White-light OLED (organic light emission diode) device and preparation method thereof

An electroluminescent device and a technology of a blue light-emitting layer, which are applied in circuits, electrical components, and electric solid-state devices, can solve problems such as difficult white light emission, and achieve the effects of increasing brightness, enhancing yellow light emission, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

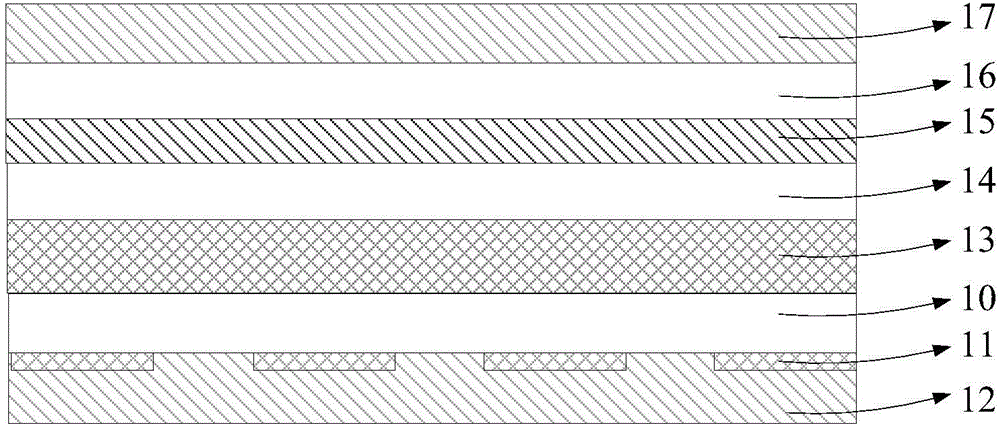

[0045] A method for preparing a white light organic electroluminescence device, comprising the following steps:

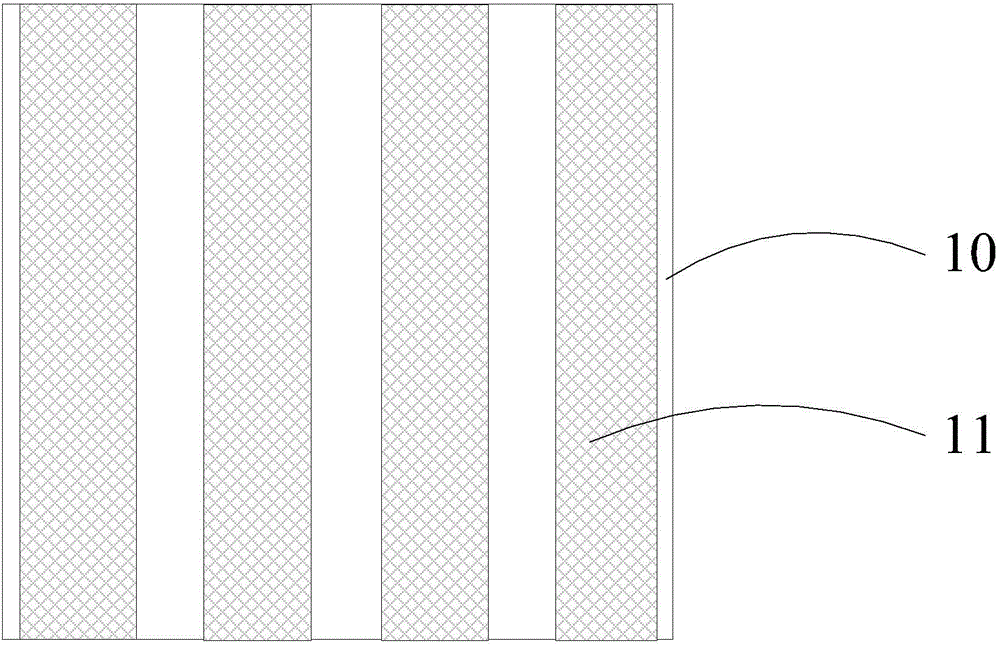

[0046] (1) Provide an ITO conductive glass with a sheet resistance of 5Ω / □ and clean it; prepare a color conversion layer on the side of the ITO conductive glass that is not covered with the ITO film (that is, the side of the glass substrate facing the air). Specifically, use a pre-established The mask plate is covered on the side of the conductive substrate that is not covered with ITO, forming blank areas arranged at intervals in strips, and the vacuum degree is 1×10 -5 In Pa's vacuum coating system, the red light color conversion layer is prepared in the blank area by thermal resistance evaporation technology, and the coverage area of the red light color conversion layer on the glass substrate is 60% of the total light emitting area of the glass substrate; the red light color conversion layer The materials include Alq3 and DCM doped in Alq3, wherein the mass...

