A kind of nitride high electron mobility transistor epitaxial structure and preparation method thereof

A technology with high electron mobility and epitaxial structure, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem of destroying surface morphology, deteriorating GaN/InAlN interface quality, and reducing channel two-dimensional electron gas transport characteristics and other issues, to avoid damage and improve the effect of transport characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

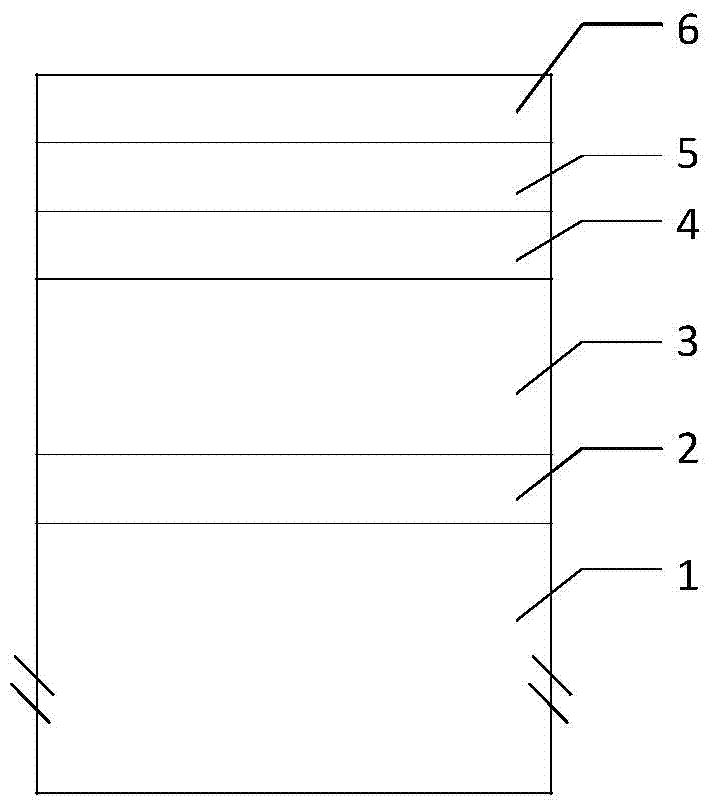

[0023] 1) Select the C-plane SiC substrate and grow it by MOCVD technology;

[0024] 2) Baking at 1080°C and 100Torr in a hydrogen atmosphere for 10 minutes;

[0025] 3) At 1100°C, inject ammonia gas and trimethylaluminum, and grow a 50nm thick AlN nucleation layer on the substrate surface;

[0026] 4) Introduce ammonia gas and trimethylgallium to grow a 2um thick N-polar GaN buffer layer;

[0027] 5) Turn off trimethylgallium, lower the temperature to 780°C, turn on trimethylaluminum and trimethylindium, and grow the first InAlN barrier layer with a thickness of 20nm and a constant In composition of 0.18;

[0028] 6) Keep the flow rate of trimethylaluminum and trimethylindium constant, and gradually increase the growth temperature to 1050°C, and at the same time grow InAlN with a thickness of 15nm and a gradient composition, which is the second barrier layer;

[0029]7) At 1050°C, turn off trimethylaluminum and trimethylindium, turn on trimethylgallium, and grow a 20nm thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com