Nano-silver-particle-embedded porous ceramic sheet as well as preparation method and application thereof

A technology of nano-silver particles and porous ceramics, which is applied in the field of drinking water disinfection technology and ceramic water purification, which can solve the problems of affecting the utilization efficiency of raw materials, the functional efficiency of water purification materials, the loss of anions, nano-silver, secondary pollution, etc., and achieve the saving of silver consumption , not easy to fall off, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

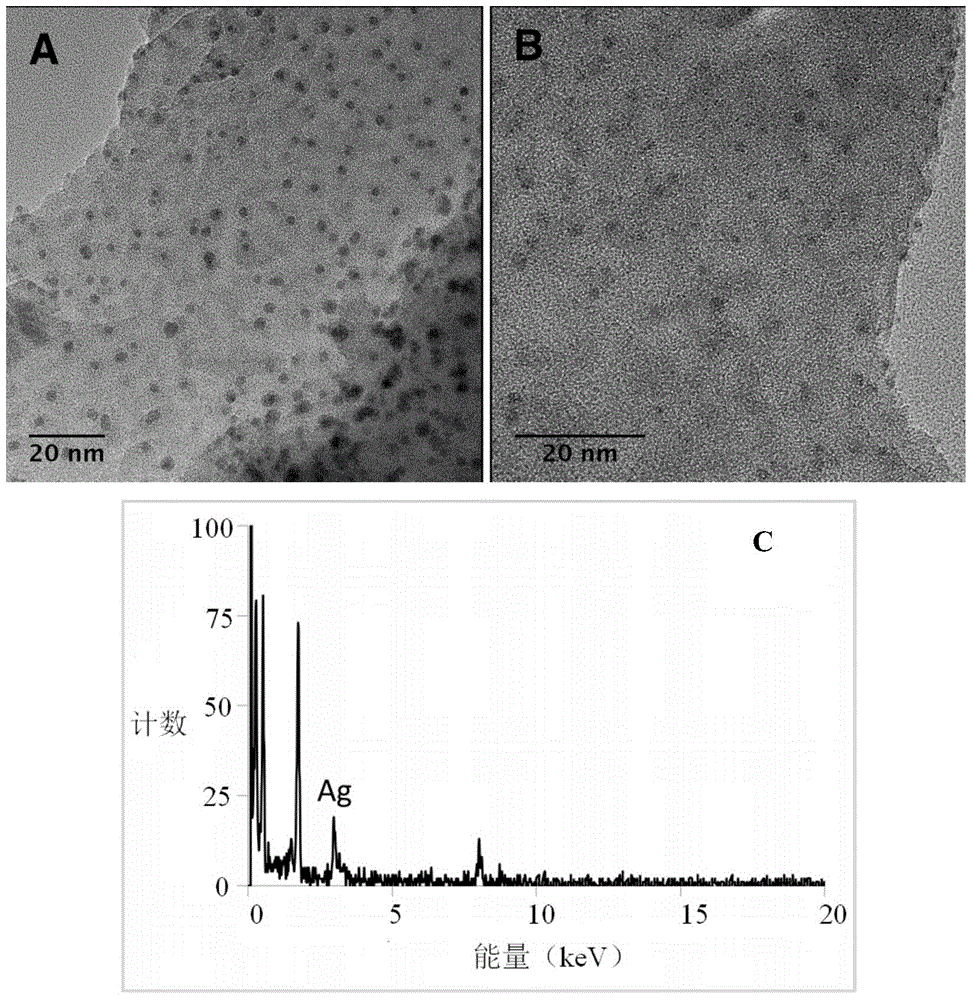

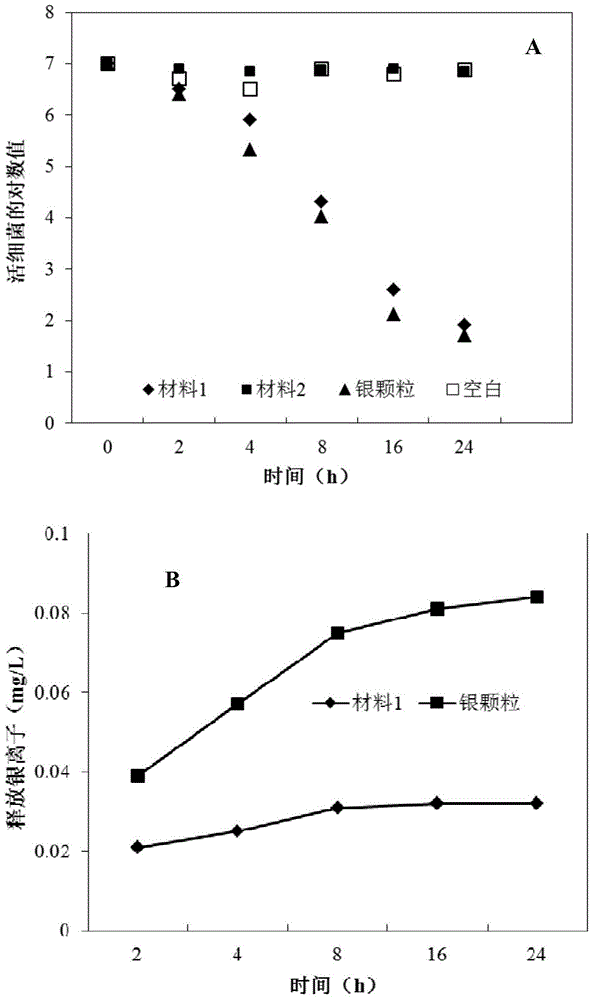

Embodiment 1

[0032] Preparation of porous ceramic water purification material: Prepare 62.5g of the mixture with a mixing ratio of clay and wood chips of 9:1. The characteristics of the clay used are: the clay is purchased from Sigma-Aldrich Company, and its main components are kaolinite and illite , the particle size distribution of the clay is that the particles 20μm respectively account for 28wt%, 56wt%, and 16wt%; in addition, the sawdust is obtained by passing through a 20-mesh sieve. Add the mixture of clay and sawdust to 19.2ml of silver nitrate solution with a concentration of 1.3mol / L, and disperse the mixture with ultrasonic wave for 1-2h, then stir evenly, fix the mixture into a disc with a