Stacked-array liquid refrigeration type high-power semiconductor laser

A semiconductor and laser technology, applied in the field of high-power semiconductor lasers, can solve the problems that restrict the power improvement and application fields of semiconductor lasers, affect the reliability of semiconductor lasers, and reduce the service life and reliability of devices, so as to reduce electrothermal migration, simple structure, The effect of low risk of being corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Describe the present invention in detail below in conjunction with accompanying drawing and specific implementation example:

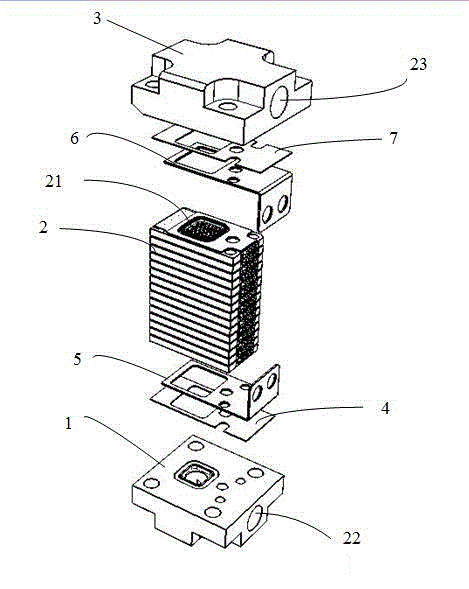

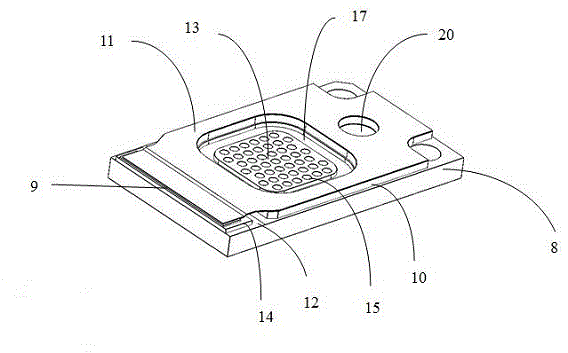

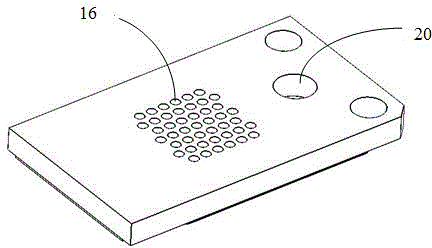

[0033] figure 1 It is a structural diagram of the stacked array liquid-cooled high-power semiconductor laser of the present invention, and the stacked array liquid-cooled high-power semiconductor laser includes a bottom water block 1, an insulating sheet a 4, and a positive electrode sheet 5 arranged sequentially from bottom to top , semiconductor laser module 2, negative electrode sheet 6, insulating sheet b 7 and upper water block 3. The semiconductor laser module 2 is formed by stacking a plurality of semiconductor laser units, which are connected in series, and a liquid cooling channel 21 is provided in the semiconductor laser module. figure 2It is a structural diagram of a semiconductor laser unit. The semiconductor laser unit includes a laser chip 9 , a liquid cooling sheet 8 , an insulating layer 10 and a negative electrode connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com