Preparation technology of carbon and rare earth element doped nanometer titanium dioxide ternary photocatalyst

A technology of nano-titanium dioxide and rare earth element is applied in the field of preparation technology of nano-titanium dioxide ternary photocatalyst, which can solve the problems of low utilization rate of sunlight and inability to improve catalytic efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

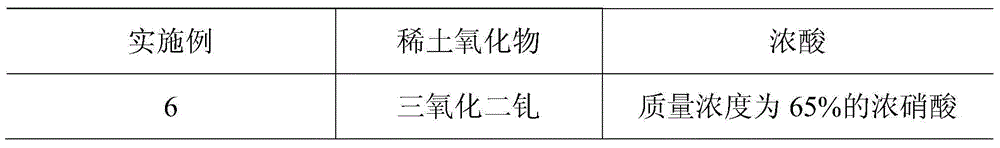

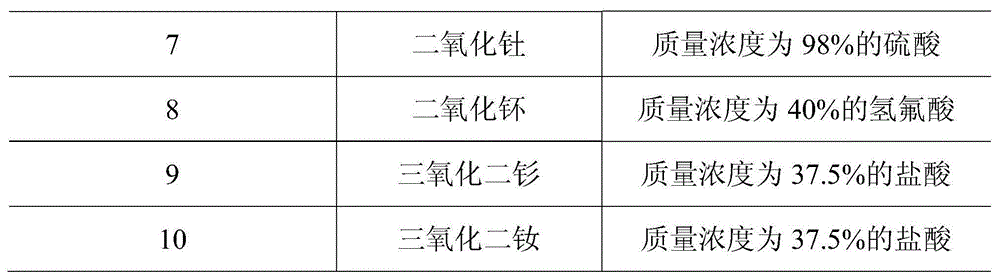

Examples

Embodiment 1

[0023] 1) Weigh 2.5 grams of lanthanum oxide with an electronic balance and place it in a beaker, then weigh 3.5 grams of concentrated nitric acid with a mass concentration of 65% and slowly pour it into the beaker containing lanthanum oxide, and stir continuously until dissolved at 50°C to prepare into a lanthanum nitrate solution, and then dry the lanthanum nitrate solution in a drying oven at 55°C to obtain a lanthanum nitrate solid;

[0024] 2) Weigh 0.5 grams of lanthanum nitrate solid and add 25 milliliters of distilled water to make an aqueous solution of lanthanum nitrate; weigh 7.5 grams of titanium tetrachloride and carefully pour it into a constant pressure dropping funnel, and then drop it at a rate of 7 seconds / drop under stirring conditions. Add it dropwise to a conical flask filled with 30 ml of absolute ethanol, and control the temperature at 20°C during the dropping process to make a transparent titanium tetrachloride absolute ethanol solution; weigh 1.5 g of a...

Embodiment 2

[0027] 1) Weigh 4.5 grams of yttrium oxide with an electronic balance and put it in a beaker, then weigh 3.25 grams of concentrated nitric acid with a mass concentration of 65% and slowly pour it into the beaker filled with yttrium oxide, and stir continuously at 50°C until it dissolves. into yttrium nitrate solution, and then dry the yttrium nitrate solution in a drying oven at 55°C to obtain yttrium nitrate solid;

[0028] 2) Weigh 0.35 grams of yttrium nitrate solid and add 25 milliliters of distilled water to make an aqueous solution of yttrium nitrate; weigh 8.5 grams of titanium tetrachloride and carefully pour it into a constant pressure dropping funnel, then drop it at a rate of 7 seconds / drop under stirring conditions. Add dropwise to a conical flask filled with 30 ml of absolute ethanol, and control the temperature at 20°C during the dropping process to make a transparent titanium tetrachloride absolute ethanol solution; weigh 1.35 g of ammonium carbonate and add 6 ml...

Embodiment 3

[0031] 1) Weigh 3.5 grams of europium oxide with an electronic balance and place it in a beaker, then weigh 2.75 grams of concentrated nitric acid with a mass concentration of 65% and slowly pour it into the beaker containing europium oxide, and stir continuously until dissolved at 50 ° C to prepare into a europium nitrate solution, and then dry the europium nitrate solution in a drying oven at 40°C to obtain a europium nitrate solid;

[0032] 2) Weigh 0.4 grams of europium nitrate solid and add 30 milliliters of distilled water to make an aqueous solution of europium nitrate; weigh 9.5 grams of titanium tetrachloride and carefully pour it into a constant pressure dropping funnel, and then drop it at a rate of 10 seconds / drop under stirring conditions. Add dropwise to a conical flask filled with 30 ml of absolute ethanol, and control the temperature at 25°C during the dropping process to make a transparent titanium tetrachloride absolute ethanol solution; weigh 5 grams of ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com