Method for preparing oil from whole grains of corns

A technology of corn kernels and corn oil, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of nutritional value discount, long process route, and loss of corn oil nutrients, so as to simplify the production process and reduce production costs , the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

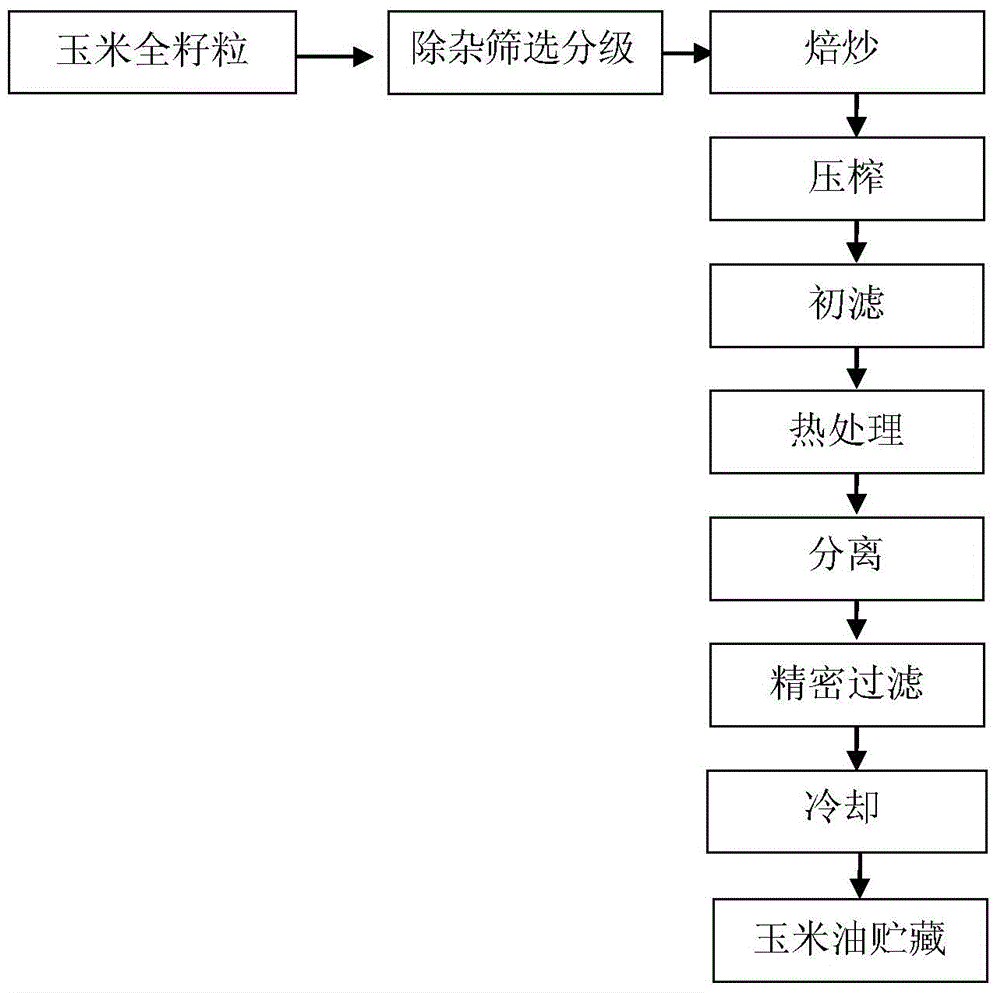

[0024] An example of the method for producing oil from corn whole grains of the present invention comprises the steps of:

[0025] Roast the screened plump corn kernels at 90°C for 1.4 hours, and the moisture content of the kernels is 7.2%; press the roasted corn kernels at a temperature of 90°C and a pressure of 45MPa; the squeezed oil juice Use a 150-mesh stainless steel screen to separate the oil residue, mix the separated residue and corn kernels at a ratio of 1:8 and press, heat the separated oil to 90°C at a stirring speed of 60r / min, and keep it warm for 0.5h; After layering, the oil is separated, and then fine-filtered with a 500-mesh filter cloth. The fine-filtered corn oil is cooled to room temperature, and stored away from light in a ventilated, dry, and hygienic environment. The main technical indicators of the corn oil obtained are as follows:

[0026] Color (Lovibond color cell 25.4mm): Y=30, R=4.9; acid value (KOH, mg / g): 2.5; peroxide value (mg / kg): 5.0; solve...

Embodiment 2

[0028] Another example of the method for producing oil from corn whole grains of the present invention comprises the following steps:

[0029] Roast the screened plump corn kernels at 100°C for 1.2 hours, and the moisture content of the kernels is 7.0%; press the roasted corn kernels at a pressing temperature of 100°C and a pressure of 40MPa; the squeezed oil juice Use a 160-mesh stainless steel screen to separate the oil residue, mix the separated residue and corn kernels at a ratio of 1:7 and then press, heat the separated oil to 100°C at a stirring speed of 60r / min, and keep it warm for 0.5h; After layering, the oil is separated, and then fine-filtered with a 500-mesh filter cloth. The fine-filtered corn oil is cooled to room temperature, and stored away from light in a ventilated, dry, and hygienic environment. The main technical indicators of the corn oil obtained are as follows:

[0030] Color (Lovibond color cell 25.4mm): Y=30, R=5.0; acid value (KOH, mg / g): 2.7; perox...

Embodiment 3

[0032] Another example of the method for producing oil from corn whole grains of the present invention comprises the following steps:

[0033] The screened plump corn kernels were roasted at 110°C for 1.1h, and the moisture content of the kernels was 6.6%; the roasted corn kernels were squeezed at a pressing temperature of 110°C and a pressure of 45MPa; the squeezed oil juice Use a 180-mesh stainless steel screen to separate the oil residue, mix the separated residue and corn kernels at a ratio of 1:9 and press, heat the separated oil to 110°C at a stirring speed of 50r / min, and keep it warm for 0.5h; After layering, the oil is separated, and then fine-filtered with a 450-mesh filter cloth. The fine-filtered corn oil is cooled to room temperature, and stored away from light in a ventilated, dry, and hygienic environment. The main technical indicators of the corn oil obtained are as follows:

[0034] Color (Lovibond color cell 25.4mm): Y=30, R=5.0; acid value (KOH, mg / g): 2.7;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com