Composite membrane containing sulfonic acid functionalized hollow nano hydrogel as well as preparation and application thereof

A sulfonic acid functionalized, hollow nanotechnology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of improved permeability, improved separation selectivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

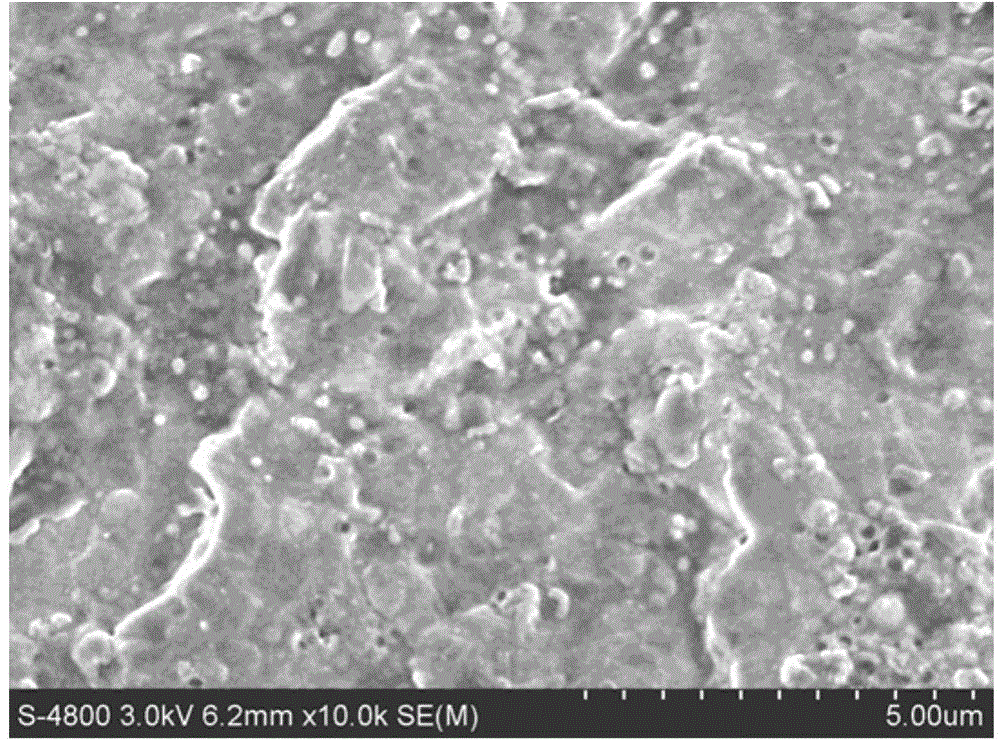

[0024] Example 1: Preparation of a composite membrane containing sulfonic acid functionalized hollow nano hydrogel.

[0025] The composite membrane has a thickness of 80 μm and is composed of 12.5 g of polyoxyethylene-polycaprolactam block copolymer with a mass fraction of 4% and 0.05 g of functionalized hollow nano-hydrogel, wherein the polyoxyethylene segment accounts for the block The mass fraction of the copolymer is 60%, the polycaprolactam segment accounts for 40% of the mass fraction of the block copolymer, and the functional group selected for the functionalized hollow nano hydrogel is a sulfonate group. The preparation steps are as follows:

[0026] Step 1, preparation of sulfonic acid functionalized hollow nano hydrogel:

[0027] Step 1-1. Add 240mL of absolute ethanol, 30mL of distilled water, and 6mL of ammonia water into a container. After stirring with a magnet for half an hour at room temperature, add an alcohol solution of tetraethoxysilane (18mL of tetraethoxy...

