Preparation method of carbon-supported nano platinum alloy catalyst

A technology of alloy catalyst and nano-platinum, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems affecting the uniformity of catalyst composition performance, quality reduction, etc., to improve the area specific activity, Effect of reducing carbon loss and reducing carbon carrier loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

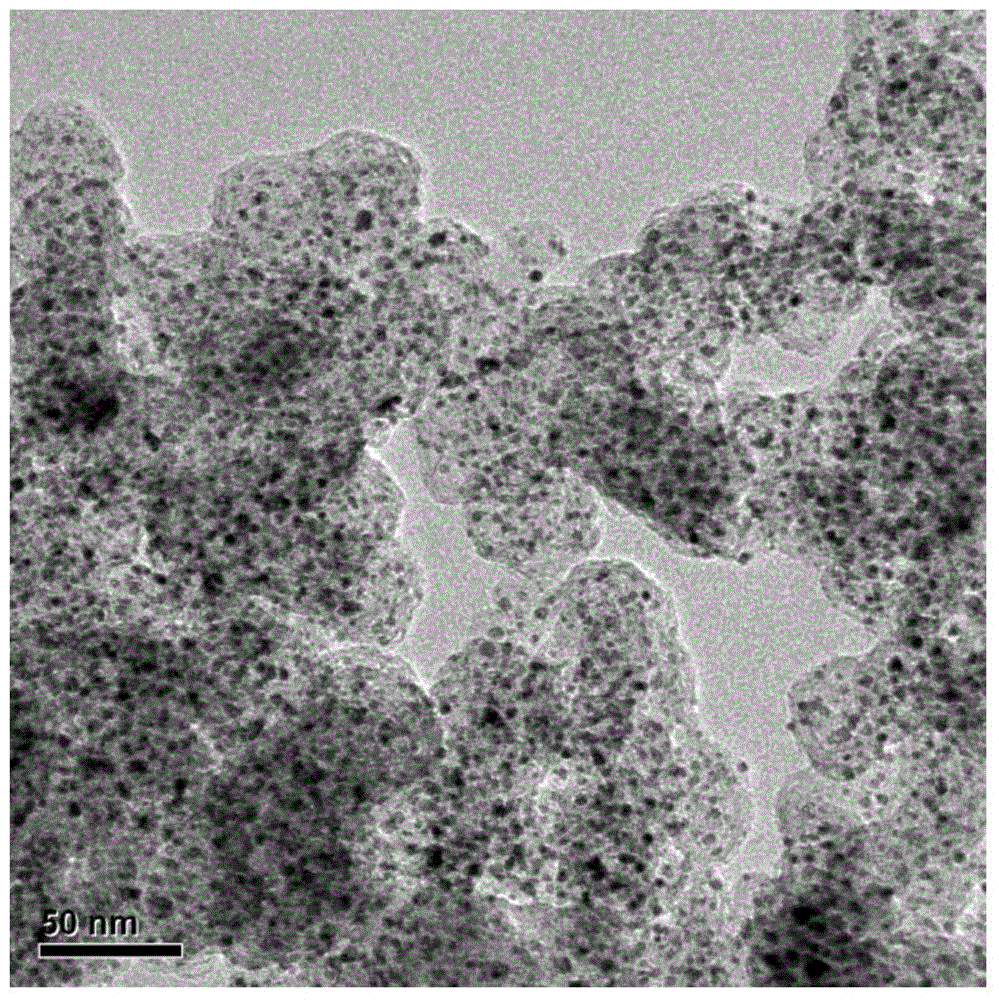

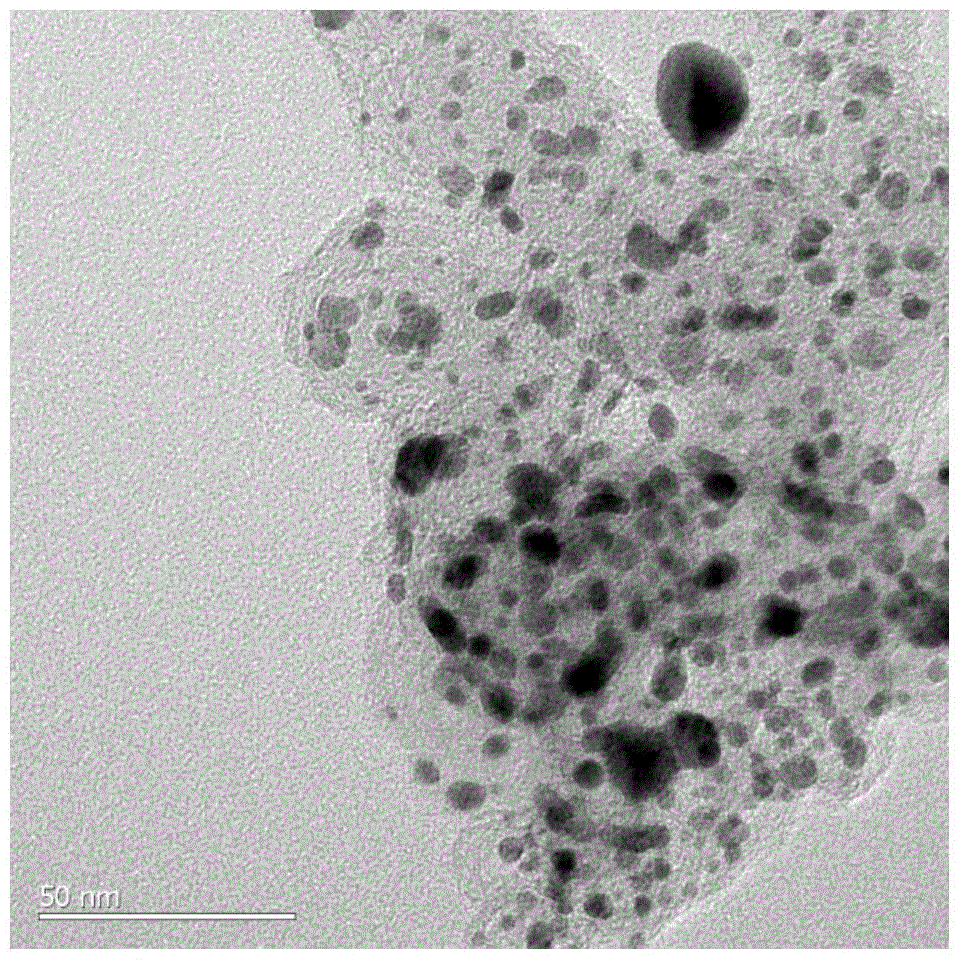

[0037] The present embodiment relates to a kind of preparation method of carbon-supported nanometer platinum alloy catalyst (Pt-alloy / C), described method comprises the steps:

[0038] Step 1, 1g Pt / C catalyst (platinum content is 30wt%) is added to 200ml acid copper sulfate solution (0.05M CuSO 4 , 0.05MH 2 SO 4 ), and ultrasonically disperse for 30mins, and remove oxygen for 30mins; the negative and anode materials are both graphite, and the reference electrode is a saturated calomel electrode. The three-electrode system is accompanied by a mechanical stirring device; the cathode is set at the underpotential deposition potential of Cu Nearby, maintain a constant potential for 2mins to obtain Cu-Pt / C.

