Flame heating type thermal noise combined environment testing device

An environmental test device and flame heating technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of insufficient heating capacity and decreased heating capacity of quartz lamp heaters, and achieve improved heating capacity and noise resistance Strong ability and guaranteed safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

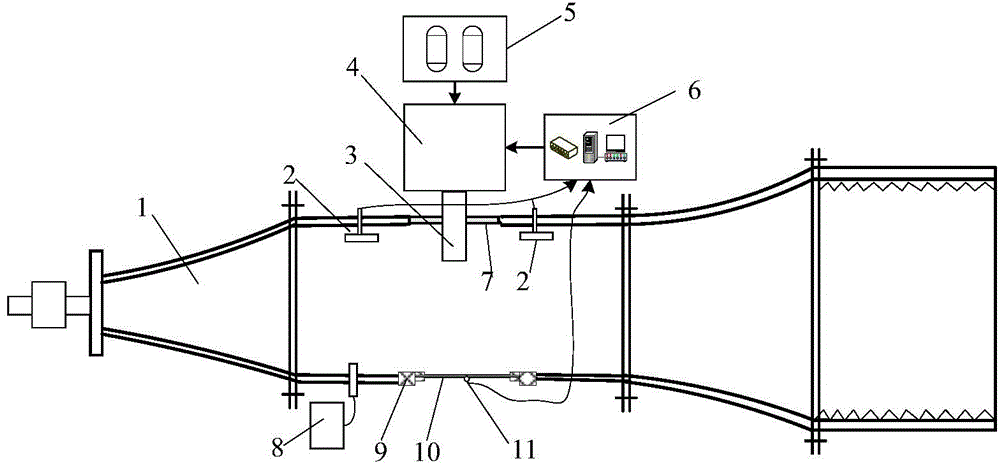

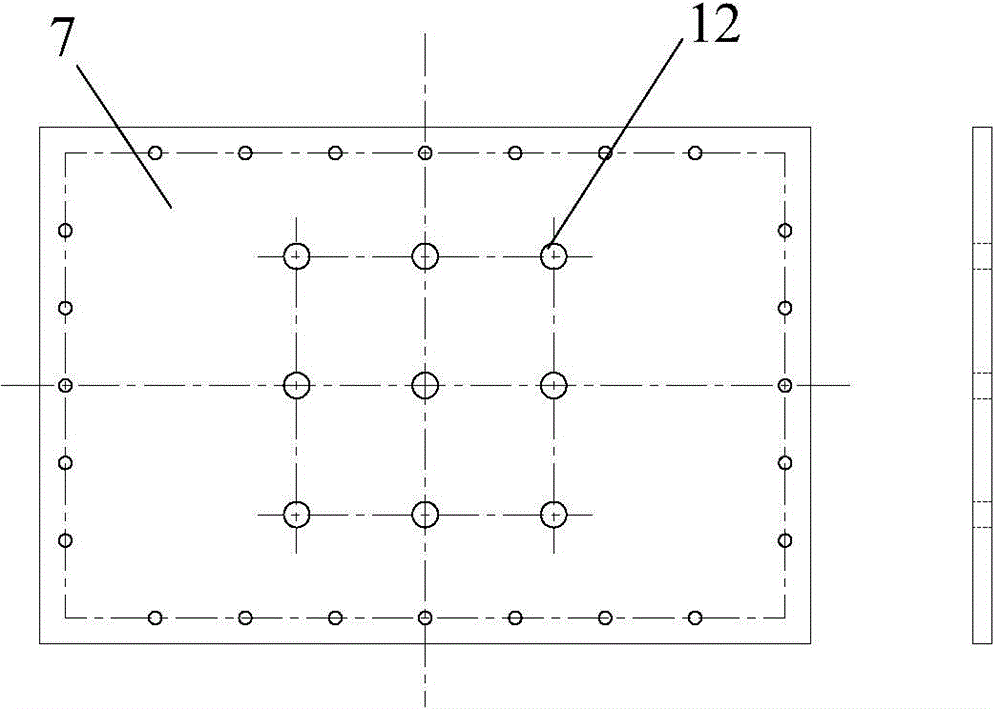

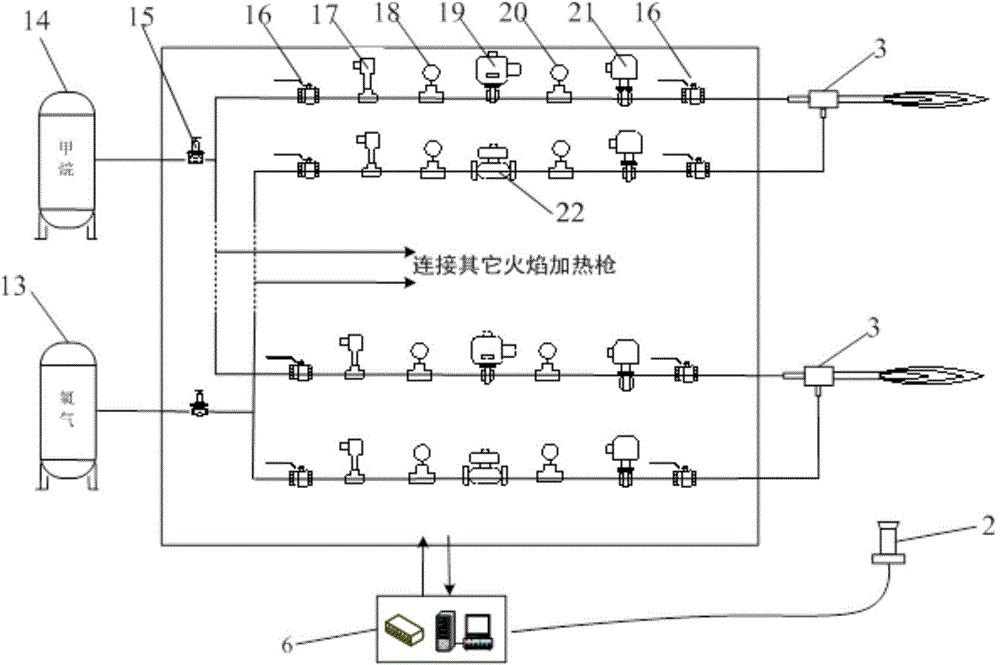

[0028] The present invention is a kind of flame heating thermal noise composite environment simulation test device, such as figure 1 As shown, it includes traveling wave tube noise device 1, flame monitor 2, flame heating gun 3, flame pipeline system 4, flame gas supply system 5, flame control system 6, flame heating gun mounting plate 7, noise measurement and control system 8, A test piece fixture 9, a test piece 10 and a temperature measurement and control system including a temperature measuring point 11. The test pieces are metal or high temperature composite material test pieces.

[0029] Wherein, the traveling wave tube noise device 1 includes an electric loudspeaker for generating noise, a horn, a test section, a diffusion section and a noise-absorbing section, and each component is connected in sequence. The noise measurement and control syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com