Multi-ion adsorption material prepared by inorganic ion doping and large-steric-hindrance organic modification

A technology of adsorption materials and inorganic ions, which is applied in the field of environment and materials, can solve the problems that adsorption materials cannot be adsorbed at the same time, acid and alkali are difficult to coexist, and achieve the effects of environmental protection, regular channels, and avoiding spontaneous neutralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

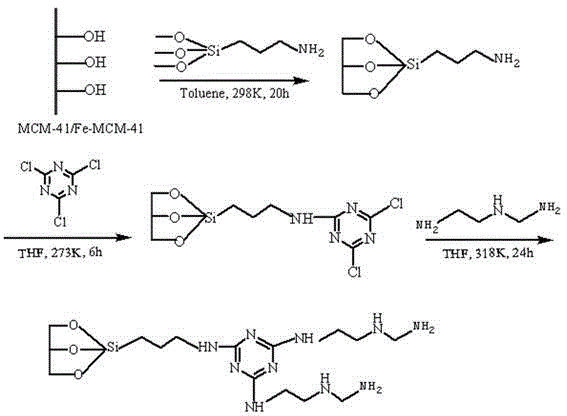

[0023] A multi-ion adsorption material prepared by inorganic ion doping and large steric hindrance organic modification, the preparation method specifically includes the following steps:

[0024] 1) Mix the aqueous solution containing 0.4318g ferric nitrate with 4mL TEOS and 68mL ethanol, add 20mL NH 4 OH solution was stirred until clear;

[0025] 2) Then add 100mL of an aqueous solution in which 1g of CTBA is dissolved, stir and react at room temperature for 3h, then undergo hydrothermal crystallization, filtration, washing, drying, and calcination to synthesize Fe-MCM-41 with a Si / Fe ratio of 10;

[0026] 3) After drying the synthesized Fe-MCM-41 at 150°C, take 1.0g and add it to a toluene solution containing 5mL APTES, stir vigorously at room temperature for 20h, filter, wash the filter cake with a large amount of ethanol, and dry to obtain a white powder ;

[0027] 4) Add 1.0 g of the white powder obtained in step 3) into a saturated tetrahydrofuran solution containing 1...

Embodiment 2

[0031] A multi-ion adsorption material prepared by inorganic ion doping and large steric hindrance organic modification, the preparation method specifically includes the following steps:

[0032] 1) Mix the aqueous solution containing 0.4318g ferric nitrate with 4mL TEOS and 68mL ethanol, add 20mL NH 4 OH solution was stirred until clear;

[0033] 2) Then add 100mL of an aqueous solution in which 1g of CTBA is dissolved, stir and react at room temperature for 3h, then undergo hydrothermal crystallization, filtration, washing, drying, and calcination to synthesize Fe-MCM-41 with a Si / Fe ratio of 10;

[0034] 3) After drying the synthesized Fe-MCM-41 at 150°C, take 1.0g and add it to a toluene solution containing 5mL APTES, stir vigorously at room temperature for 20h, filter, wash the filter cake with a large amount of ethanol, and dry to obtain a white powder ;

[0035] 4) Add 1.0 g of the white powder obtained in step 3) into a saturated tetrahydrofuran solution containing 1...

Embodiment 3

[0039] A multi-ion adsorption material prepared by inorganic ion doping and large steric hindrance organic modification, the preparation method specifically includes the following steps:

[0040] 1) Mix the aqueous solution containing 0.04318g ferric nitrate with 4mL TEOS and 68mL ethanol, add 20mL NH 4 OH solution was stirred until clear;

[0041] 2) Then add 100mL of an aqueous solution in which 1g of CTBA is dissolved, stir and react at room temperature for 3h, then undergo hydrothermal crystallization, filtration, washing, drying, and calcination to synthesize Fe-MCM-41 with a Si / Fe ratio of 100;

[0042] 3) After drying the synthesized Fe-MCM-41 at 150°C, take 1.0g and add it to a toluene solution containing 5mL APTES, stir vigorously at room temperature for 20h, filter, wash the filter cake with a large amount of ethanol, and dry to obtain a white powder ;

[0043] 4) Add 1.0 g of the white powder obtained in step 3) into a saturated tetrahydrofuran solution containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com