[0039] Step 2, impregnating Cu-Pt / C in Co(NO 3 ) 2 ·6H 2 In the 20ml aqueous solution of O 2.695g, follow-up adopts the combination mode of ultrasonic and ordinary mechanical stirring, ultrasonic 30mins, ordinary mechanical stirring 30mins, repeat twice, obtain Cu-Pt / C su...

Embodiment 2

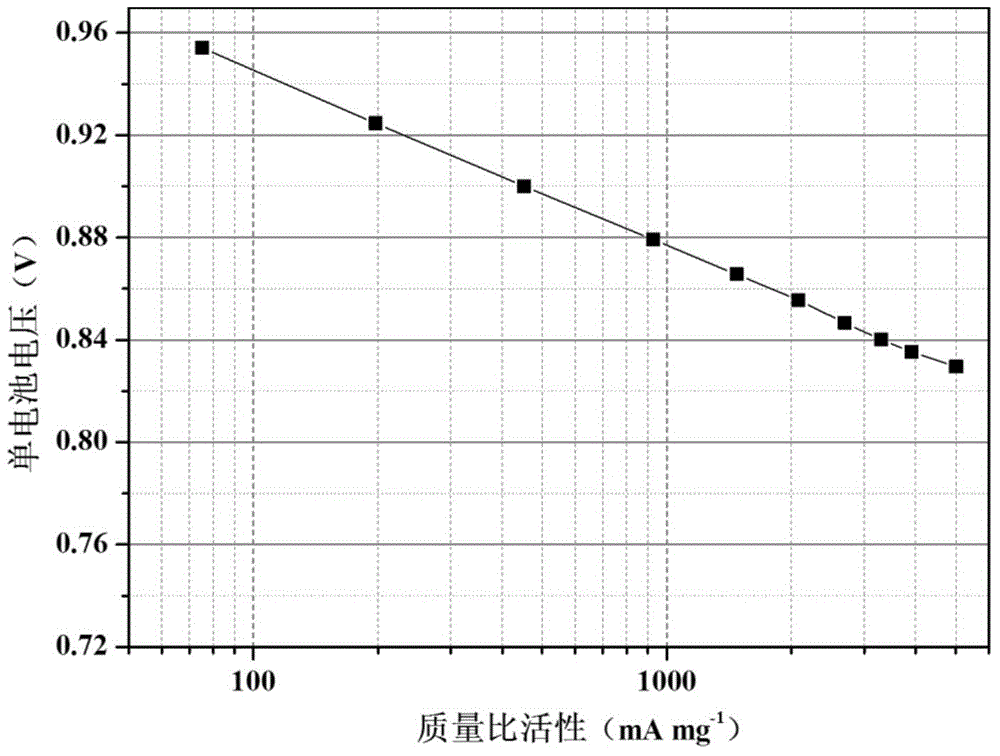

[0046] This embodiment is a modification of Embodiment 1, and the only difference is that in step 2, the 3d transition metal ions are derived from nickel nitrate.

[0047] Effect: The mass specific activity value of the catalyst prepared in this example measured at a voltage of 0.9V is 0.48A mg Pt -1 .

Embodiment 3

[0049] This embodiment is a modification of Embodiment 1, and the only change is that in step 2, Co(NO 3 ) 2 ·6H 2 The concentration of O is 0.20mmol / L.

[0050] Effect: The mass specific activity value of the catalyst prepared in this example is 0.45Amg when the cell voltage is 0.9V Pt -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com