Method for preparing nano FeOx/NiOy/mesoporous material catalyst, product and application of nano FeOx/NiOy/mesoporous material catalyst

A technology of mesoporous materials and catalysts, applied in the research field of catalyst materials, to achieve the effect of not easy to lose, improve activity and reaction rate, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

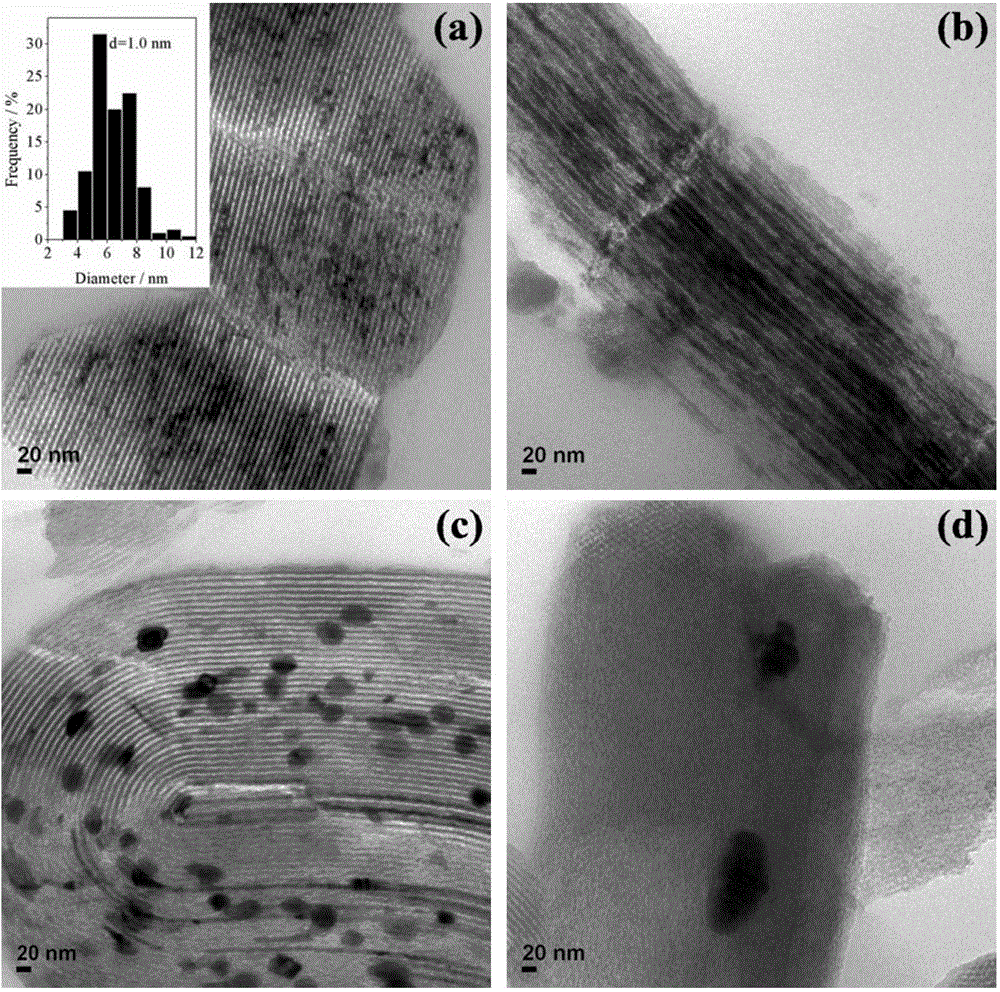

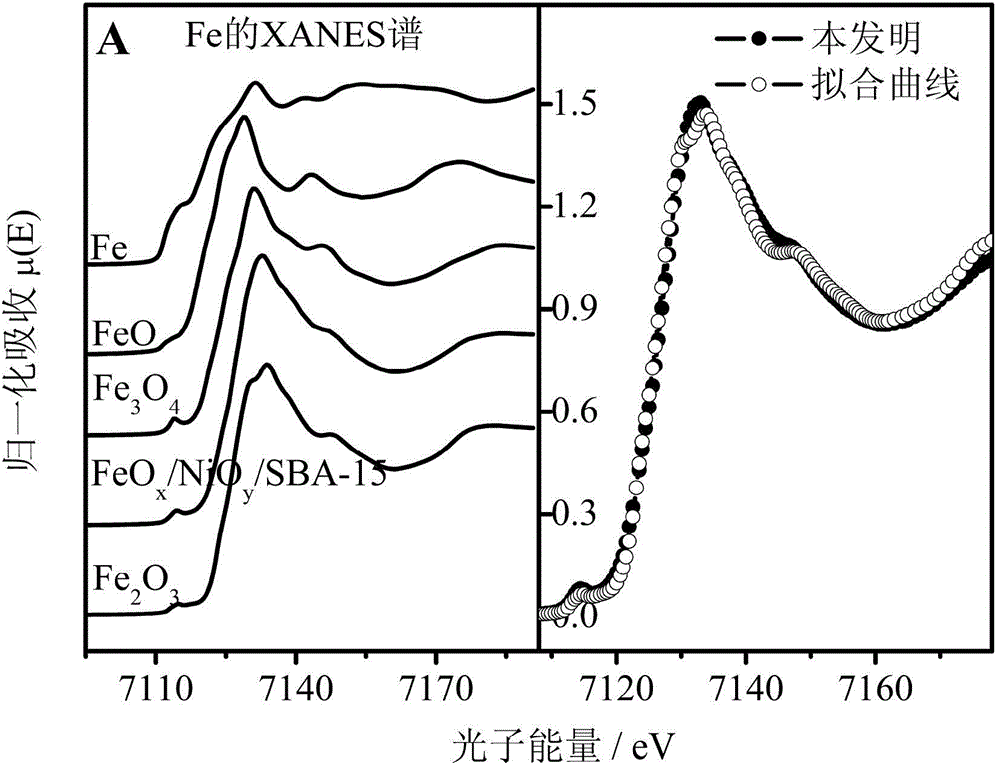

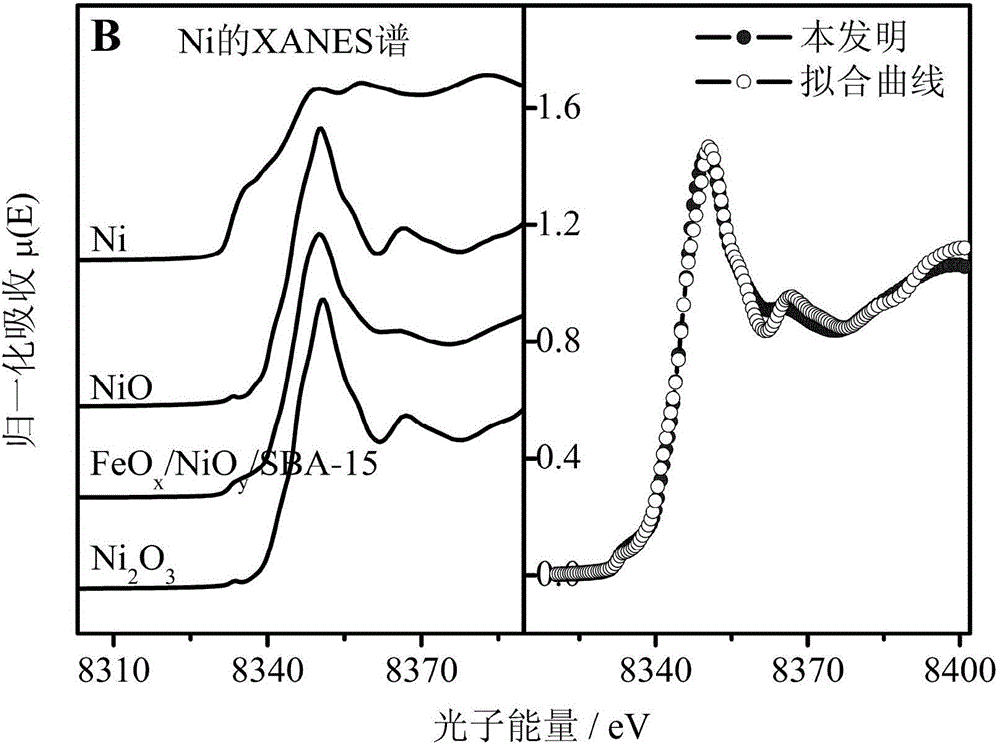

[0040] Take 1g of mesoporous SBA-15 (SiO 2 / Al 2 o 3 ≥500, BET:400-600m 2 / g, pore size 6-8nm) sample, equal volume impregnated in the content of 8.953×10 -4 mol of NiCl 2 In the aqueous solution, air-dry at room temperature, dry in an oven at 105°C to remove residual moisture, and place in a tube furnace for calcination at 400°C for 4 hours. After roasting, the sample is impregnated in an equal volume at a content of 8.953×10 -4 mol of Fe(NO 3 ) 3 In the aqueous solution, dry at 105°C and bake at 400°C for 4 hours. The obtained sample was placed in a tube furnace, H 2 Reduction at 300°C for 2 hours under atmospheric conditions to obtain FeO x / NiO y / SBA-15 catalyst.

Embodiment 2

[0042] Take 1g of mesoporous SBA-15 (SiO 2 / Al 2 o 3 ≥500, BET:400-600m 2 / g, pore size 6-8nm) sample, equal volume impregnated in the content of 8.953×10 -4 mol of Fe(NO 3 ) 3 In the aqueous solution, air-dry at room temperature, dry in an oven at 105°C to remove residual moisture, and place in a tube furnace for calcination at 400°C for 4 hours. After roasting, the sample is impregnated in an equal volume at a content of 8.953×10 -4 mol of NiCl 2 In the aqueous solution, dry at 105°C and bake at 400°C for 4 hours. The obtained sample was placed in a tube furnace, H 2 Reduction at 300°C for 2 hours under atmospheric conditions to obtain NiO y / FeO x / SBA-15 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com