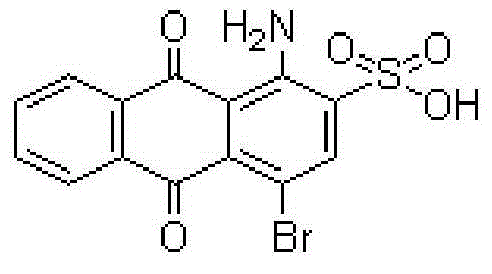

Method for treating waste acid generated in production process of bromamine acid

A technology of production process and treatment method, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor decolorization effect, difficult and ineffective waste acid treatment Remove waste acid organic matter and other problems, to achieve the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get the waste acid 200ml (CODcr=32500 mg / liter, sulfuric acid acid value 38%) that solvent method produces bromonic acid to produce, be cooled to 20 ℃, after standing and settling for 8 hours, filter. After filtration, the filtrate ICODcr=26480 mg / L. The filtrate was added with 20 g of sodium hypochlorite (available chlorine 9.8%) under stirring, and the addition time was 0.5 hour. After the addition, stir at room temperature for 4 hours, then raise the temperature to 60° C., keep the temperature for 2 hours, and then filter. After filtering the filtrate II CODcr=435mg / liter, the acid value of sulfuric acid is 33%.

Embodiment 2

[0028] Get 200ml of waste acid (CODcr=32500 mg / liter, sulfuric acid acid value 38%) that the solvent method produces bromonic acid to produce, cool down to 25 ℃, after standing and settling for 8 hours, filter. After filtration, the filtrate ICODcr=27790 mg / L. The filtrate was added with 20 g of sodium hypochlorite (available chlorine 9.8%) under stirring, and the addition time was 0.5 hour. After the addition, stir at room temperature for 4 hours, then raise the temperature to 60° C., keep the temperature for 2 hours, and then filter. After filtering the filtrate II CODcr=483mg / liter, the acid value of sulfuric acid is 33.4%.

Embodiment 3

[0030] Get 200ml of waste acid (CODcr=32500 mg / liter, sulfuric acid acid value 38%) that solvent method produces bromonic acid to produce, cool down to 10 ℃, after standing and settling for 8 hours, filter. After filtration, the filtrate ICODcr=26210 mg / L. The filtrate was added with 20 g of sodium hypochlorite (available chlorine 9.8%) under stirring, and the addition time was 0.5 hour. After the addition, stir at room temperature for 4 hours, then raise the temperature to 60° C., keep the temperature for 2 hours, and then filter. Filtrate II CODcr=440 mg / liter after filtration, sulfuric acid acid value 32.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com