Preparation method of composite titanium dioxide photocatalyst activated carbon based on g-carbon nitride

A titanium dioxide and carbon nitride technology, applied in chemical instruments and methods, physical/chemical process catalysts, other chemical processes, etc., can solve the problems of difficult to control the manufacturing process, high production cost, low activated carbon activity, etc. The effect of uniform reactivity, efficient adsorption of pollutants, and improved capture capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

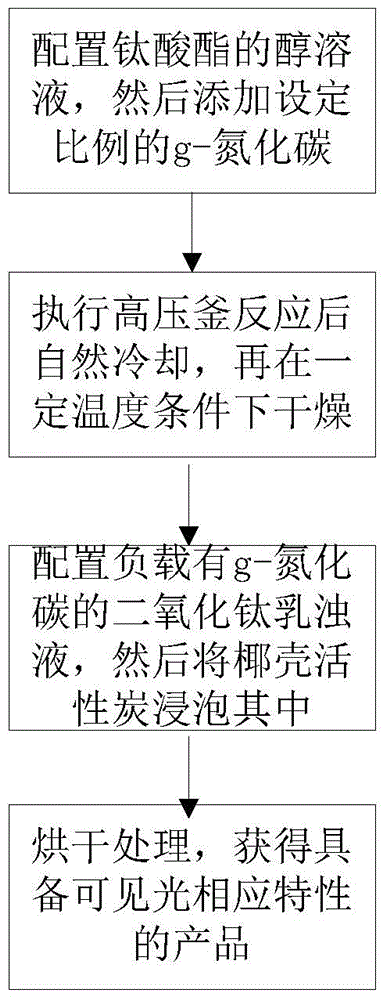

[0023] Dissolve tetrabutyl titanate in ethanol as a solute, stir evenly at room temperature, transfer the reaction solution to a 100 ml Teflon reaction bottle, and then add 0.3 g of g-carbon nitride particles per 100 ml of solution Add by way of adding, and after stirring evenly, obtain mixed solution, this g-carbon nitride particles can be made, for example, by thermal condensation polymerization, melamine thermal condensation, and its average particle diameter is preferably about 5 nanometers;

[0024] Next, put the Teflon reaction bottle into the stainless steel jacket, tighten the stainless steel cover, place it in the heating box, set the heating temperature to 210°C, and the reaction time is 210 minutes. After the reaction is over, let the reaction kettle cool down naturally. At room temperature, the reaction product was collected by centrifugation, washed three times with ethanol, and the obtained powder was dried in an oven at 60 degrees for 30 minutes to obtain titaniu...

Embodiment 2

[0027] Dissolve tetrabutyl titanate in ethanol as a solute, stir evenly at room temperature, transfer the reaction solution to a 100 ml Teflon reaction bottle, and then add 0.35 g of g-carbon nitride particles per 100 ml of solution Add by way of adding, and after stirring evenly, obtain mixed solution, this g-carbon nitride particles can be made, for example, by thermal condensation polymerization, melamine thermal condensation, and its average particle diameter is preferably about 5 nanometers;

[0028] Next, put the Teflon reaction bottle into the stainless steel jacket, tighten the stainless steel cover, place it in the heating box, set the heating temperature to 180°C, and the reaction time is 240 minutes. After the reaction is over, let the reaction kettle cool down naturally. At room temperature, the reaction product was collected by centrifugation, washed three times with ethanol, and the obtained powder was dried in an oven at 55 degrees for 60 minutes to obtain titani...

Embodiment 3

[0031] Dissolve tetrabutyl titanate in ethanol as a solute, stir evenly at room temperature, transfer the reaction solution to a 100 ml Teflon reaction bottle, and then add 0.4 g of g-carbon nitride particles per 100 ml of solution Add by way of adding, and after stirring evenly, obtain mixed solution, this g-carbon nitride particles can be made, for example, by thermal condensation polymerization, melamine thermal condensation, and its average particle diameter is preferably about 6 nanometers;

[0032] Next, put the Teflon reaction bottle into the stainless steel jacket, tighten the stainless steel cover, place it in the heating box, set the heating temperature to 240°C, and the reaction time is 120 minutes. After the reaction is over, let the reaction kettle cool down naturally. At room temperature, the reaction product was collected by centrifugation, washed three times with ethanol, and the obtained powder was dried in an oven at 55 degrees for 60 minutes to obtain titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com