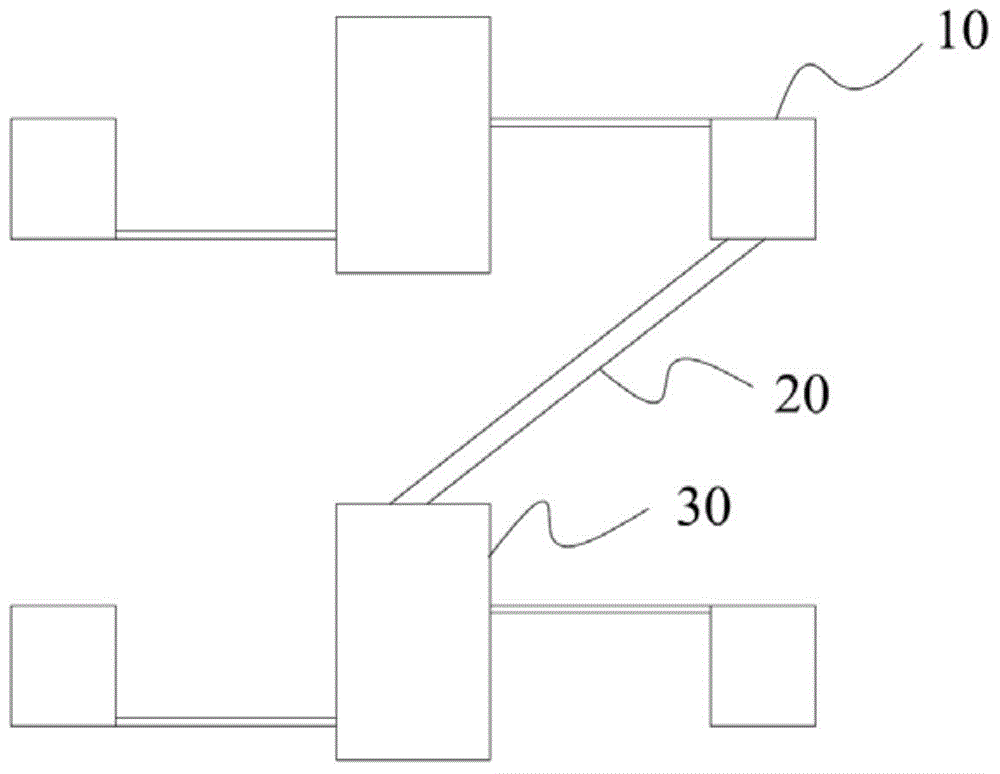

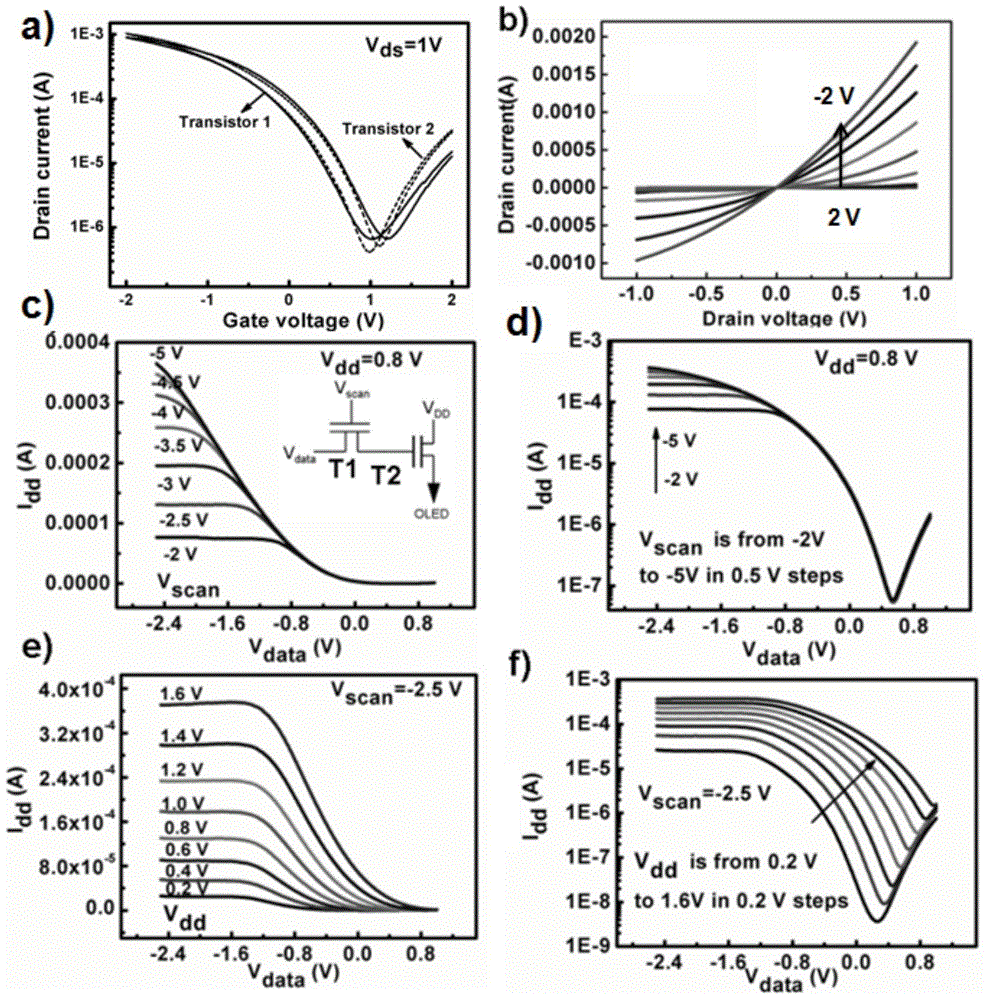

[0032] The inventors have confirmed through a large number of test results that the performance of the inorganic thin film transistor device with carbon nanotubes as the active layer is well beyond the basic requirements of OLED light emission. And the performance of the polymer-separated semiconductor large-diameter carbon nanotubes used in the present invention has been greatly improved, which is no worse than that of silicon-based semiconductor transistors. Carbon nanotube conductive materials can be solubilized, and flexible drive circuits can be prepared by printing, so the solubilized carbon nanotubes can be deposited on flexible substrate materials by inkjet printing, screen printing or roller printing, avoiding the traditional patterning processing method. The OLED luminescent material itself can also be made into a solution, and a flexible display device can be prepared by printing. Therefore, the present invention can promote the integration of the flexible driving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com