Mechanical energy collecting system and method thereof

A technology of energy collection and machinery, which is applied in current collectors, electric vehicles, electrical components, etc., and can solve problems such as loss and waste of mechanical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

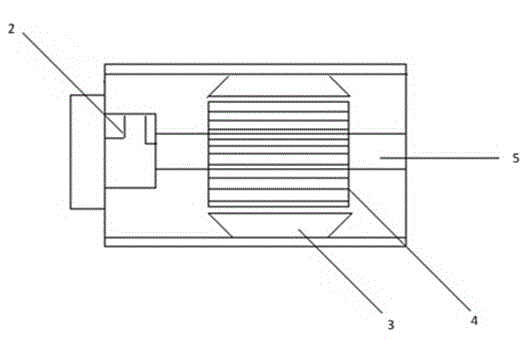

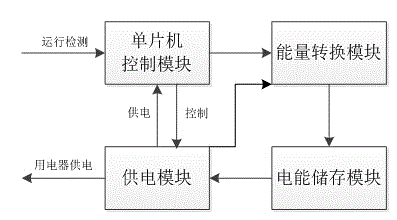

[0022] A mechanical energy harvesting system for energy harvesting when trains and cars brake, including:

[0023] The single-chip microcomputer control module, the energy conversion module, the electric energy storage module and the power supply module, the single-chip microcomputer control module monitors the operation of the vehicle, and judges whether the vehicle is running normally or braking. During normal operation, the single-chip microcomputer has no output. , the single-chip microcomputer control module controls the current of different sizes to flow into the main excitation pole of the energy conversion module, adjusts the amplitude of energy conversion, reduces the loss of the vehicle braking device, and improves vehicle performance. The energy conversion module is a small DC generator or a small AC generator machine, the electric energy storage module is the battery charging circuit and the battery, the power supply module is the power supply for the single-chip mi...

Embodiment 2

[0035] The existing low-power mechanical generator is refitted, and the main terminal of the excitation is left to be controlled by the drive module of the single-chip microcomputer. The LR160-708 9-tube low-power generator can be refitted to obtain the energy conversion module required by the system. .

Embodiment 3

[0037] The electric energy storage module can preferably be an ES-D (1500W) series charger or a similar charger and a 46B24LR12V45AH battery or a battery with a larger capacity. The single-chip microcomputer monitors the equipment that needs to use electric energy, and issues commands to the power supply module, and the power supply module supplies power to the modules that need power supply according to the received instructions to achieve the function of intelligent control. Considering the cost, you can use STC89C52RC-40I-PDIP40, and considering the performance, you can choose it for ATMEGA169PA-AU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com