Embodiment 2

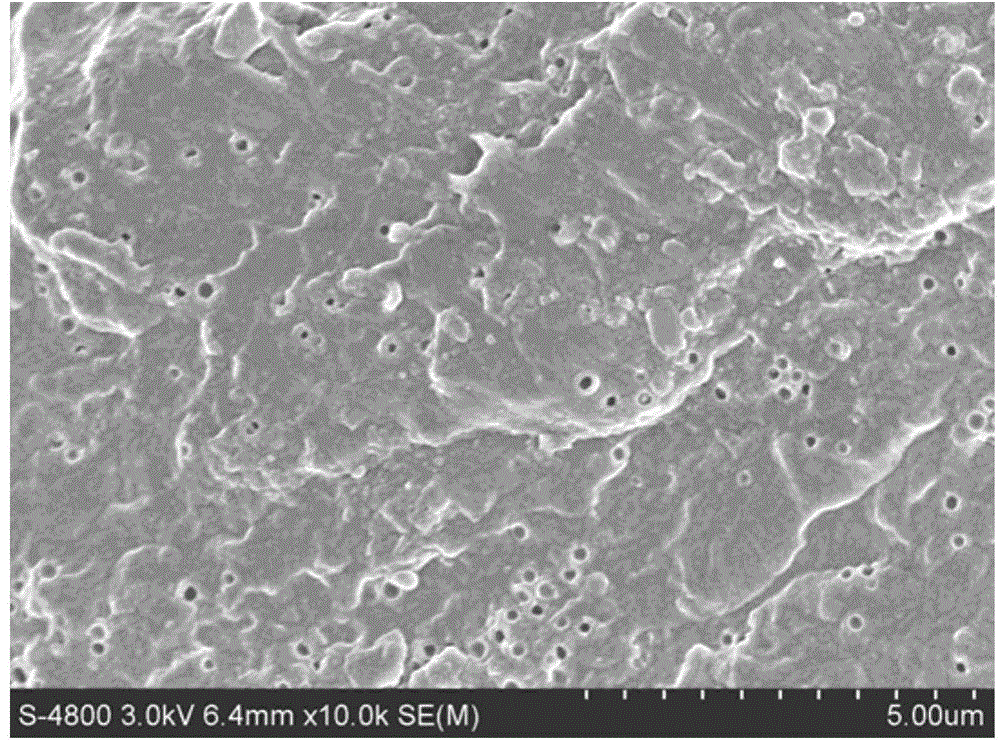

[0035] Example 2: Preparation of a composite membrane containing sulfonic acid functionalized hollow nano hydrogel.

[0036] The composite membrane has a thickness of 88 μm and is composed of 12.5 g of polyoxyethylene-polycaprolactam block copolymer with a mass fraction of 4% and 0.05 g of functionalized hollow nano-hydrogel, wherein the polyoxyethylene segment accounts for the block 60% of the mass fraction of the copolymer, the polycaprolactam segment accounts for 40% of the mass fraction of the block copolymer, and the functional group selected for the functionalized hollow nano hydrogel is a sulfonate group, and its preparation method is different from that of the above-mentioned Example 1 The only difference is that in step 3, the dosage of the sulfonic acid-functionalized hollow nano-hydrogel was changed from 0.025 g to 0.05 g, and a homogeneous sulfonic acid-functionalized hollow nano-hydrogel composite membrane with a thickness of 88 μm was finally obtained. figure 2 ...

Embodiment 3

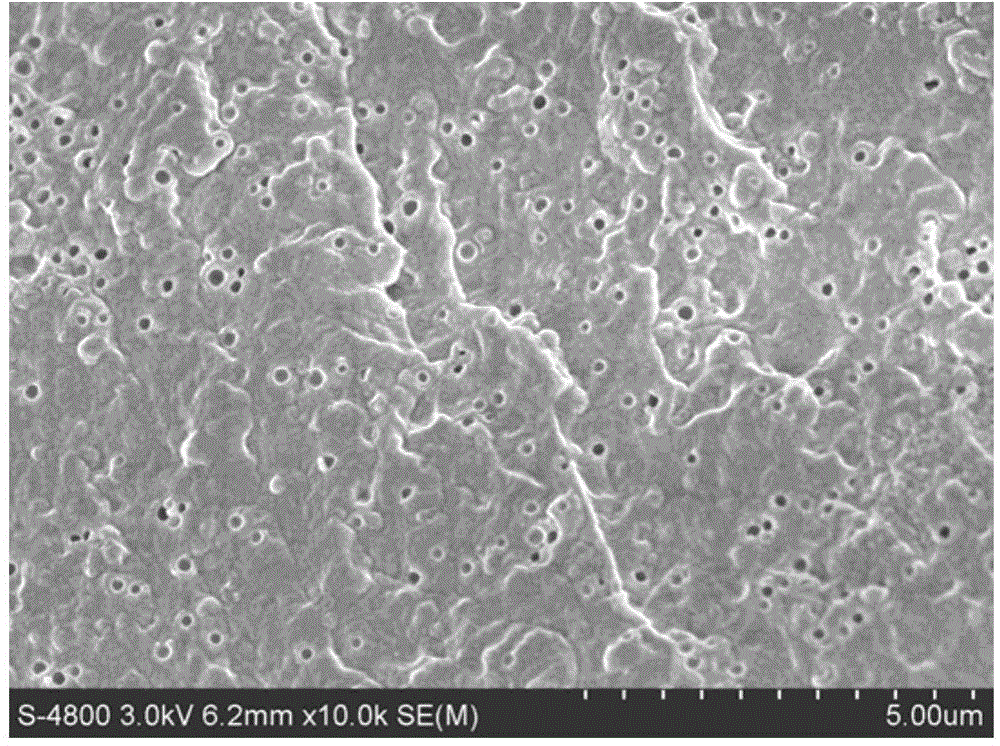

[0038] Example 3: Preparation of a composite membrane containing sulfonic acid functionalized hollow nano hydrogel.

[0039] The composite membrane has a thickness of 93 μm and is composed of 12.5 g of polyoxyethylene-polycaprolactam block copolymer with a mass fraction of 4% and 0.075 g of functionalized hollow nano-hydrogel, wherein the polyoxyethylene segment accounts for the block 60% of the mass fraction of the copolymer, the polycaprolactam segment accounts for 40% of the mass fraction of the block copolymer, and the functional group selected for the functionalized hollow nano hydrogel is a sulfonate group, and its preparation method is different from that of the above-mentioned Example 1 The only difference is that in step 3, the dosage of the sulfonic acid-functionalized hollow nano-hydrogel was changed from 0.025 g to 0.075 g, and a homogeneous sulfonic acid-functionalized hollow nano-hydrogel composite membrane with a thickness of 93 μm was finally obtained. image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Co2 permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com