diameter of 80mm and a thickness of 30mm with a manual hydraulic press, and Air dry at room temperature for 72 hours. Then place the wafer in a kiln and raise the temperature to 600°C at 2.5°C / min, then raise the temperature to 900°C at 5°C / min, and then keep it warm for 3 hours to obtain Mat...

Embodiment 2

[0037] It is basically the same as Example 1, except that the mass of silver nitrate added to the mixture is 1 g, and the prepared material is marked as material 3.

[0038] It is basically the same as Example 1, except that the mixture is fixed into a disc with a diameter of 80 mm and a thickness of 20 mm by a manual hydraulic press, and the prepared material is designated as Material 4.

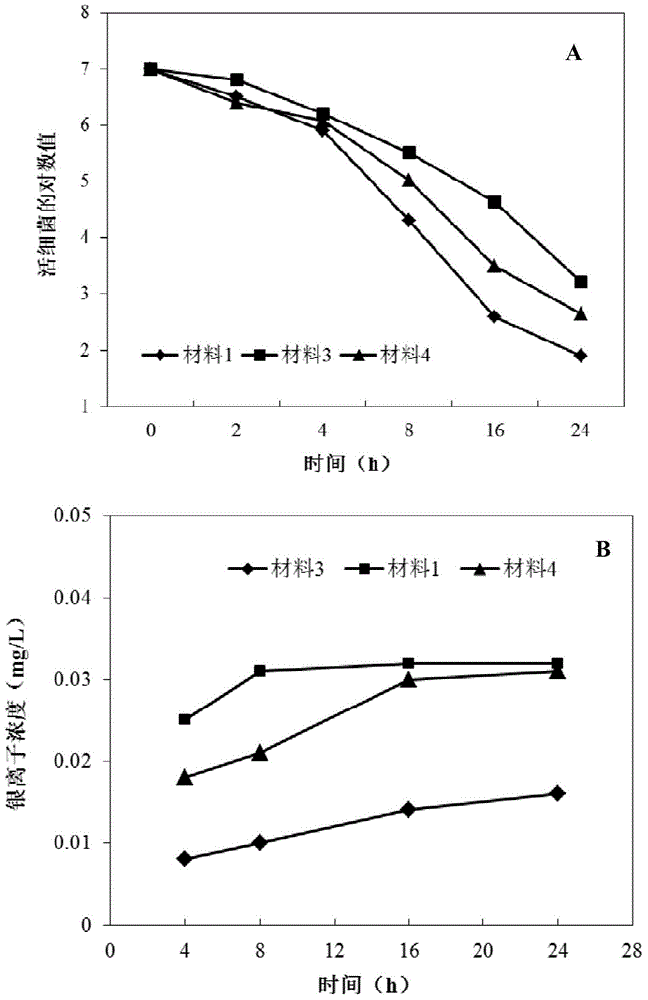

[0039]Sterilization test: The three porous ceramic water purification materials (material 1, material 3 and material 4) prepared above were used to kill Escherichia coli in water. Add three different porous ceramic water purification materials into the phosphate buffer solution containing 200mL E. coli respectively, wherein the concentration of phosphate buffer is 10mmol / L and the concentration of E. coli is 10 7 cfu / L. Samples were taken according to the set time, and the number of E. coli and the concentration of silver ions were measured. For relevant test results, see image 3 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com