An automatic equalization control method without battery cell voltage sensor

A single voltage, automatic equalization technology, applied in charge equalization circuit, battery circuit device, arrangement of multiple synchronous batteries, etc., can solve the problems of long control cycle, reduced equalization efficiency, multi-resources, etc., to reduce energy waste , The effect of saving control time and reducing system volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

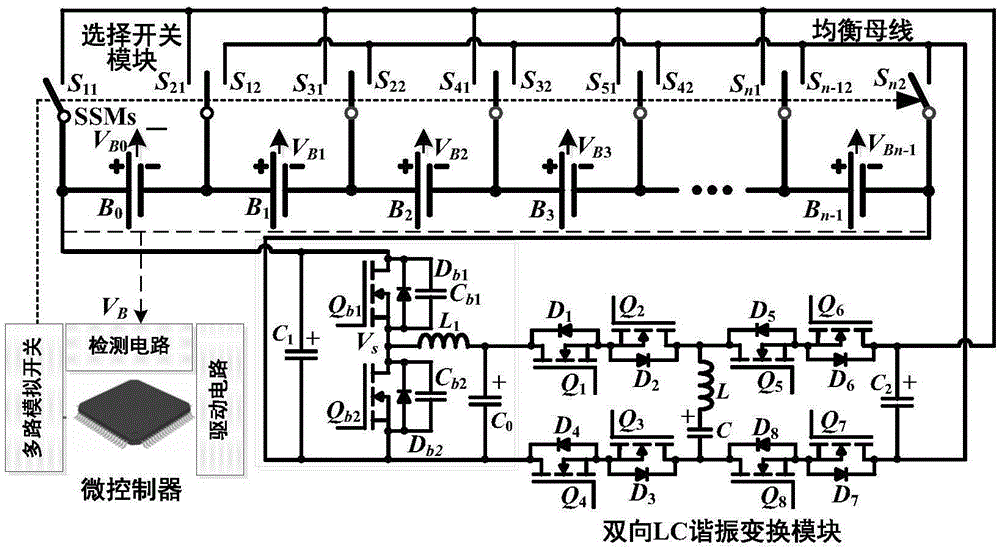

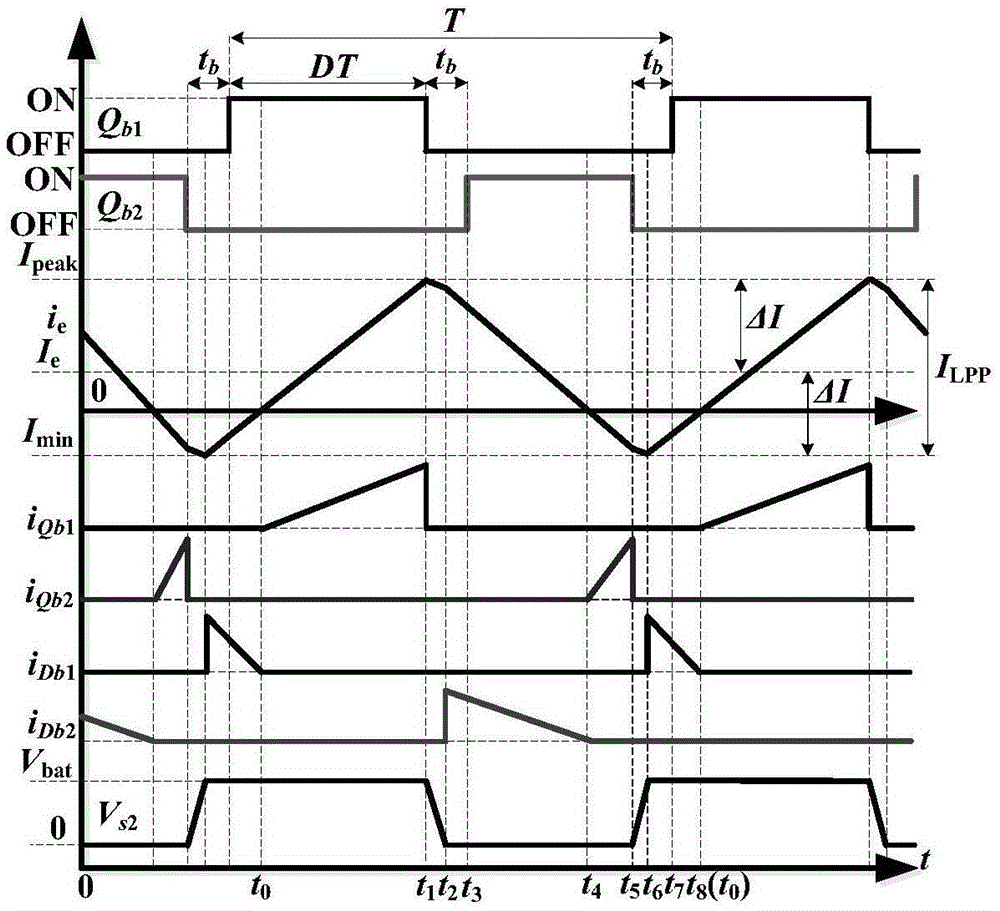

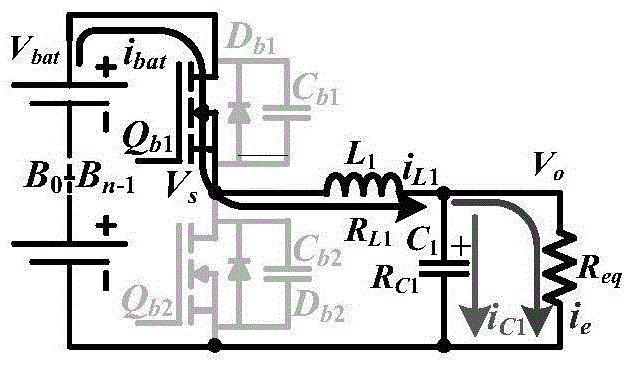

[0056] Such as figure 1 As shown, an equalization circuit based on Buck-Boost conversion and bidirectional LC resonant conversion, including microcontroller, balanced bus, Buck-Boost conversion circuit, bidirectional LC resonant conversion circuit, selection switch module, power battery pack and filter capacitor. The circuit realizes the soft switch equalization of battery pack to battery cell (Pack to Cell) or battery cell to battery pack (Cell to Pack) through Buck-Boost transformation and bidirectional LC resonance transformation. The working principle of this circuit is: the microcontroller obtains the average voltage of the cells according to the collected voltage of the battery pack, determines the balanced working mode by comparing the average voltage of the cells with the current balanced cell voltage, and controls the Buck-Boost conversion and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com