A medium and low temperature vanadium-titanium-based SCR denitration catalyst and preparation method thereof

A denitration catalyst, vanadium-titanium-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

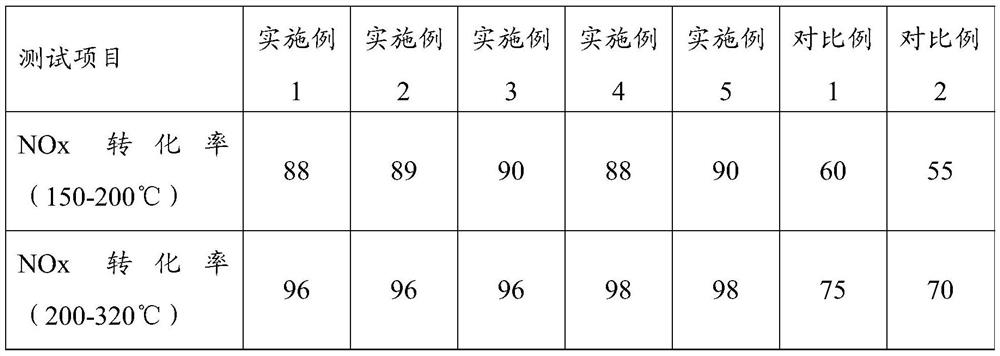

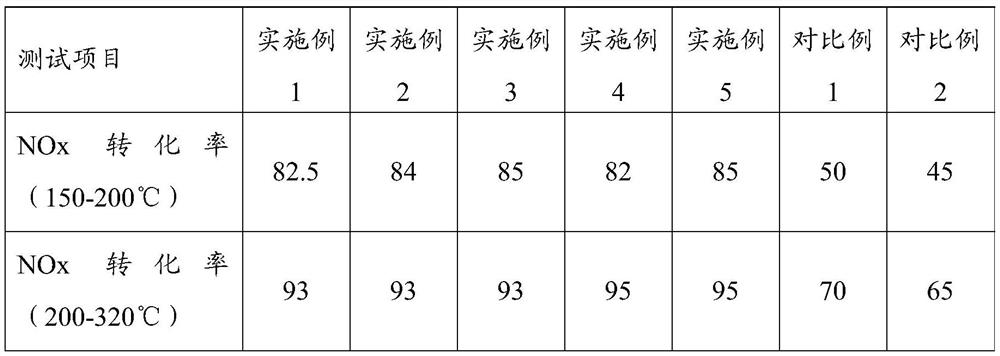

Examples

preparation example Construction

[0040] The preparation method of the medium-low temperature vanadium-titanium-based SCR denitration catalyst specifically includes the following steps:

[0041] 1S: Preparation of TiO 2 -SiO 2 carrier:

[0042]The glass microbeads, the first auxiliary agent, the second auxiliary agent, the alkali and the water are mixed, reacted at 20 to 80 ° C for 0.5 to 24 hours, and then filtered, washed and dried; wherein, the glass microbeads, the first auxiliary agent The water-solid ratio of the additive, the second additive and water is 0.05-0.5, the content of glass microbeads is 80-94.5%, the first additive is 2-5%, and the second additive is 0.5-18%; the alkali content is 1-94.5%. 7%; then the SiO 2 The base carrier and deionized water are prepared into a 5-20% suspension, the titanium donor and anhydrous ethanol are prepared into a solution with a titanium donor concentration of 0.2-5 mol / L, and then the suspension and the titanium solution are placed in the solution. After mix...

Embodiment 1

[0052] 1S: Preparation of TiO 2 -SiO 2 carrier:

[0053] Artificial glass microbeads, Ca(OH) 2 , sodium silicate and water are mixed according to the water-solid ratio of 0.15 and the alkali content of 2%. Among them, artificial glass beads, Ca(OH) 2 The contents of sodium silicate and sodium silicate are 80%, 5%, and 15% respectively; react at 40 ° C for 2 h, filter, wash, and dry for later use, thereby obtaining activated glass beads, namely SiO 2 base carrier. Then the SiO 2 The base carrier and deionized water are prepared into a 5% suspension, titanium tetrachloride and anhydrous ethanol are prepared into a solution with a titanium donor concentration of 0.5mol / L, and then the suspension and the titanium solution are mixed within 3h After completion, the pH value was controlled by hydrochloric acid to be 4, and the temperature was 60° C. After the reaction was carried out for 1 hour, it was allowed to stand for aging for 12 hours. Finally, the reaction product was f...

Embodiment 2

[0060] 1S: Preparation of TiO 2 -SiO 2 carrier:

[0061] The fly ash precipitated beads, calcium gluconate, sodium metasilicate and water are mixed according to the water-solid ratio of 0.05 and the alkali content of 3%. are 85%, 3%, and 12%; react at 50°C for 12 hours, filter, wash, and dry for later use, thereby obtaining activated glass beads, namely SiO 2 base carrier. Then the SiO 2 The base carrier and deionized water are prepared into an 8% suspension, titanium oxysulfate and anhydrous ethanol are prepared into a solution with a titanium donor concentration of 2.5mol / L, and then the suspension and the titanium solution are mixed within 2h. , the pH value was controlled to be 6 by hydrochloric acid, and the reaction temperature was 60 °C for 8 h, and then allowed to stand for 24 h. Finally, the reaction product was filtered and washed until the filtrate was clear, dried at 90°C, and calcined at 600°C for 2 h to obtain TiO 2 -SiO 2 vector.

[0062] TiO in this com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com