Embodiment 2

[0056] A method for preparing a white light organic electroluminescence device, comprising the following steps:

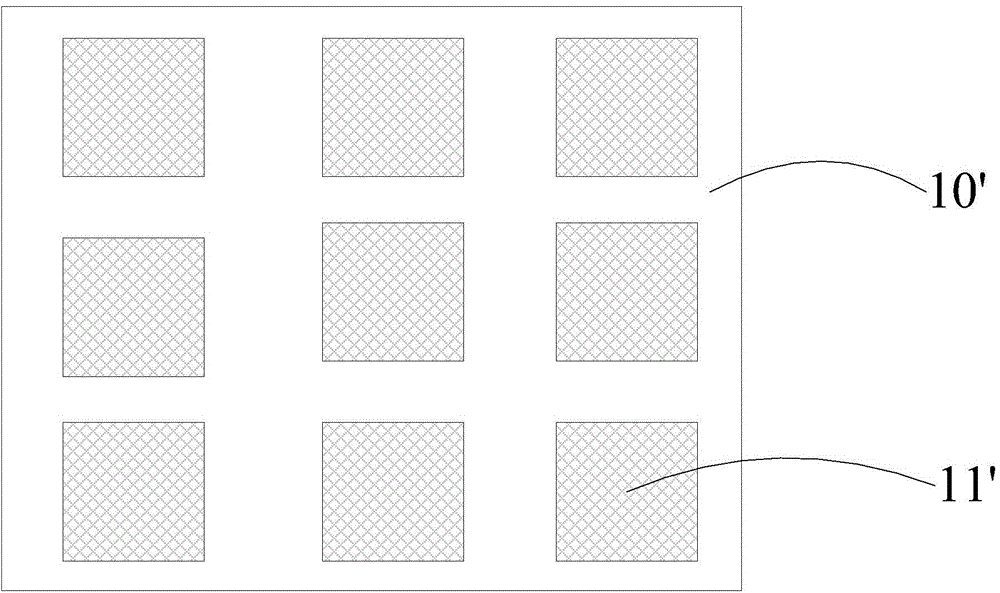

[0057] (1) Provide an ITO conductive glass with a square resistance of 100Ω / □ and clean it; prepare a color conversion layer on the side of the ITO conductive glass that is not covered with the ITO film (that is, the side of the glass substrate facing the air). Specifically, use a pre-established The mask plate is covered on the side of the conductive substrate that is not covered with ITO to form blank areas arranged at intervals in blocks, and the vacuum degree is 1×10 -3 In the vacuum coating system of Pa, the red light color conversion layer is prepared in the blank area by thermal resistance evaporation technology, and the coverage area of the red light color conversion layer on the glass substrate is 80% of the total light emitting area of the glass substrate; the red light color conversion layer The materials include Alq3 and DCM doped in Alq3, wherein t...

Embodiment 3

[0066] A method for preparing a white light organic electroluminescence device, comprising the following steps:

[0067] (1) Provide an ITO conductive glass with a square resistance of 20Ω / □ and clean it; prepare a color conversion layer on the side of the ITO conductive glass that is not covered with the ITO film (that is, the side of the glass substrate facing the air). Specifically, use a pre-established The mask plate is covered on the side of the conductive substrate that is not covered with ITO to form blank areas arranged at intervals in blocks, and the vacuum degree is 1×10 -3 In the vacuum coating system of Pa, the red light color conversion layer is prepared in the blank area by thermal resistance evaporation technology, and the coverage area of the red light color conversion layer on the glass substrate is 70% of the total light emitting area of the glass substrate; the red light color conversion layer The materials include Alq3 and DCM doped in Alq3, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com